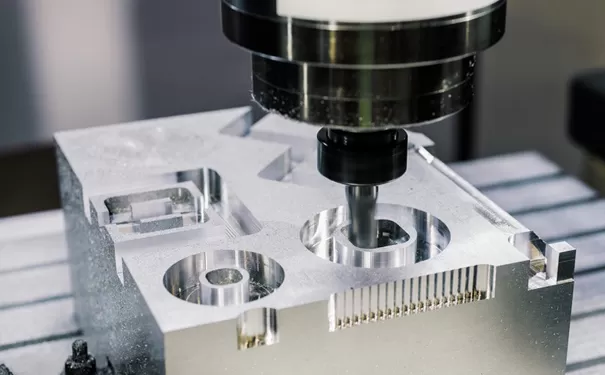

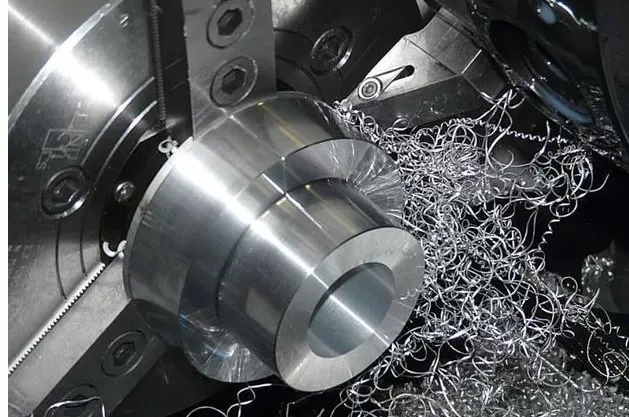

CNC machining is a manufacturing process that is widely used in the plastics industry. This process uses pre-programmed software to control the movement of tools and machinery, resulting in precise and accurate cuts and shapes. Here are some of the benefits of CNC machining for the plastics industry:

Precision and Accuracy

One of the biggest advantages of CNC machining is its ability to produce precise and accurate cuts and shapes. The computer program used in CNC machining allows for incredibly precise movements of the machine tool, resulting in finished products that meet exact specifications.

Consistency and Repeatability

CNC machining is highly repeatable, meaning that the same program can be used to produce the same part thousands of times. This consistency is essential in the plastics industry, where high volumes of identical parts are often required.

Versatility

CNC machines can be programmed to produce a wide range of parts and components, from simple to complex. This versatility makes it possible to create custom parts and components that meet the specific needs of customers.

Reduced Lead Times

CNC machining can produce parts much faster than traditional manufacturing methods, which can significantly reduce lead times. This is particularly important in the plastics industry, where fast turnaround times are often necessary.

Reduced Waste

CNC machining produces less waste than traditional manufacturing methods. This is because the computer program used in CNC machining allows for precise cuts and shapes, resulting in less material waste.

In conclusion, CNC machining is an essential process in the plastics industry, providing precision, consistency, versatility, reduced lead times, and reduced waste. By using CNC machining, manufacturers can create high-quality parts and components that meet the specific needs of their customers.

Cost-Effective

Although CNC machines can be expensive to purchase, they are cost-effective in the long run due to their efficiency and lower labor costs. CNC machines can operate around the clock with minimal supervision, reducing labor costs and increasing production capacity.

Improved Safety

CNC machining is a fully automated process that significantly reduces the risk of accidents and injuries. This is because the machine tool is controlled by a computer program, eliminating the need for manual labor and reducing the risk of human error.

Customization

CNC machining can be used to create custom parts and components that meet the specific needs of customers. This is particularly important in the plastics industry, where custom parts and components are often required to meet the unique needs of each project.

Quality

CNC machining produces high-quality parts and components that meet exact specifications. This is because the computer program used in CNC machining allows for precise cuts and shapes, resulting in finished products that are of consistent quality.

Conclusion

CNC machining is a valuable process for the plastics industry, providing precision, consistency, versatility, reduced lead times, reduced waste, cost-effectiveness, improved safety, customization, and quality. By using CNC machining, manufacturers can create high-quality parts and components that meet the specific needs of their customers, while also improving their bottom line. With the many benefits that CNC machining provides, it is no wonder that it has become an essential process in the plastics industry.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items