This article explores the advantages of two popular manufacturing techniques: CNC machining and EDM. Both methods have their own unique benefits that make them ideal for different applications. By understanding the advantages of each method, manufacturers can select the appropriate manufacturing technique to produce high-quality parts efficiently and cost-effectively.

CNC machining and EDM are two widely used manufacturing techniques that have their own unique advantages. When deciding which method to use, it is important to consider the material being machined, the required precision and accuracy, and the desired production volume. By selecting the appropriate manufacturing technique, manufacturers can produce high-quality parts efficiently and cost-effectively.

Difference between CNC machining and EDM

CNC machining and EDM (Electrical Discharge Machining) are two different techniques used for the manufacturing of parts in various industries.

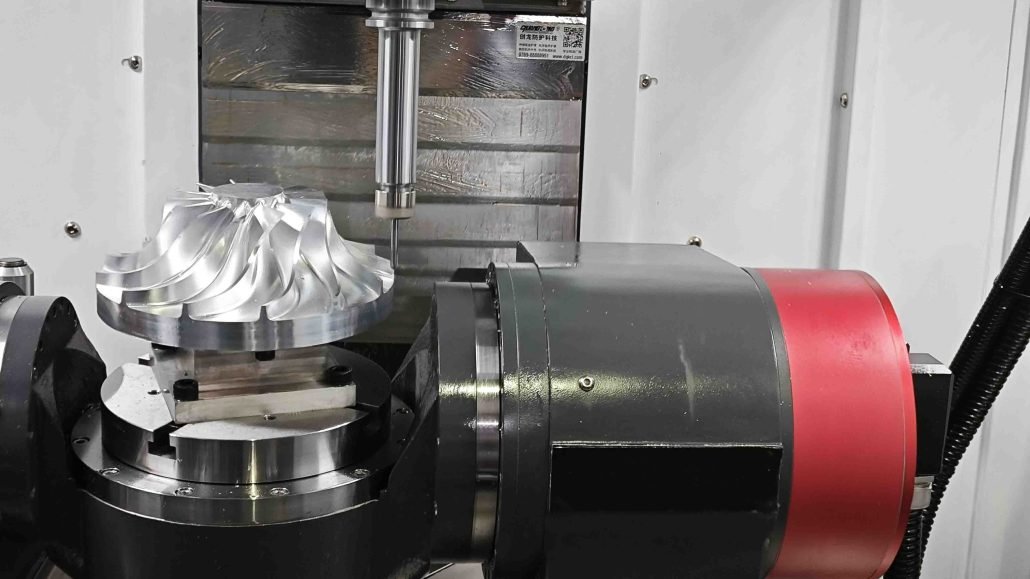

CNC Machining: It is a subtractive manufacturing process that involves the use of computer-controlled machines to remove material from a solid block of material to create a finished part. The process involves the use of cutting tools, which are guided by software programs to create the required shape and size of the part. CNC machining is widely used for the production of complex parts with high accuracy and repeatability.

EDM: It is a non-traditional manufacturing process that uses electrical energy to erode the material from a workpiece. EDM machines use a charged electrode wire or a shaped electrode to create an electrical spark between the electrode and the workpiece. The spark generates heat, which melts the material, and the molten material is removed by a dielectric fluid. EDM is mainly used for the production of complex parts with intricate shapes, and it is particularly useful for parts made of hard materials like titanium, tungsten, and hardened steels.

In summary, CNC machining is a subtractive manufacturing process that involves the removal of material to create a part, while EDM is a non-traditional manufacturing process that uses electrical energy to erode the material from a workpiece.

CNC Machining and EDM Advantages

CNC (Computer Numerical Control) machining and EDM (Electrical Discharge Machining) are two widely used methods in the manufacturing industry. Both of these techniques have their own unique advantages that make them ideal for different applications.

CNC Machining Advantages

CNC machining has become a popular manufacturing technique in recent years. It is widely used across industries and is capable of producing parts with high precision and accuracy. Here are some of the advantages of CNC machining:

- Precision: CNC machines can produce highly precise and accurate parts with tight tolerances. This is because the machines are controlled by a computer program, which ensures that the parts are produced to exact specifications.

- Flexibility: CNC machines are highly flexible and can be programmed to produce a wide range of parts with different shapes, sizes, and complexities. This means that manufacturers can use CNC machining to produce parts that are not possible with traditional machining techniques.

- Repetition: CNC machines can produce multiple identical parts with consistent quality. This is because the machines are programmed to produce the same part over and over again, ensuring that each part is identical.

