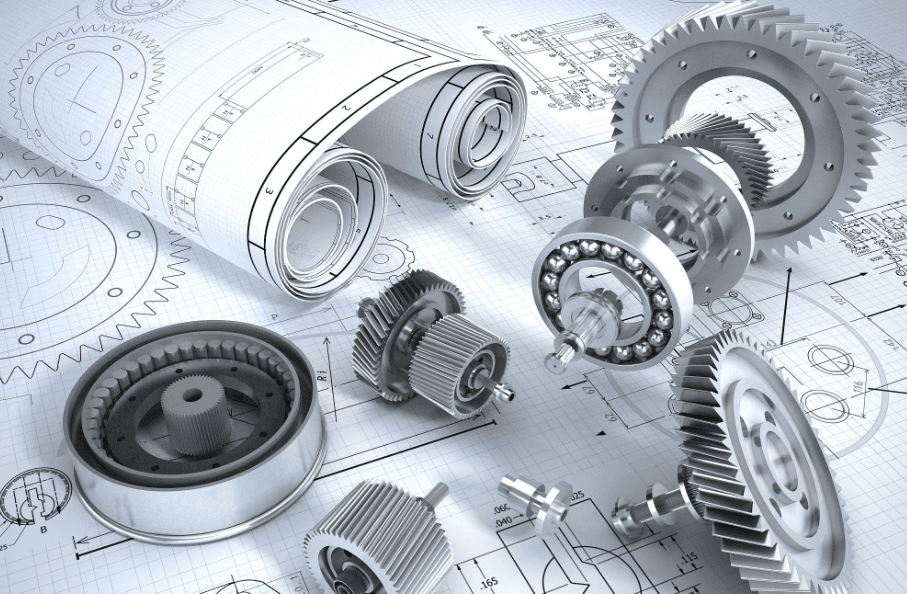

CNC Machining for the Defense Industry: Ensuring Quality and Precision

CNC machining plays a critical role in the defense industry, where precision and quality are paramount. From aerospace components to military equipment, CNC machining parts are used in a variety of applications.

When it comes to defense, there is no room for error. That’s why it’s crucial to choose the right CNC machining parts for your specific needs. Here are some tips to ensure that you get the best quality and precision for your defense applications.

Identify Your Requirements

The first step in choosing the right CNC machining parts is to identify your requirements. You need to determine what kind of parts you need, the materials they should be made of, and the expected volume of production. Knowing these details will help you narrow down your options and choose the parts that will best suit your needs.

Consider the Quality of the Parts

Quality is paramount in the defense industry. You need to make sure that the parts you choose can withstand the rigors of your application and meet the quality standards of the industry. Look for suppliers with a good reputation for providing high-quality parts to ensure that you get the best value for your money.

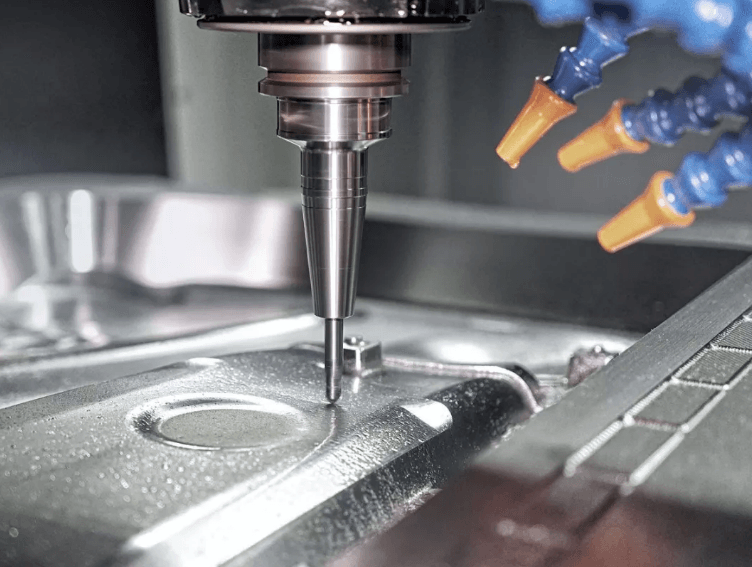

Evaluate the Supplier’s Capabilities

When choosing CNC machining parts for the defense industry, it’s important to evaluate the supplier’s capabilities. Look for suppliers with the necessary equipment, experience, and expertise to handle your specific requirements. You should also consider the supplier’s lead times, delivery times, and customer service to ensure that they can meet your production needs.

Choose a Supplier with Experience in the Defense Industry

When it comes to defense applications, it’s important to choose a supplier with experience in the industry. Look for suppliers that have worked with defense contractors and have a thorough understanding of the industry’s requirements and regulations.

Check for Certifications

Certifications such as ISO 9001 and AS9100 are essential in the defense industry. These certifications indicate that the supplier has met certain quality standards and has the necessary processes in place to ensure consistent quality. Checking for certifications can give you peace of mind that you’re working with a reputable supplier.

Consider Customization Options

Depending on your defense application, you may require customized CNC machining parts services. If this is the case, you should look for suppliers that offer customization options. This will allow you to create parts that are tailored to your specific requirements. It’s important to note that customization may come at an additional cost, so make sure to consider this in your budget.

Don’t Compromise on Quality

When it comes to defense applications, quality cannot be compromised. Choosing low-quality parts can result in critical failures that could have serious consequences. It’s important to prioritize quality when choosing CNC machining parts for the defense industry.

In conclusion, choosing the right CNC machining parts for the defense industry requires careful consideration of several factors such as your requirements, the quality of the parts, the supplier’s capabilities, experience in the industry, certifications, customization options, and quality. By taking the time to evaluate these factors, you can ensure that you’re making an informed decision that will benefit your defense applications in the long run.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items