CNC machining is a manufacturing process that involves the use of computers to control machining tools. Aerospace parts, which require high precision and accuracy, are often made using CNC machining. This process has revolutionized the manufacturing of aerospace parts, which are known for their complex geometries and tight tolerances.

As a CNC machining aerospace parts manufacturer, we specialize in producing high-quality parts for the aerospace industry. Our state-of-the-art facility is equipped with the latest CNC machines and technology, allowing us to manufacture parts with extreme precision and accuracy. We have a team of skilled machinists and engineers who are experienced in working with various materials, including aluminum, titanium, and stainless steel. Our team is dedicated to providing our clients with the best possible solutions for their aerospace part manufacturing needs.

What Is Aerospace CNC Machining?

CNC machining for the aerospace sector produces precision components, assemblies, and kits through processes like CNC milling and CNC turning for applications in space shuttle and aircraft assembly, maintenance, and repair. Compared to conventional CNC machining, aerospace CNC machining requires tighter tolerances and typically involves harder-to-machine materials. Manufacturers for the aerospace sector use high-value machining equipment such as turn-mill and five-axis machines and precision grinders to produce components like hinges, bushings, and clamps, as well as custom parts.

Most Generally Used CNC Machining Gear Within The Aerospace Trade

| Gear Kind | Description | Utility | Significance |

|---|---|---|---|

| CNC Lathes and Turning Machines | Machines that rotate supplies to create inside and exterior options like holes, bores, and threads. | Used for parts which are symmetrical round an axis, resembling shafts and propellers. | Important for producing axially symmetric parts. |

| CNC Milling Machines | Identified for rotating slicing instruments whereas the fabric is stationary, producing varied shapes. | Manufacturing of plane elements resembling fuselage, wings, engine parts, and cockpit elements. | Key tools for advanced 3D parts, particularly 5-axis milling machines for advanced elements. |

| CNC Laser Machines | Make the most of a targeted laser beam for slicing, slicing, or engraving supplies. | Half marking and ornament of machined elements. | Not as widespread as milling machines and lathes however necessary for particular functions. |

| CNC Electrical Discharge Machines (EDM) | Use managed electrical sparks to form supplies, creating micro holes, slots, and angled options. | Creating exact and complicated elements that require micro options. | Specialised functions inside aerospace manufacturing. |

| CNC Plasma Cutting Machines | Make use of a computer-controlled plasma torch to chop conductive supplies. | Cutting steel, stainless steel, and aluminum parts for aerospace constructions. | Helpful for slicing thick supplies shortly and exactly. |

Within the aerospace business, CNC machining’s versatility and precision make it a beneficial asset within the producer’s toolkit. CNC lathes and turning machines are important for producing axially symmetric parts. CNC milling machines are the important thing tools for advanced 3D parts, with 5-axis milling machines being significantly helpful for advanced plane elements. CNC laser machines, whereas not as widespread, play a task partly marking and ornament. CNC EDMs are used for creating exact micro options, and CNC plasma slicing machines are helpful for slicing conductive supplies shortly and exactly. These machines’ exact management and environment friendly manufacturing capabilities allow the aerospace business to supply high-quality parts that meet strict requirements and complicated designs.

Materials for Aerospace Machined Parts

The aerospace industry has strict regulations for acceptable materials in parts manufacturing. They must be strong and durable yet lightweight. Aluminum is one of the most common materials fulfilling these conditions for aerospace CNC machining, either as an alloy or in its pure form. Compliant materials for aerospace parts include:

- Aluminum Alloy Series 2xxx. Combined with copper, this high-strength aluminum alloy series possesses good workability and superior machinability. It has common applications in machined parts such as fuselage structures and airplane wings for its impressive strength-to-weight ratio.

- Aluminum Alloy Series 6xxx. One of the most versatile aluminum alloy series, this material alloys aluminum with magnesium and silicon, enhancing its corrosion resistance, strength, and formability.

- Aluminum Alloy Series 7xxx. This aluminum series is composed of zinc—which is the primary alloying element—magnesium, chromium, and copper. Its alloys display impressive strength for applications throughout the aviation and defense industries for military aircraft.

Applications Of cNC machining in aerospace manufacturing

1.lightweight metal components

The components dominate the aerospace industry because they are relatively lightweight than steel or other metals. This makes them ideal for fuel economy and overall performance. In addition, it allows for the seamless fabrication of these metals by providing compatibility with various materials.

2.complex design fabrication

Advanced manufacturing methods have been developed to meet the demands of aeronautical design. These include 5-axis CNC milling machines, which can deliver reaches and angles that might not be feasible using 3- or 4-axis machines.

3.CNC Rapid Prototyping

It is a process that allows 3D CAD modeling to be used as the basis for manufacturing parts. In addition, aerospace engineers can use this method to develop new prototypes and test/edit them in real-time. This method minimizes expenses by not having to invest in tooling or comply with regulatory requirements, such as AS9001 and ISO 9001:2015 standards.

