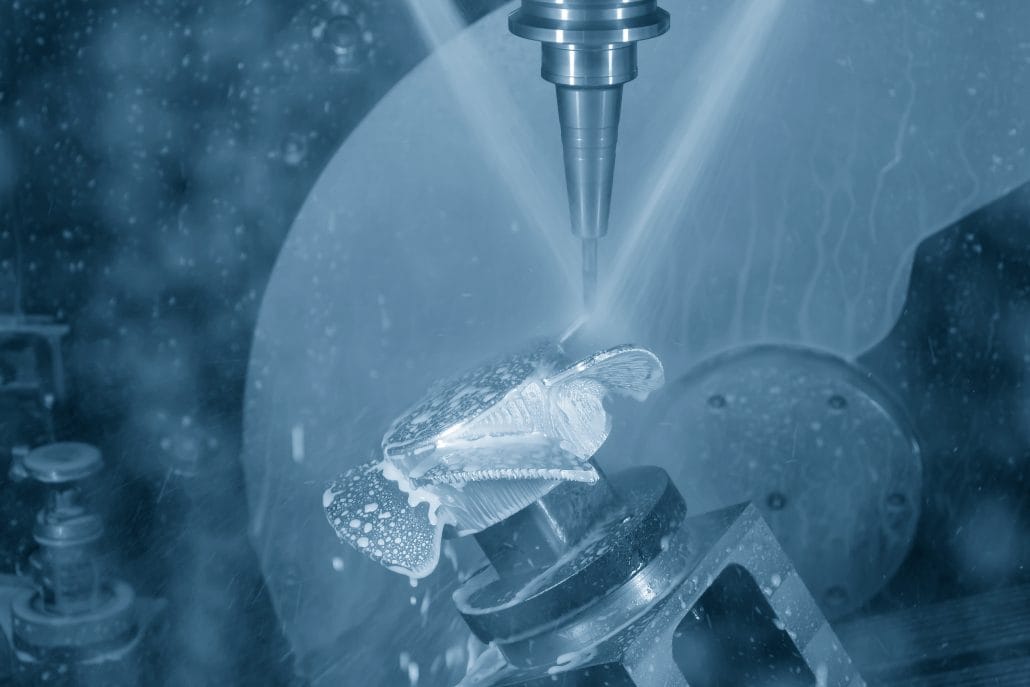

Have you ever encountered the problem of uneven, burr and uneven surface in the process of precision parts machining, and these problems lead to some parts unqualified, increasing the manufacturing cost and delivery cycle

This is because in the process of precision parts machining, parts in the cutting process, leading to the residual area caused by tool geometry and cutting motion, bonded on the cutting edge of the chip tumor in the groove, vibration between the workpiece and the tool caused by the vibration ripple and the tool surface wear caused by extrusion and friction marks and other reasons, so that the parts surface roughness. Therefore, how to control the surface roughness of precision parts has become one of the hot issues in the field of precision parts machining.

Cause of Surface Roughness Of Precision Parts

According to the experience of engineers, the reasons for the roughness of the surface of precision parts are as follows:

- The cutting rate is too slow

- Cutting parameters

- Pitch and cutting depth

- The machining track is too long

- Tool wear path

- Improper selection of machining materials

- Improper cutting fluid

- Overheat or undercold machining

- Manufacturing and use of cutting fluid

- Cutting Angle is not appropriate

- Vibration and temperature changes during machining

- Machine tool performance

The cutting rate is too slow

The cutting rate is too slow usually leads to the formation of grooves, extrusion marks and other roughness on the workpiece surface, which is due to the metal cutting force in the process of cutting resulting in large elastic deformation on the machined surface. When the cutting force accumulates to a certain degree within a certain time, the workpiece surface forms traces.

Cutting parameter

Cutting parameters are one of the main factors causing surface roughness of precision parts. Selection of inappropriate cutting conditions, improper tool use, poor treatment will lead to parts surface quality decline, thus affecting production efficiency and quality.

Pitch and cutting depth

In the process of parts machining, the size of pitch and cutting depth will also affect the quality of parts surface. If the pitch is too small or the cutting depth is too large, it will also cause slight burr or wear marks on the surface of the parts, thus affecting the quality and smoothness of the surface.

The machining path is too long

Too long machining trajectory will lead to obvious roughness of solar grain, cone or pyramid shape on the workpiece surface. The reason for the formation of this roughness is that in the machining process, in the cutting process of the tool, the place where the gap is large turns to high cutting force and thermal deformation effect, and eventually leads to the surface of the uneven phenomenon.

Tool wear degree

In the process of parts machining , tool wear degree will also affect the quality of parts surface finishing . If the tool is worn too much, then the cutting effect will become poor, resulting in slight burrs or wear marks, which will reduce the surface finish and smoothness of the part.

Improper selection of machining materials

The hardness, toughness and other properties of machining materials directly affect the formation of parts surface. If the material chosen is not suitable for the precision required for machining, surface roughness will result. Therefore, when selecting materials for machining , attention should be paid to the performance requirements of materials.

Improper cutting fluid

Improper cutting fluid will lead to an increase in surface roughness, especially when the material processed is sensitive to liquid, such as copper, titanium, tin, etc. In the process of procmachining essing should pay attention to the concentration of cutting fluid, PH value and a reasonable proportion of temperature, to avoid the cutting fluid concentration is too high, PH value is too high or too low factors.

