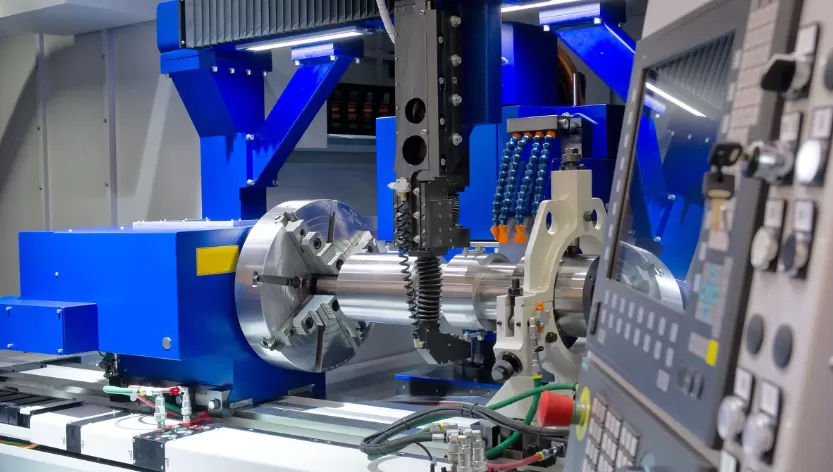

CNC machining has become an integral part of the medical device manufacturing process. The use of computer-controlled machines ensures precision and accuracy in the production of medical devices, which is critical in ensuring patient safety. In this article, we will discuss the benefits of using CNC machining for medical devices.

Precision and Accuracy

One of the primary benefits of using CNC machining for medical devices is precision and accuracy. Medical devices require high precision and accuracy to ensure they function as intended. CNC machines can produce intricate and complex designs with high precision, ensuring that the end product meets the required specifications.

Cost-Effective

CNC machining is a cost-effective manufacturing method for medical devices. The use of computer-controlled machines reduces the need for manual labor, which reduces the cost of production. Additionally, CNC machines can produce large quantities of medical devices quickly, reducing the cost per unit.

Versatility

CNC machines are versatile and can produce a wide range of medical devices. They can produce complex designs, such as surgical instruments, implants, and prosthetics, with ease. This versatility makes CNC machining a suitable manufacturing method for various medical devices.

Reduced Lead Time

The use of CNC machines in medical device manufacturing reduces lead time significantly. CNC machines can produce medical devices quickly and accurately, reducing the time it takes to get the product to market. This reduced lead time is critical in the medical device industry, where time is of the essence.

Conclusion

In conclusion, CNC machining is an essential manufacturing method for medical devices. Its precision, cost-effectiveness, versatility, and reduced lead time make it a suitable method for various medical devices. Businesses in the medical device manufacturing industry should consider CNC machining when seeking a manufacturing method that meets their needs.

Choosing the Right CNC Machining Service Provider

When looking for a CNC machining service provider for medical devices, businesses should consider several factors. The first is the service provider’s experience and expertise in the industry. A service provider with several years of experience in manufacturing medical devices is likely to provide high-quality services compared to one who is just starting.

Secondly, businesses should consider the service provider’s equipment and technology. A service provider with modern machines and tools is likely to produce better quality medical devices than one with outdated equipment.

Another factor to consider is the service provider’s reputation. Businesses should look for service providers with positive reviews from previous clients. This is an indication that the service provider provides high-quality services.

Finally, businesses should consider the cost of services. While it is essential to choose a service provider with affordable services, businesses should not compromise on quality. It is better to pay more for high-quality services than to pay less for substandard services.

Conclusion

CNC machining is crucial in the medical device manufacturing process. Its precision, cost-effectiveness, versatility, and reduced lead time make it a suitable method for various medical devices. When choosing a service provider, businesses should consider their experience, equipment, reputation, and cost of services to ensure they get high-quality services that meet their needs.

CNC Machining and Medical Device Innovation

CNC machining has also contributed to the innovation of medical devices. With the help of computer-aided design (CAD) software, medical device manufacturers can create intricate and complex designs that were previously impossible to produce. CNC machines can then produce these designs with accuracy and precision, giving rise to new medical devices that were once unthinkable.

The use of CNC machining has also made it possible to produce medical devices with improved functionality and patient outcomes. For instance, CNC machines can produce implants with porous structures that encourage bone ingrowth, leading to better fixation and reduced implant failure rates.

CNC Machining and Patient Safety

Patient safety is of utmost importance in the medical device industry. CNC machining has played a significant role in ensuring patient safety in medical device manufacturing. CNC machines can produce medical devices with high precision and accuracy, ensuring that they meet the required specifications. This precision and accuracy reduce the risk of medical device failure, which can cause harm to patients.

Additionally, CNC machines can produce medical devices with consistent quality, reducing the risk of defects and inconsistencies that can compromise patient safety.

Conclusion

CNC machining is a critical manufacturing method for medical devices. Its precision, cost-effectiveness, versatility, and reduced lead time make it a suitable method for various medical devices. Additionally, CNC machining has contributed to the innovation of medical devices and has played a significant role in ensuring patient safety. Businesses in the medical device manufacturing industry should consider CNC machining when seeking a manufacturing method that meets their needs.

Future of CNC Machining in Medical Device Manufacturing

The future of CNC machining in medical device manufacturing looks promising. As technology advances, CNC machines are becoming more sophisticated, allowing for the production of even more intricate and complex designs. Additionally, CNC machines are becoming more affordable, making them accessible to more medical device manufacturers.

Furthermore, the use of CNC machining in conjunction with other technologies such as 3D printing and robotics is likely to revolutionize medical device manufacturing. For instance, the combination of CNC machining and 3D printing can produce medical devices with complex geometries and internal structures that were previously impossible to produce.

In conclusion, CNC machining is set to play a significant role in the future of medical device manufacturing. Its precision, cost-effectiveness, versatility, and reduced lead time make it an attractive manufacturing method for medical devices. Additionally, the continued advancement of CNC machining technology is likely to lead to even more innovation and improvement in medical device manufacturing.

Pingback: CNC Prototyping Services Online | Custom Aluminum CNC Parts

Hi my loved one! I wish to say that this post is amazing, great written and include approximately all significant infos. I¦d like to look extra posts like this .

Usually I don’t read post on blogs, but I would like to say that this write-up very forced me to try and do so! Your writing style has been amazed me. Thanks, quite nice article.

Dead written subject matter, Really enjoyed reading.

Whats up very cool site!! Man .. Excellent .. Wonderful .. I’ll bookmark your blog and take the feeds also…I am glad to search out numerous helpful info right here in the post, we’d like develop more techniques in this regard, thanks for sharing.