CNC machining for automotive applications is a process which involves the use of computer numerical control (CNC) machines for the production of parts used in cars and other vehicles. CNC machining can be used to produce a variety of components such as wheels, engine parts, and body components. It is essential for the precision and accuracy of the parts that they are produced using the most advanced technology available.

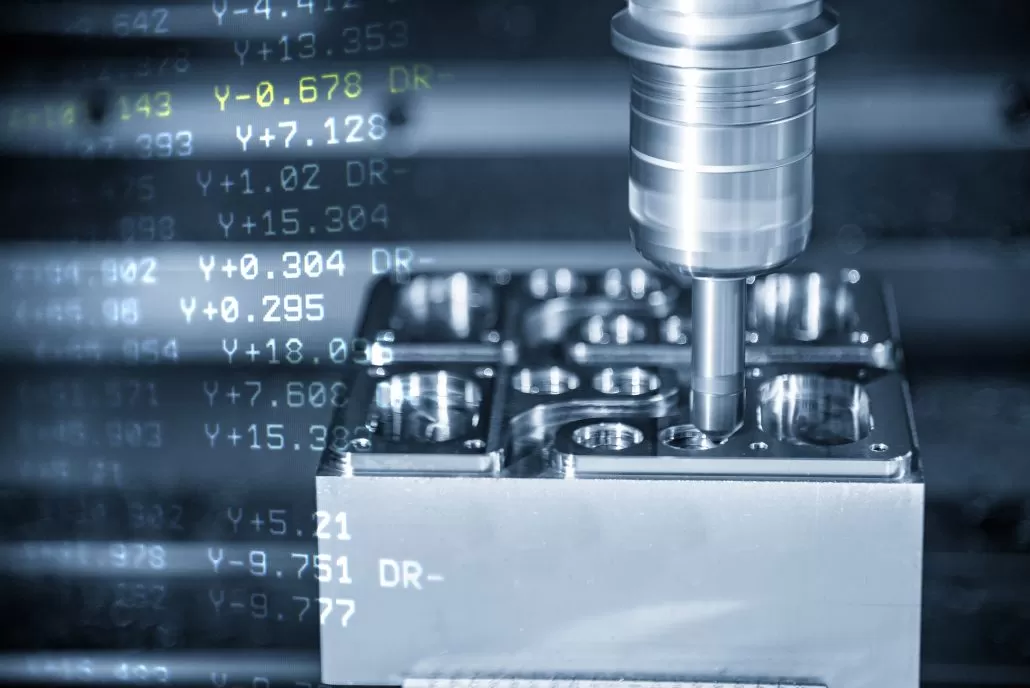

The CNC machining Service process begins with a part design created with the use of CAD software. This design is then converted into a program which is inputted into the CNC machine, giving it the commands necessary to produce the part. The raw material is then loaded into the machine and the part is cut by the cutting tools and shaped according to the part design. After the cutting is complete, the part is then finished and ready for assembly.

There are many advantages to having the parts produced with CNC machining. One of the biggest benefits is that the parts can be produced quickly and with high levels of precision. This allows for parts to be produced quickly enough to meet customer demands without sacrificing accuracy or quality. This also helps to reduce costs associated with production since the cost of materials and labor associated with manual manufacturing processes can be significantly reduced.

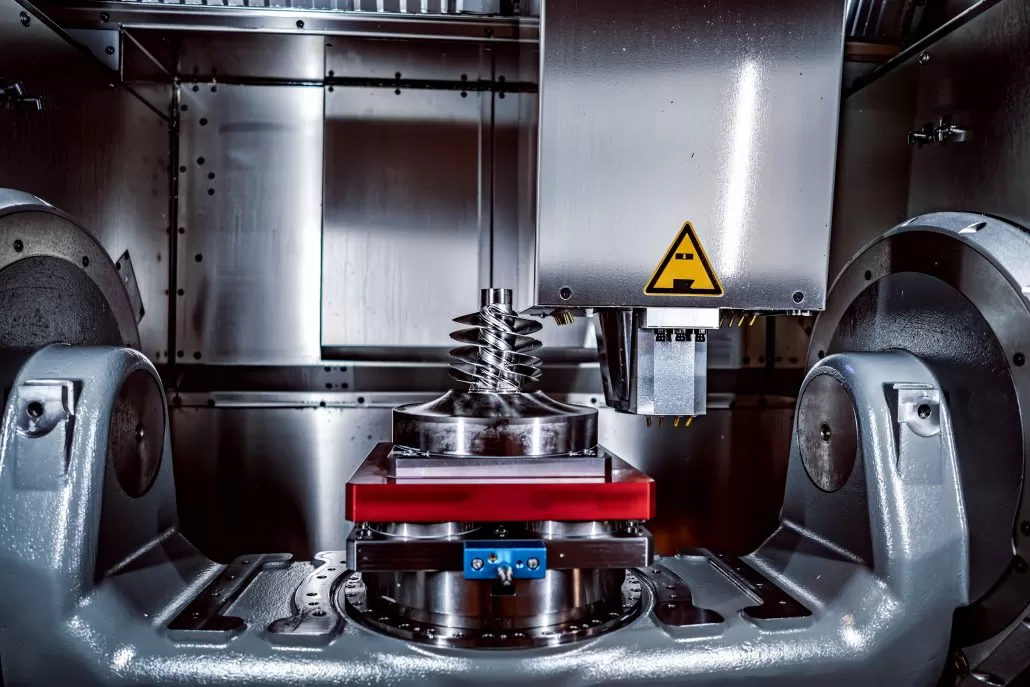

CNC machining can also be used to produce parts with complex designs. Parts such as engine blocks, wheels, and exhaust systems can be difficult and time consuming to produce using manual manufacturing processes, but they can be easily produced using CNC machining . Furthermore, the parts produced with CNC machines are often more durable than those produced manually, providing longer lasting parts with greater performance.

For automotive parts manufacturers, choosing a reliable CNC Machine Parts Manufacturer is essential. These manufacturers should provide quality products and services at competitive prices. Reliable manufacturers should have experience in the CNC machining field, allowing them to accurately produce parts with a wide range of complexity. Additionally, it is important to choose a manufacturer that is able to provide prompt delivery and excellent customer service.

Along with a trusted CNC Machine Parts Manufacturer, it is also important to choose a CNC Milling Parts Machining Service for automotive parts. This will ensure that all parts produced with CNC machining are accurate and have the right fit and finish. It also ensures that all parts meet the customer’s tight deadlines.

Finally, a Sheet Metal Machining Parts Center is another important service for automotive parts manufacturers. The center provides a wide range of services such as cutting, drilling, and grinding, ensuring that all parts fabricated with CNC machining have the highest quality finish possible. In addition, the center also offers the ability to customize parts according to customer specifications. This can include custom engraving and finishing, helping to create unique and unique parts for each customer’s needs.

Overall, CNC machining for automotive applications has become an essential part of the industry. With the help of a trusted CNC Machine Parts Manufacturer, CNC Milling Parts Machining Service, and Sheet Metal Machining Parts Center, parts can be quickly and accurately produced with precision and quality. This ensures that all parts produced meet the customer’s tight deadlines and expectations, providing them with high-performance parts that will last for years to come.