CNC machining and extrusion molding are two popular manufacturing technologies used in rapid manufacturing. Both technologies offer a range of advantages for producing functional prototypes, tooling, and end-use parts. In this article, we will explore the characteristics of CNC machining and extrusion molding, and how they can benefit your manufacturing process.

CNC Machining

CNC machining is a versatile technology that uses computer-controlled machines to produce parts from a variety of materials, including metals, plastics, and composites. CNC machining offers a range of advantages, including high precision, speed, versatility, and cost-effectiveness. CNC machines are capable of producing parts with extremely tight tolerances, making them ideal for rapid manufacturing. The precision of CNC machining makes it possible to create complex parts with intricate details that would be difficult or impossible to produce with other manufacturing technologies. CNC machining is also known for its speed and versatility, making it possible to produce parts quickly and efficiently.

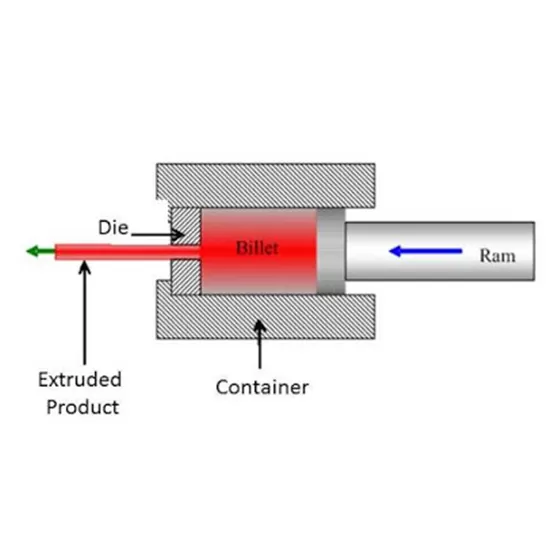

Extrusion Molding

Extrusion molding is a process that involves pushing material through a die to create a specific shape. This technology is commonly used for producing plastic parts. Extrusion molding offers a range of advantages, including high speed, low cost, and the ability to produce large quantities of parts quickly. Extrusion molding is ideal for producing parts that require high precision and strength, such as enclosures, brackets, and chassis. Extrusion molding is also known for its versatility, making it possible to produce parts in a wide range of shapes and sizes.

CNC Machining vs. Extrusion Molding

CNC machining and extrusion molding offer different benefits and are suited for different applications. CNC machining is ideal for producing parts with complex geometries and tight tolerances. It is also ideal for producing parts in low to medium volume production runs. Extrusion molding, on the other hand, is ideal for producing large quantities of parts quickly and cost-effectively. It is also ideal for producing parts with consistent wall thickness and uniform cross-sections.

Conclusion

In conclusion, CNC machining and extrusion molding are two popular technologies used in rapid manufacturing. Both technologies offer a range of advantages, and the choice between them depends on the specific requirements of your project. CNC machining is ideal for producing parts with complex geometries and tight tolerances, while extrusion molding is ideal for producing large quantities of parts quickly and cost-effectively. By understanding the characteristics of each technology, you can choose the one that best suits your needs and achieve maximum efficiency in your manufacturing process.