The competition in the machining industry is extremely fierce. Sometimes, the key lies in whether the machining task can be completed in a short time while ensuring quality. Brass, aluminum, and steel are common machining materials. But which material has a faster machining speed? In this article, we will compare these three materials and attempt to answer this question.

Properties of brass, aluminum, and steel

Brass is an alloy that contains copper and zinc, so it has good conductivity and thermal conductivity. In contrast, aluminum is a metallic element with light weight, high strength, and strong corrosion resistance. Steel is an alloy composed of carbon and iron, which has high strength and good wear resistance. From a comprehensive perspective, compared to aluminum, brass has slightly lower strength but better conductivity, thermal conductivity, and corrosion resistance; And steel has higher strength and wear resistance.

Brass vs Aluminum vs Steel:Comparison

Usually, the speed of machining depends on the hardness and characteristics of the material, as well as the machining equipment and process used. Among the three common materials, brass, aluminum and steel, we will compare the following three aspects

Comparison of raw material characteristics

Brass, aluminum, and steel are common metallic materials that have different physical and chemical properties, as detailed in the following comparison table:

| Characteristic | Brass | Aluminum | Steel |

|---|---|---|---|

| Density (g/cm³) | 8.4 – 8.7 | 2.7 | 7.8 – 8.0 |

| Melting Point (°C) | 900 – 940 | 660 | 1370 – 1530 |

| Thermal Conductivity (W/m·K) | 109 – 125 | 205 | 43 – 50 |

| Electrical Conductivity (MS/m) | 17 – 30 | 34 – 65 | 10 – 20 |

| Young’s Modulus (GPa) | 96 – 123 | 68 – 79 | 190 – 210 |

| Yield Strength (MPa) | 170 – 450 | 40 – 550 | 215 – 230 |

| Tensile Strength (MPa) | 300 – 600 | 70 – 700 | 400 – 550 |

| Hardness (Brinell HB) | 60 – 140 | 15 – 120 | 120 – 600 |

| Corrosion Resistance | Moderate to High | High | Low to Moderate |

| Magnetism | Non-magnetic | Non-magnetic | Magnetic |

| Flammability | Non-flammable | Non-flammable | Non-flammable |

| Alloying Elements | Mainly Copper and Zinc | – | Iron, Carbon, and other elements |

Brass is an alloy composed of copper and zinc, which is dense and has good corrosion resistance and electrical conductivity. Aluminum is a lightweight metal with a relatively low density, good thermal conductivity and corrosion resistance. Steel is an iron alloy rich in carbon, dense, rich in strength and durability.

Comparison of mahcining processes

Brass, aluminum, and steel have different machining techniques, which have an impact on their machining speed. Please continue reading on the machining processes and applicable processes of the three materials

