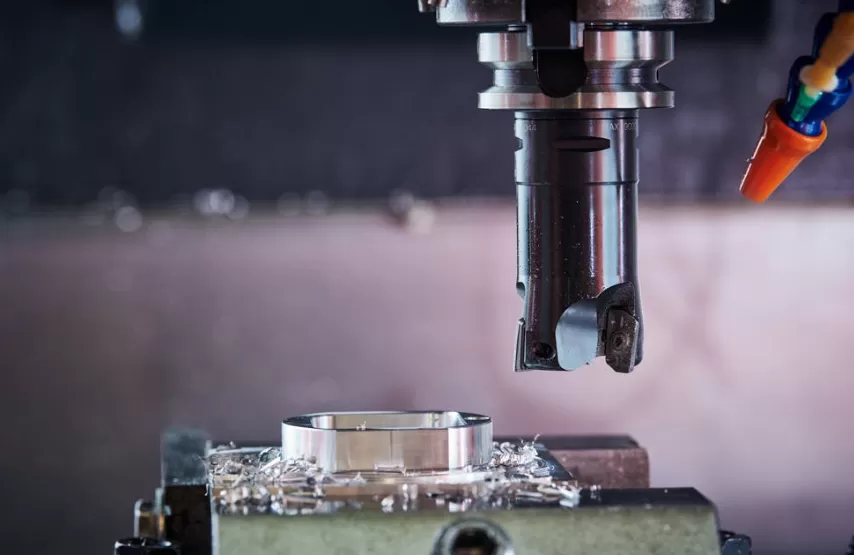

CNC milling machining is a highly precise and efficient manufacturing process that is ideal for prototyping. In this article, we will explore the benefits of CNC milling parts machining for prototyping and why it is the preferred method for many manufacturers.

Precision and Accuracy

CNC milling machining is known for its precision and accuracy, making it an ideal choice for prototyping. With CNC milling, manufacturers can create highly detailed and complex parts with consistent quality, ensuring that the prototype accurately represents the final product.

Speed and Efficiency

CNC milling machining is also incredibly fast and efficient, allowing manufacturers to produce prototypes quickly and cost-effectively. With the use of computer-controlled machines, manufacturers can create multiple prototypes at the same time, reducing lead times and improving turnaround times.

Versatility

Another benefit of CNC milling machining for prototyping is its versatility. CNC milling machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to produce prototypes in a variety of materials and test them for different properties.

Customization

CNC milling machining also allows for customization, which is essential for prototyping. With CNC milling, manufacturers can create unique and customized prototypes that meet specific requirements and specifications. This customization allows for greater flexibility in the prototyping process and can lead to better final products.

Cost-Effective

Finally, CNC milling machining is a cost-effective option for prototyping. With the ability to create multiple prototypes quickly and efficiently, manufacturers can reduce costs and improve profitability. Additionally, the precision and accuracy of CNC milling can reduce the need for costly rework or redesigns, further improving cost-effectiveness.

In conclusion, CNC milling machining is the preferred method for prototyping due to its precision, speed, versatility, customization, and cost-effectiveness. By using CNC milling for prototyping, manufacturers can create high-quality prototypes that accurately represent the final product and improve the overall efficiency and profitability of their operations.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items