In mechanical processing, milling is crucial for metalworking. This guide explores climb milling (down milling) and conventional milling (up milling), focusing on their impact on precision CNC machining parts.

What Is Climb Milling?

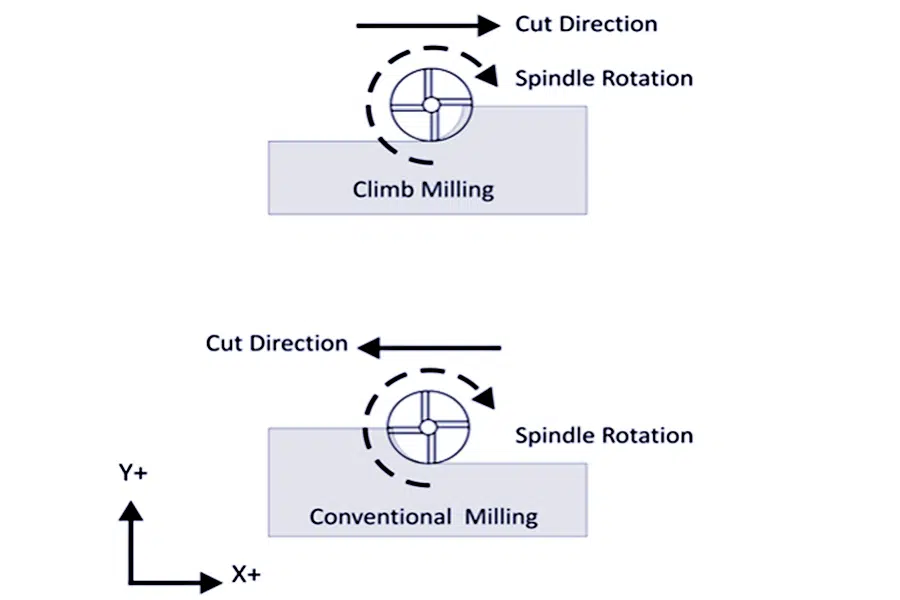

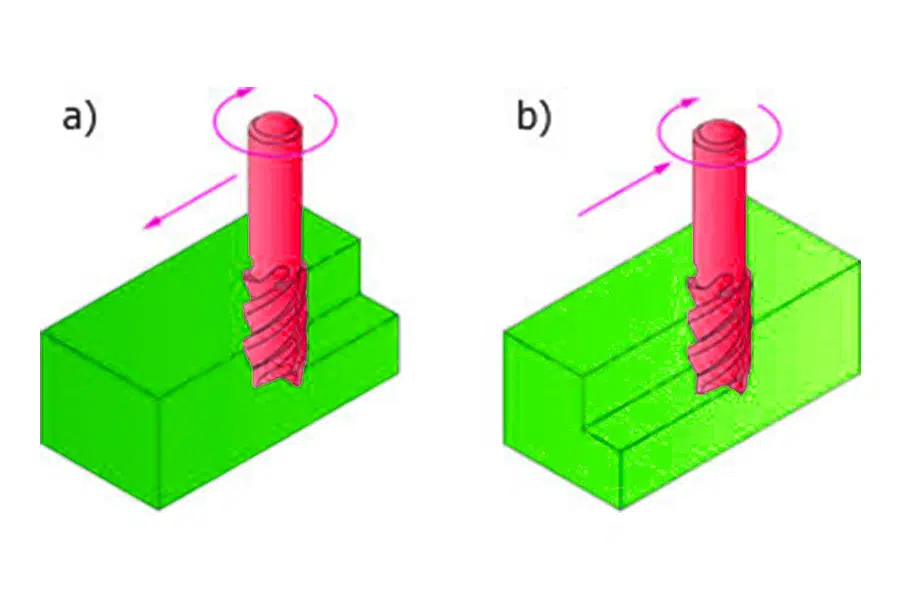