brass

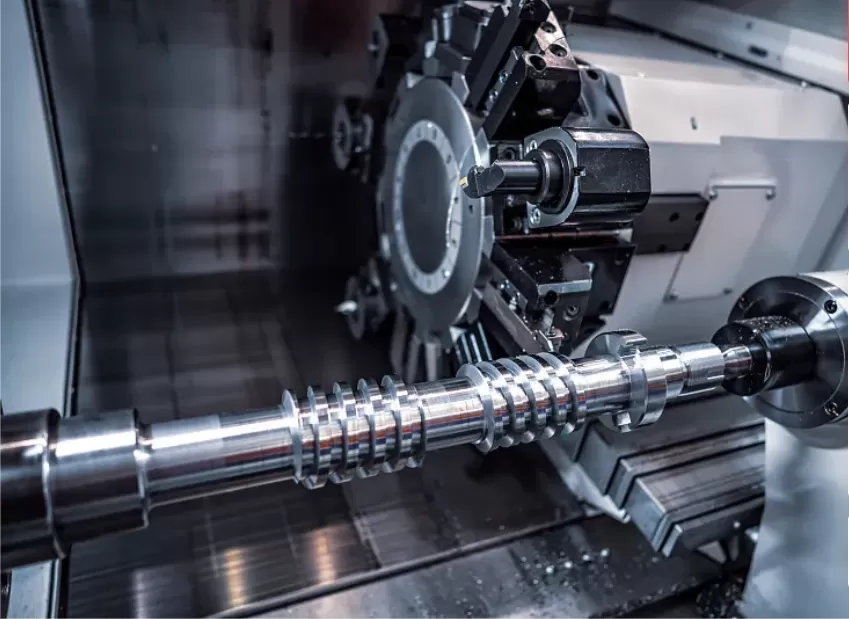

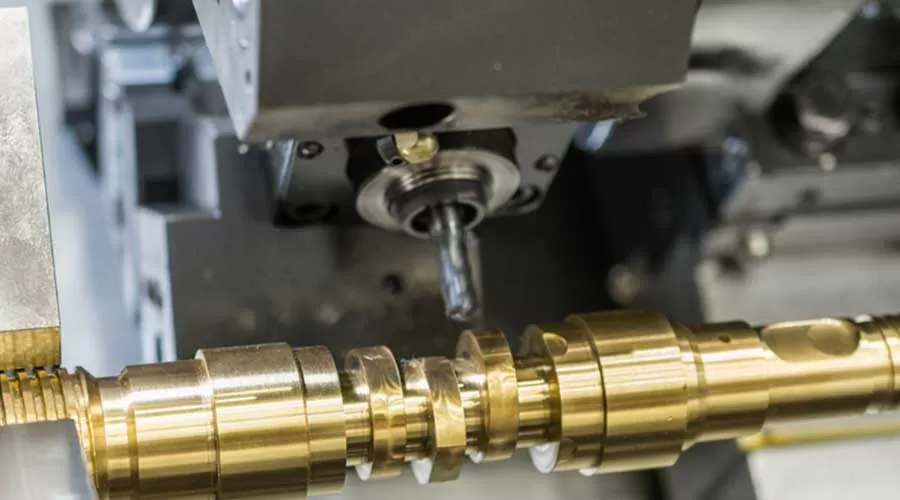

1.Cutting machining : Brass has good cutting performance and is suitable for machining with cutting tools, such as turning, milling, drilling, etc.

2.Stamping machining : Brass can be used to produce complex shaped parts through stamping processes, such as stamping, stretching, bending, etc.

3.Casting machining : Brass is suitable for die-casting or gravity casting processes to manufacture parts with complex shapes.

aluminium

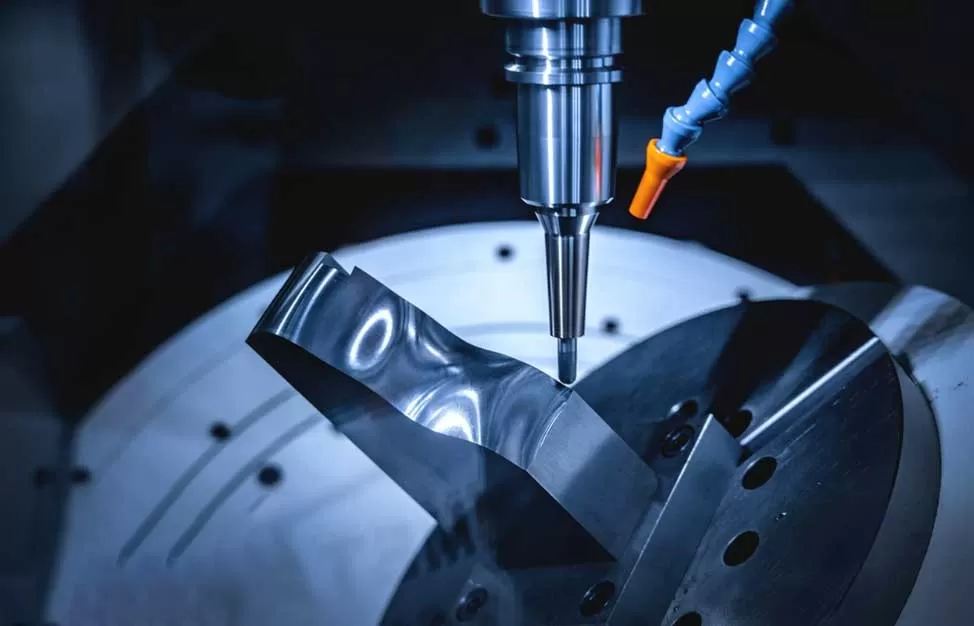

1.Cutting machining : Aluminum has good cutting performance and is suitable for high-speed cutting. Common machining methods include milling, turning, drilling, etc.

2.Die casting machining : Aluminum can be used to manufacture precision aluminum alloy parts through the die casting process, suitable for mass production.

3.Welding machining : Aluminum can be connected and assembled using welding processes such as TIG (tungsten argon arc welding) and MIG (metal inert gas welding).

steel

1.Cutting: The cutting of steel requires the use of high hardness cutting tools, and common cutting processes include milling, turning, drilling, etc.