4.AI-Aided CNC machining

The aerospace industry is a complex one. It is filled with many components, materials, and processes that require accuracy to function correctly. For example, one such method can be affected by inaccurate data in machining parts for aircraft. The result is a more efficient manufacturing process that improves productivity and yields higher profits for all involved.

5.high-grade precision

Precision CNC machining is a game-changer for aerospace companies. It allows them to manufacture components meticulously as specified and deliver tolerances as small as 4μm. In an industry where part failure while in flight is not an option, CNC machining renders unparalleled precision.

problems during aerospace cNC machining

- When it comes to aerospace manufacturing, a mixed production line is an issue. The degree of specialization and integration is low, meaning there’s a great deal of cross-production. This makes it hard to improve efficiency.

- In the CNC machining process, program adjustment, fixture preparation, tool preparation, parts detection, and cutting efficiency take up more time. This causes a reduction in machining efficiency.

- Furthermore, the informatization level is still low—this limits the efficient operation of production and research.

- Deformation control of large structures is a problem because it can change the look of your system and make it difficult to maintain.

- And most importantly, the development cost and risk are high.

few tips of the cNC machining for the aerospace industry

- ivide the manufacturing system into specialized lines based on product characteristics and types. This helps streamline part production as you find the right machinery for the job at hand.

- Design your fixture correctly and shorten the preparation time of workpieces, improving efficiency and reliability.

- Expand your equipment scale with large high-speed mills specifically designed for this work.

- Implement information management practices so that all parts are accurately identified, organized, and traced back to their source material.

- Use CNC machining simulation technology to ensure everything is done correctly from start to finish!

The future of cNC machining in aerospace

| AVIATION | IN SEARCH OF THE NEXT FRONTIER: SPACE TRAVEL |

|---|---|

| It is a fascinating industry that requires an incredible amount of accuracy. Whether it’s the innermost layer or outer shell of an aircraft, every part must be precise for it to be used as intended. For example, the engine is the most crucial component in an airplane for exterior operation. The cockpit of a car is where you are most likely to find yourself, and when it comes to interior design, CNC machining aerospace parts plays a pivotal role in designing the cockpit. For example, some of the tiniest interlinked details make up the real-time navigational system that provides directions to pilots. In addition, CNC machined parts boast extreme precision and significant endurance to rule out any odds of failure. | NASA and SpaceX are two of the most successful organizations in the world, and their work is central to our understanding of space travel. Their spacecraft is designed with the highest levels of technology and craftsmanship. To build the best rocket ships, NASA and SpaceX use CNC machining to manufacture tiny parts that tether the rocket’s body design. These parts must operate without fail and prioritize the safety of the spacecraft and its crew members. You must choose an appropriate CNC lathe for your machining shop to prevent inaccuracies and deliver best-in-the-business components. |

about long sheng aerospace CNC machining service

Why Choose Us for Aerospace Manufacturing

We understand that the aerospace industry has extremely high requirements for the reliability and quality of parts, so we strictly adhere to quality standards to ensure that the produced parts meet industry performance and safety standards. Whether you are developing new aircraft components or need to update and improve existing parts, Longsheng has the ability to meet your needs.

| Quick Quotation | ISO Certification | On Demand Custom | Fast Delivery |

|---|---|---|---|

| By uploading your CAD files, you can easily obtain quotes for aerospace parts within 2 hours and start the order process. Our efficient order tracking and management system keeps you updated on the latest status of orders to ensure that your project is progressing as planned. | As an ISO 9001 certified Chinese manufacturing company, our professional team is committed to ensuring that every aerospace component meets your required dimensional specifications, structural strength, and high-precision tolerances to meet strict quality requirements. | We understand that each aerospace project is unique, so our manufacturing process can be customized according to your specifications, requirements, and schedule. We can process aerospace parts with tolerances up to+/-0.005mm. | At Longsheng, you can obtain parts quotes in just 2 hours and the required aerospace parts in just 3 days. This enables you to shorten the project cycle time by up to 30%. |