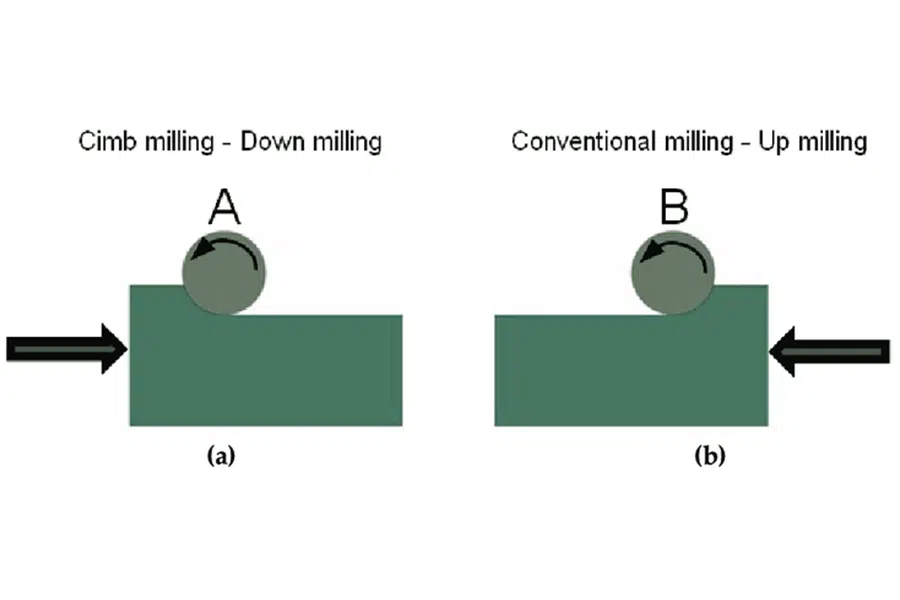

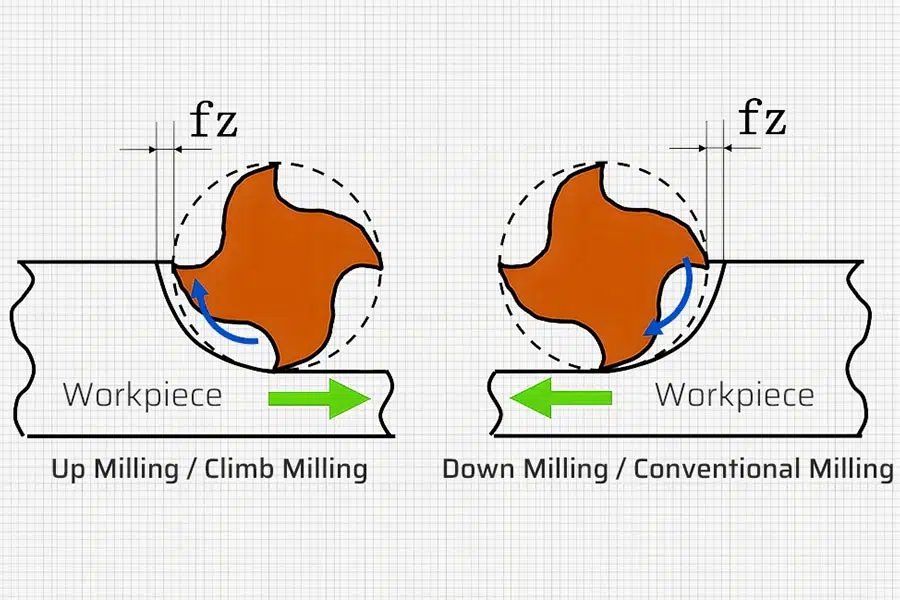

Climb milling involves the cutter and workpiece moving in the same direction, starting with thick chips that thin out. This improves surface finish and tool life but requires stable setups, especially in a high precision CNC machining environment.