Overheat or undercold machining

machining overheating or cooling will lead to the increase of surface roughness, the cooling effect of cutting fluid is not good, resulting in the increase of surface roughness.

Cutting fluid manufacturing and use problems

In the machining process, the manufacturing and use of cutting fluid is also a very important link. If the cutting fluid quality is not up to standard or improper use, then it will also affect the quality of the parts surface. For example, if the cutting fluid is too dense, the cutting fluid will not be sufficiently lubricated, resulting in a certain degree of wear marks, reducing the surface quality; Cutting fluid is too thin will penetrate into the surface of the parts, so that the surface of the whole part cracks and scratches, affecting the surface smoothness and finish indicators.

The cutting Angle is inappropriate

In the process of parts machining, too large or too small cutting Angle will affect the surface quality of parts. If the cutting Angle is too small, then the surface of the parts will generate too much heat, resulting in a decline in surface quality. On the contrary, if the cutting Angle is too large, it will affect the cutting effect of the tool, resulting in tooth shape, thereby reducing the quality of the surface of the parts.

Vibration and temperature changes during machining

The vibration and temperature changes in the machining process will lead to the irregular formation of the surface of the parts, resulting in surface roughness. Therefore, in the process of machining , vibration and temperature changes should be minimized to ensure the stability of machining .

Machine tool performance

Machine tool performance is also one of the important factors affecting the surface quality of parts. Noise, vibration, error and other problems will affect the performance of the machine tool, resulting in the decline of parts surface quality.

Method to solve surface roughness of precision parts

The reasons that affect the surface roughness of precision parts are described above. In this section, I will share some solutions. I hope the knowledge shared by Longsheng can help you

The solutions are mainly as follows:

- Improve cutting speed

- Adjust machining parameters

- Preparation before machining

- Optimize tools and fixtures

- Finish

- Choose the right materials

- Use the right lubricant

- Improve cutting fluid conditions

- Improve the process flow

- Reasonable design of workpiece clamping mode

- Strengthen quality testing

ncrease cutting speed

Cutting speed is one of the key parameters that affect the roughness of the machined surface. When the cutting speed is too low, the shear force between the tool and the workpiece will increase, resulting in uneven surface. And when the cutting speed is too high, the tool is easy to wear, or even cause falling off. Therefore, in the process of machining , should be based on the hardness of the material and the process of the situation, choose the appropriate cutting speed.

Adjust machining parameters

Machining parameters are important factors affecting surface roughness of precision parts during machining. In the process of machining, if the machining parameters are not reasonable, it is easy to lead to excessive surface roughness. Therefore, adjusting machining parameters can effectively control the surface roughness of parts. When adjusting the machining parameters, it is necessary to select according to different machining materials, machining methods and technological requirements.

Preparation before machining

Prior to machining , the workpiece needs to be prepared, such as cleaning and cleaning the surface of the workpiece. This can not only avoid the interference of residue quality to the machining process, but also ensure the cleanliness and finish of the parts surface, so as to reduce the occurrence of surface quality problems.

Optimize tools and fixtures

Tool and fixture are the other two important factors of surface roughness in precision parts machining. If the cutting tool and fixture design is not reasonable, it will easily cause excessive surface roughness. Therefore, the optimization of tool and fixture can effectively control the surface roughness of parts. The optimization of tool and fixture can be started from the machining tool shape, material, hardness, coating and other aspects.

Surface treatment

After finishing, the surface of the parts needs to be treated to reduce the surface roughness. This treatment includes grinding, grinding and other methods. For some special work pieces, you can also choose chemical treatment or electrochemical polishing methods.

Choose the right materials

In machining precision parts, the choice of materials is very important. If you choose a low quality material, it may result in more burrs and marks on the finished surface. When selecting materials, factors such as hardness, ductility and toughness should be taken into account in order to obtain better surface quality during machining .

Use the appropriate lubricant

Lubricants reduce heat and friction and help prevent roughness from forming on the surface of parts. We need to choose the appropriate lubricant according to the characteristics of machining materials and machining methods. In practice, we can appropriately increase the amount of lubricant, or increase the viscosity of lubricant, to improve the surface quality.

Improve cutting fluid conditions

Cutting fluid is an important material to maintain good communication between the tool and the workpiece, but also one of the important factors affecting the surface quality, the appropriate cutting fluid quality will directly determine the surface finish. Therefore, in the process of machining pay attention to the selection of cutting fluid, concentration, cleanliness and cycle filtration and other factors

Improved process flow

In the process of parts machining , we not only need to consider the selection of tools and materials, but also need to consider the improvement of the machining process, choose the most suitable machining method and machining sequence to reduce the roughness of parts surface.

Reasonable design of workpiece clamping mode

The workpiece clamping mode also has a certain influence on the roughness of the workpiece surface. We need according to the characteristics of the machining object, reasonable choice of workpiece clamping way. In practice, the surface roughness can be reduced by pneumatic clamping.

Strengthen quality inspection

In the process of machining , strengthening the detection of product quality is an important guarantee to ensure the surface quality of precision parts. Only through strict quality detection, can we find and solve the problem of rough machining surface in time. Therefore, manufacturing enterprises should establish a perfect quality inspection process, from raw materials into the factory to products out of the factory, should go through strict quality control.

Controlling surface roughness of precision parts is the key to quality control of precision parts machining, which requires a comprehensive machining quality control scheme. Here introduced some of the formation of roughness reasons and solutions, I believe that the majority of users will be helpful.