2.Welding machining : steel can be connected and assembled by various welding processes such as Arc welding, gas shielded welding, Laser beam welding, etc.

3.Heat treatment: Steel often requires heat treatment, such as quenching and tempering, to adjust its hardness, strength, and toughness.

Comparison of machining speed

In actual production, the machcining speed of brass, aluminum, and steel is influenced by various factors, such as material hardness, material and shape of cutting tools, technology and level of machcining technology, etc. The following is a comparison of the machining speeds of the three materials in common machcining processes such as milling, turning, drilling, and stamping

| machining Method | Brass | Aluminum | Steel |

|---|---|---|---|

| Milling | 50 – 150 mm/s | 100 – 300 mm/s | 30 – 80 mm/s |

| Turning | 0.05 – 0.3 mm/rev | 0.1 – 0.6 mm/rev | 0.02 – 0.1 mm/rev |

| Drilling | 15 – 60 mm/min | 50 – 200 mm/min | 10 – 40 mm/min |

| Stamping | 80 – 300 strokes/min | 150 – 500 strokes/min | 40 – 120 strokes/min |

Under the same machcining conditions, brass has the fastest machcining speed among the three materials, followed by aluminum and steel. This is mainly because brass has lower hardness and indentation depth, making it easy to cut and mill

Factors affecting machining speed

The machining speed of brass, aluminum and steel is affected by a number of factors. Here are some of the main factors that affect their machining speed:

1.Material hardness

Material hardness will directly affect the machining speed. In general, harder materials require a slower cutting speed, while softer materials can adopt a higher cutting speed.

2.Cutting condition

Cutting parameters are directly related to the machining speed, including cutting speed, feed speed and cutting depth. Different materials require different cutting parameters to obtain the best machining results.

3.Tool selection

The choice of tool type and tool material suitable for the material will also affect the machining speed. Different materials may require different types and characteristics of the tool to achieve higher machining speed and cutting efficiency.

4.Tool selection

Choosing the tool type and tool material suitable for the material will directly affect the machining speed. Because different materials require different types and characteristics of the tool, in order to achieve more efficient machining speed and cutting efficiency.

5.Job design

The shape, size and complexity of the workpiece also affect the machining speed. More complex workpieces may take longer to process, while simple geometric shapes can be machined faster.

6.Machine tool performance

The rigidity, stability and power of the machine will also have an impact on the machining speed. High performance machine tools usually have higher cutting speeds and higher production efficiency.

conclusion

This article introduces the characteristics and machining speed of brass, aluminum, and steel, and proposes materials that can be processed relatively faster. Whether you are using these materials in your work or for a material research purpose, we hope this article can help you better understand these materials.

Brass, aluminum and steel machining applications in different industries

Brass, aluminum, and steel have a wide range of applications in machining . The following are common machining applications in some major industries:

1.brass

Manufacturing: Brass machining is used to manufacture precision parts, valves, fasteners, and connectors.

Electronics and electrical industry: Brass machining is used for manufacturing electronic sockets, switches, and connectors.

Instrument manufacturing: Brass machining is commonly used to make instruments such as trumpet, trombone, and brass organ.

2.aluminium

Aerospace industry: Aluminum machining is used in the aerospace industry to manufacture aircraft parts, spacecraft components, and equipment.

Automotive industry: Aluminum machining is used to manufacture automotive bodies, engine parts, and chassis components.

Packaging industry: Aluminum machining is used for making food and beverage cans, cosmetic packaging, and pharmaceutical packaging.

3.steel

Manufacturing: steel machining is used to manufacture various Machine element, tools, bearings and gears.

Architecture and Infrastructure: Steel machining is used in the manufacturing of structural components, bridges, and building components in the field of architecture and infrastructure.

Automotive industry: Steel machining is used to manufacture automotive components such as body frames, suspension systems, and steering components.

Starting brass, aluminum, and steel machining services now!

Are you at a stage where you need to build a new product? Or do you already have a design but need a lab to turn it into a producible prototype?

No matter what stage you are in, we can provide you with fast and reliable brass, aluminum and steel machining services.

We offer services from design to rapid prototyping – which means you just need to sit down with our designers and communicate your ideas before we turn them into real products.

No matter what style and specification of products you need, we can provide various customized services according to your requirements, including CNC milling, CNC turning, stamping, cutting and forming. Please contact us, we are happy to provide you with more detailed information.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com