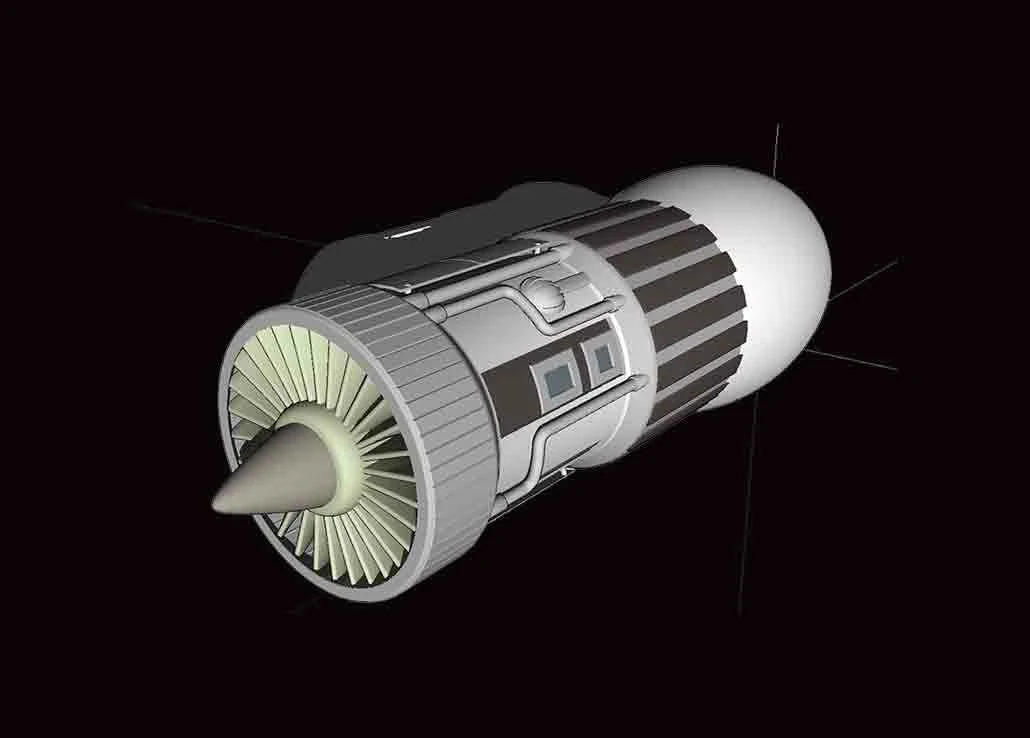

CNC Machining Aerospace Turbo Engine Prototype Parts Example

Longsheng provides rapid prototype design and manufacturing for high-end complex aerospace engines with high tolerance requirements, ensuring that every part accurately meets tolerance and specification requirements. Whether you need prototype design or mass production, our proud 5-axis CNC machining technology enables us to create outstanding turbine engine parts that meet the needs of all industries.

Surface Finishing for Aerospace Parts

Surface finishing for aerospace parts are available in many materials and colors. Whether you want to protect your parts from corrosion, enhance their appearance, or add texture, there is a surface finish that will meet your needs.

| Name | Description | Material | Color | Texture |

|---|---|---|---|---|

| Anodizing | Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

| Powder Coating | Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

| Polishing | The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

| Bead blasting | Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called “beads” or “media,” at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | / | Grainy, slightly matte texture |

| As machining | Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | / | Smooth, glossy finish |

conclution

Long Sheng Company specializes in the precision machining of aerospace parts and components that are essential to the maintenance and operation of aircraft and space shuttles. The integrity of these parts is vital. A fault in any component can be a huge safety and financial hazard. Aerospace manufacturers reduce risk by designing parts with extremely specific specifications and tight tolerances to ensure their proper function.

We understand that the aerospace industry demands the highest level of quality and safety. That’s why we adhere to strict quality control standards to ensure that each part meets the specifications and requirements of our clients. We use advanced inspection equipment to ensure that all parts are inspected and verified before they are shipped to our clients.

Whether you need parts for commercial or military aircraft, satellites, or space vehicles, we can provide you with reliable and cost-effective solutions. Our expertise and experience in CNC metal parts machining enable us to produce parts with tight tolerances, complex geometries, and high surface finishes. We work closely with our clients to understand their specific needs and requirements to provide tailor-made solutions that meet their unique needs.

With our aerospace CNC machining services, we can exceed these requirements, ensuring that the aerospace components that we machine pass industry standards. Additionally, as an ISO 9001-certified company, we adhere to strict guidelines to ensure our customers’ parts and data are properly handled and secure.

Contact us to learn about our Aerospace machining capabilities and to request a quote.

fAQs

How does CNC machining compare to other manufacturing methods for aerospace components?

The effectiveness of any manufacturing method is dependent on its application. Generally, CNC machining for aircraft components is one of the top manufacturing methods. However, organizations must pick the right CNC machining aerospace parts supplier to realize its benefits.

How can CNC machining be used to create complex geometries and shapes for aerospace components?

CNC machines are highly sophisticated, can reach tight tolerance, and can articulate various directions to manufacture complex components. The capability to take on complicated components quickly and reliably is essentially why many clients seek out a reputable CNC machining aerospace parts manufacturer.

How does CNC machining cope with aerospace components’ high temperature and pressure requirements?

CNC machining processes and programs can be adjusted to compensate for challenging materials, pressures, and temperatures. The versatility of this type of manufacturing is primarily why CNC machining has become so popular in aerospace.

How does CNC machining comply with aerospace industry standards and certifications?

CNC machining provides the means to achieve industry standards; in some cases, processes will need to be certified to a standard. Aerospace is a tightly regulated industry, so working with a manufacturing partner that understands these regulations and has all the necessary certifications is essential.