CNC (Computer Numerical Control) machining and sheet metal fabrication are two manufacturing processes that are commonly used in the industry. Both processes are known for their precision and efficiency in producing high-quality parts and components for various applications.

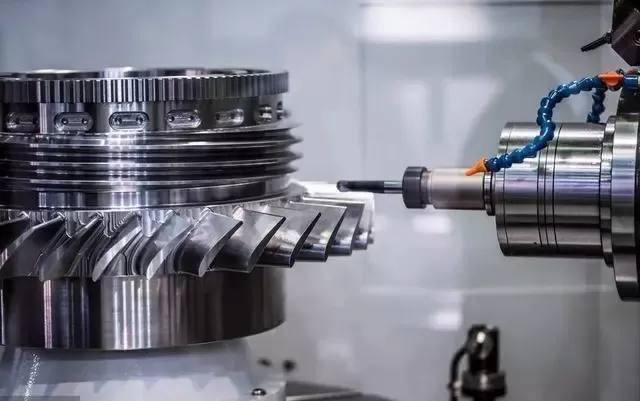

CNC machining involves the use of computer-controlled machines to remove material from a workpiece to create a desired shape or design. This process is widely used in the production of metal and plastic parts for different industries such as aerospace, automotive, and medical devices. CNC machines can perform a variety of operations such as drilling, milling, turning, and grinding, among others. The use of CNC machines ensures accuracy, repeatability, and speed in the production process.

On the other hand, sheet metal fabrication is a process that involves cutting, bending, and shaping thin metal sheets to create a specific product. This process is commonly used in the production of metal enclosures, brackets, and panels for various applications. Sheet metal fabrication can be done manually or using automated machines such as laser cutters, press brakes, and stamping machines. The use of automated machines ensures precision and speed in the production process.

Both CNC machining and sheet metal fabrication have their advantages and disadvantages. CNC machining is ideal for producing complex parts with tight tolerances, while sheet metal fabrication is ideal for producing large volumes of simple parts. CNC machining can be costly and time-consuming, while sheet metal fabrication is relatively cheap and fast. Choosing the right manufacturing process depends on the specific requirements of the application.

In conclusion, CNC machining and sheet metal fabrication are two important manufacturing processes that are widely used in the industry. Both processes have their unique advantages and disadvantages, and the choice of the manufacturing process depends on the specific needs of the application.

When it comes to CNC machining, one of the biggest advantages is the ability to create highly complex parts with great accuracy. This is especially important in industries such as aerospace and medical devices, where precision is critical for the safety and functionality of the product. Additionally, CNC Machine Parts Manufacturer can be programmed to produce identical parts repeatedly, which is important for mass production.

On the other hand, sheet metal fabrication is known for its speed and cost-effectiveness, making it a popular choice for producing parts in high volumes. The use of automated machines such as laser cutters and press brakes ensures consistent quality and precision, while reducing the time and labor required for manual fabrication.

It’s worth noting that both CNC machining and sheet metal fabrication require skilled operators and programmers to ensure the quality and accuracy of the final product. Additionally, the choice of materials used for each process can also affect the outcome, with CNC machining being better suited for harder materials such as metals and plastics, while sheet metal fabrication is better suited for softer metals such as aluminum and copper.

In conclusion, CNC machining and sheet metal fabrication are two essential manufacturing processes that have revolutionized the industry. From producing complex aerospace parts to mass-producing simple metal enclosures, these processes have greatly improved the efficiency, precision, and quality of manufacturing.