- Speed: CNC machines are capable of producing parts at high speeds, reducing production time and increasing output. This is because the machines are automated and do not require manual intervention.

- Cost-effective: CNC machines are cost-effective for high volume production runs and can save time and money compared to manual machining. This is because the machines can produce parts quickly and accurately, reducing the need for manual labor.

EDM Advantages

EDM is another popular manufacturing technique that is widely used across industries. It is particularly useful for cutting hard materials that are difficult to machine with traditional methods. Here are some of the advantages of EDM:

- Hard materials: EDM is ideal for cutting hard materials that are difficult to machine with traditional methods. This includes materials such as titanium, tungsten, and hardened steel.

- No tool wear: EDM uses electrical discharge to cut materials, which means there is no physical contact between the tool and the workpiece, resulting in no tool wear. This means that the tool lasts longer and does not need to be replaced as frequently.

- Intricate shapes: EDM can produce highly intricate and complex shapes with high precision and accuracy. This is because the process uses an electrode to cut the material, which can be shaped to produce complex geometries.

- No burrs: EDM produces parts with no burrs, which means less finishing work is required. This is because the process does not produce chips or shavings, which can leave burrs on the part.

- Unique materials: EDM is capable of cutting a wide range of materials, including exotic alloys, composites, and ceramics. This means that manufacturers can use EDM to produce parts that are not possible with traditional machining techniques.

In conclusion, both CNC machining and EDM have their own unique advantages that make them ideal for different applications. When deciding which method to use, it is important to consider the material being machined, the required precision and accuracy, and the desired production volume. By selecting the appropriate manufacturing technique, manufacturers can produce high-quality parts efficiently and cost-effectively.

CNC Machining and EDM Processes

CNC machining and EDM (electrical discharge machining) are two common manufacturing processes used in the production of metal parts. CNC machining involves the use of computer-controlled machines to cut and shape metal parts to precise specifications. EDM, on the other hand, is a non-traditional manufacturing process that uses electrical current to erode metal and create complex shapes.

CNC machining is a versatile process that can be used to create a wide range of metal parts. The process involves the use of a computer-controlled machine that can move a cutting tool along multiple axes to create complex shapes. The process is highly accurate and can be used to create parts with tight tolerances. CNC machining is also a relatively fast process, making it ideal for high-volume production runs.

EDM, on the other hand, is a non-traditional manufacturing process that is used to create intricate shapes that would be difficult or impossible to create using traditional machining techniques. The process involves the use of an electrode that is charged with electrical current to erode metal and create the desired shape. EDM is particularly useful for creating parts with complex shapes, such as turbine blades, and for creating small or fragile parts that would be difficult to machine using traditional techniques.

In conclusion, both CNC machining and EDM are important manufacturing processes used in the production of metal parts. CNC machining is a versatile and accurate process that is ideal for high-volume production runs, while EDM is a non-traditional process that excels at creating complex shapes and small, fragile parts. By understanding the strengths and weaknesses of each process, manufacturers can choose the best process for their specific needs.

CNC Machining and EDM Applications

CNC machining is a manufacturing process that uses pre-programmed computer software to control the movement of machines and tools. This technology is widely used in the manufacturing of components for various industries such as aerospace, automotive, medical, and more. CNC machining offers a high level of accuracy and repeatability, making it ideal for producing complex components with precise dimensions.

EDM is a manufacturing process that uses electrical discharges to remove material from a workpiece. This technology is widely used in the manufacturing of components for various industries such as aerospace, medical, and more. EDM is particularly useful for machining complex shapes and hard materials that are difficult to machine using conventional methods.

In conclusion, both precision CNC machining and EDM are essential technologies in modern manufacturing. While CNC machining is ideal for producing components with precise dimensions, EDM is particularly useful for machining complex shapes and hard materials. Understanding the advantages of each technology is important for choosing the right manufacturing process for a particular application.

FAQ

CNC machining is a manufacturing technique that uses computer-controlled machines to produce parts with high precision and accuracy. The machines are programmed to produce parts to exact specifications, ensuring that each part is identical.

EDM is a manufacturing technique that uses electrical discharge to cut materials. The process does not involve physical contact between the tool and the workpiece, resulting in no tool wear.

Manufacturers should consider the specific needs of their project when choosing between CNC machining and EDM. CNC machining is ideal for high-volume production runs, while EDM is better suited for creating complex shapes and small, fragile parts.