Mechanics of Climb Milling

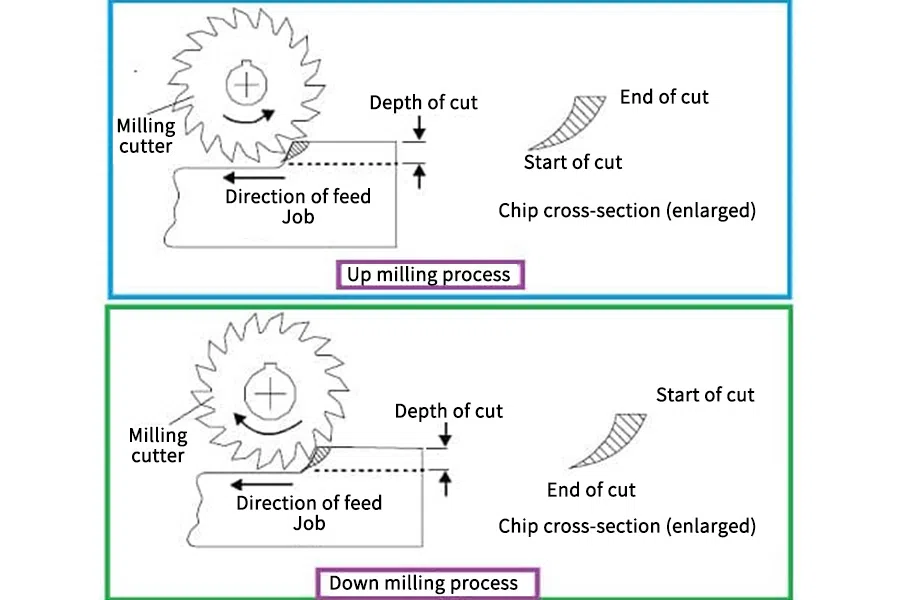

The cutter rotation aligns with feed direction, enhancing speed and reducing deflection, ensuring smoother surfaces. The chip thickness starts thick and thins out, helping in heat reduction and efficient chip ejection, which is crucial in multi-axis CNC machining.

Features of Climb Milling

- Chip Thickness: Starts from zero, gradually increasing.

- Advantages:

- High processing accuracy.

- Good surface quality.

- Low tool wear.

- Suitable for deformable materials.

- Improved efficiency on CNC machines.

- Disadvantages:

- Requires strong clamping force.

- Risk of roughing on hard layers.

- High performance requirements for machine tools.

- Not suitable for all materials.

What Is Conventional Milling?

Conventional milling has the cutter rotating against the workpiece movement. The chip thickness increases from zero, creating more friction and heat.

Mechanics of Conventional Milling The cutting edge begins with zero thickness, increasing to maximum, causing potential heat and tool wear. This method tends to lift the workpiece, needing strong work holding.

Features of Conventional Milling

- Chip Thickness: Decreases from thick to thin.

- Advantages:

- Suitable for rough surfaces.

- Preferred for hard materials.

- Disadvantages:

- Generates more heat and tool wear.

- Rougher surface finish.

Comparison

- Cutting Force: Climb milling reduces force over time; conventional increases it.

- Chip Direction: Climb leaves chips behind; conventional leaves them ahead.

- Friction & Heat: Higher in conventional.

- Tool Life: Longer in climb milling.

- Surface Finish: Smoother in climb milling.

Applications

- Rough Machining: Conventional preferred for high cutting volume and uneven surfaces.

- Finishing: Climb milling for high precision and smooth surfaces.

Common Materials for CNC Milling

- Aluminum CNC Machining: Lightweight, high strength, good for various applications.

- Steel: High formability and weldability.

- Copper: Excellent electrical conductivity.

- CNC Titanium Machining: Strong, light, and corrosion-resistant.

- CNC Plastic Machining: Diverse and cost-effective.

- Ceramics: High strength and wear resistance.

Choosing the Right CNC Machining Parts Factory

Selecting the right CNC machining parts factory involves considering their expertise in both climb and conventional milling, especially in multi-axis CNC machining. A factory skilled in high precision CNC machining ensures superior surface finish and dimensional accuracy.

Conclusion

Choosing between climb milling and conventional milling depends on specific machining requirements, materials, and desired precision. Climb milling excels in high-precision tasks, while conventional milling is suitable for rough machining and hard materials. For optimal results, partnering with a proficient CNC machining parts factory that specializes in multi-axis CNC machining and high precision CNC machining is crucial.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

This design is wicked! You most certainly know how to keep a reader amused.

Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Great job.

I really loved what you had to say, and more than that,

how you presented it. Too cool!

What’s up, after reading this amazing post i am as well delighted to share my know-how here

with mates.

Thank you for sharing superb informations. Your website is so cool. I am impressed by the details that you have on this site. It reveals how nicely you understand this subject. Bookmarked this web page, will come back for extra articles. You, my friend, ROCK! I found just the information I already searched all over the place and simply couldn’t come across. What an ideal website.

I am extremely inspired with your writing talents and also with the format for your blog. Is that this a paid theme or did you customize it yourself? Either way keep up the excellent quality writing, it is uncommon to look a nice weblog like this one today!

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.