Bronze CNC Machining

Bronze is a commonly used metal alloy suitable for manufacturing various types of CNC machining parts.we help manufacture products with complex geometries and high aesthetic demands.

- Manufacturing on demand

- Tolerances down to +/- 0.01mm

- Delivery in as little as 3 days

- All uploads are secure and confidential

Custom Bronze CNC Machining

Our bronze cnc machining services cover the entire production process from design to machining. We can carry out high-precision machining according to customer requirements, such as parts of various shapes, mechanical components of precise shapes, bronze parts of various materials, etc.

Our customers come from all over the world, including the United States, Europe, Asia and other places. We are customer-centric and always focus on customer needs and satisfaction.E-Mail: gloria.wu@longshengmfg.com

Our Manufacturing Capabilities

Longsheng has many years of experience in bronze CNC machining, and is the best choice for you to find high-quality bronze CNC machining services. We offer high precision bronze CNC milling and bronze CNC turning to provide reliable solutions for your bronze parts and products manufacturing.

CNC Milling machining

CNC milling is done by using a rotary cutter on a milling machine to cut the bronze material to achieve shape processing. CNC milling can precisely control the movement of the tool on the three coordinate axes, thus achieving the machining of complex shapes and the smoothness of the surface of the part.

CNC Turning machining

CNC turning is the shape machining of bronze material by cutting it using a tool on a lathe. CNC turning can realize the machining of various outer diameters, inner diameters, end faces and threads by rotating the workpiece and moving the tool on two or three coordinate axes.

Bronze part surface finishing options

1.Polishing:Polishing can improve the appearance and finish of bronze parts.

2.Sandblasting:Sandblasting can achieve uniform surface quality of bronze parts.

3.Anodizing:Anodizing provides corrosion resistance, wear resistance and color diversity.

4.Spraying:Spraying can change the color, texture and chemical properties of the surface of a bronze part.

5.Electroplating:Electroplating can improve appearance, wear resistance and corrosion resistance, providing a variety of metal options.

Mobile:+86 18566759667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com

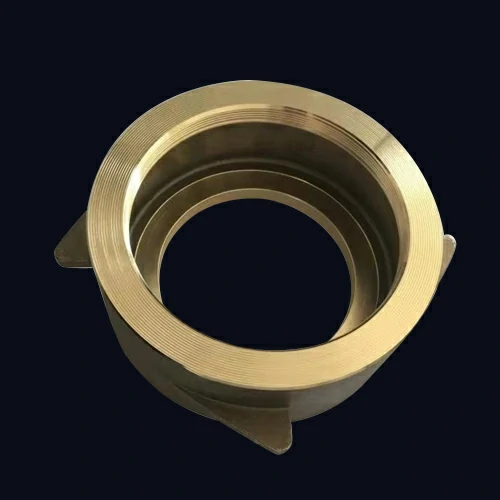

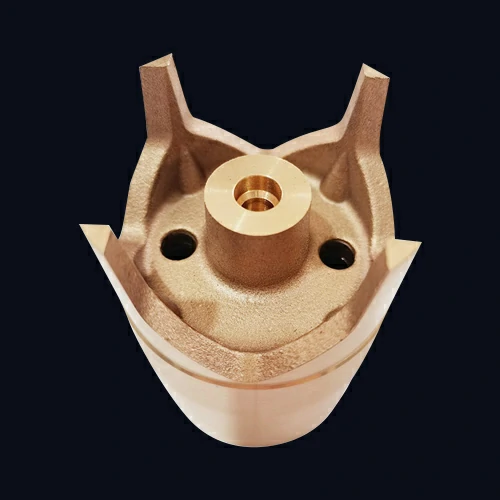

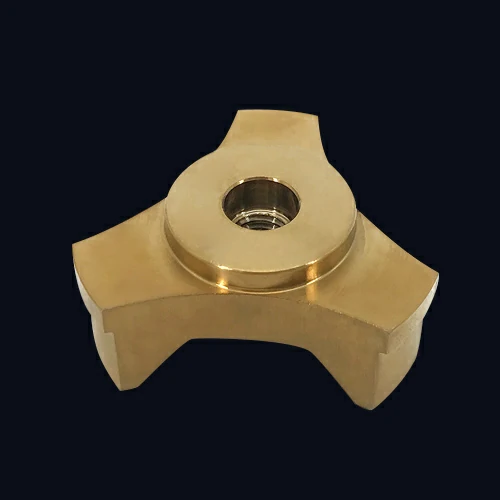

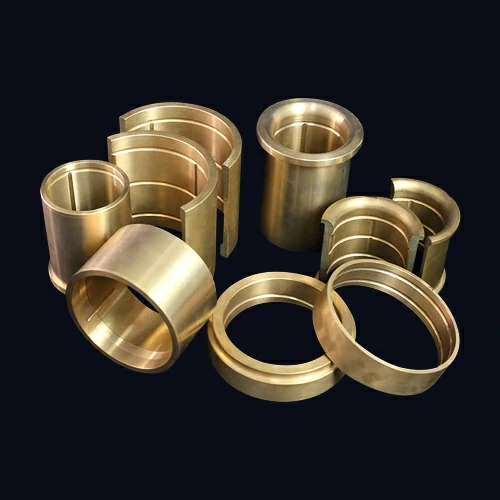

CNC Machining bronze Parts Picture

View the custom bronze parts we process for customers, from rapid prototyping, small batch production to batch production orders

Why Choose Us

Bronze parts manufacturing FAQ

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required bronze CNC machining services support by reading FAQ.

There are several important factors to consider when choosing a material produced using bronze CNC machining. These factors include the desired product shape and size, the required strength and precision level, and the use and environment in which it is used. Longsheng Technology supplies most industry standard materials, contact us for more information

Bronze machining time often depends on the complexity and number of machined parts. Some small bronze parts may only take a few minutes, while large or complex bronze parts may take up to several hours to process.

Not all bronze can be CNC machining. At Longsheng Technology, we particularly understand the characteristics of bronze materials and will choose the right materials and processing tools according to your specific needs to ensure the best results.

Latest Blog Posts