CNC machining is a crucial process for many industries, producing high-precision parts with accuracy and efficiency. However, not all CNC machining parts services are created equal. To ensure that your parts are produced to the highest standard, it is important to choose a reliable and high-quality service provider.

The Importance of Quality CNC Machining Services

High-quality CNC machining services can provide numerous benefits for your business. With precision parts, you can improve the quality of your products, reduce waste, and increase efficiency. Additionally, high-quality parts can improve the overall safety and reliability of your products, reducing the risk of failures or accidents.

Tips for Choosing a Quality CNC Machining Service

When choosing a CNC machining service provider, there are several factors to consider. Look for a company with a proven track record of producing high-quality parts, certifications from recognized organizations, modern and high-quality equipment, and excellent customer service. By choosing a reputable provider, you can be confident that your parts will be produced to the highest standard.

Reducing Costs through CNC Machining Services

While CNC machining can be costly, there are ways to reduce costs without sacrificing quality. By optimizing your design for manufacturing, choosing the right material, using standard parts, and optimizing batch size, you can reduce the overall cost of your project. Additionally, by choosing a reputable CNC machining service provider, you can benefit from their expertise in cost reduction strategies.

Conclusion

CNC machining services can provide numerous benefits for your business, from improved product quality to increased efficiency. By choosing a high-quality service provider and implementing cost reduction strategies, you can meet your precision parts needs while minimizing costs. Choose a reliable CNC machining service provider today and experience the benefits of precision parts.

The Benefits of CNC Machining Services

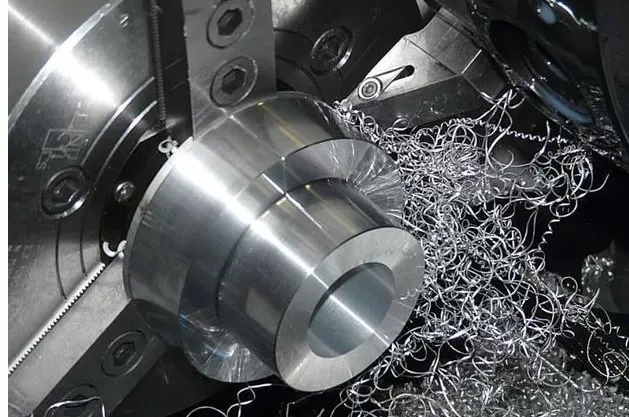

CNC machining services offer several benefits that traditional machining methods cannot. With computer-controlled machines, CNC machining provides unparalleled precision and accuracy, resulting in high-quality parts that meet your exact specifications. Additionally, CNC machining can produce complex geometries and shapes that would be difficult or impossible to produce with traditional machining methods.

CNC machining services are also highly efficient, with the ability to produce parts quickly and with consistent quality. This efficiency translates to cost savings, as you can produce more parts in less time, reducing overall production costs.

Applications of CNC Machining Services

CNC machining services are used in a wide range of industries, from aerospace and automotive to medical and electronics. CNC machining is particularly useful for producing parts with complex geometries or tight tolerances, such as engine components, medical implants, and electronic housing.

Choosing the Right CNC Machining Service Provider

Choosing the right CNC machining service provider is crucial to ensuring that your precision parts needs are met. Look for a company with experience in your industry, certifications from recognized organizations, and modern equipment. Additionally, a company with a strong reputation for customer service can ensure clear communication throughout the production process and provide support if any issues arise.

Conclusion

CNC machining services provide several benefits for businesses that require precision parts. By choosing a high-quality service provider and implementing cost reduction strategies, you can meet your precision parts needs while minimizing costs. Consider partnering with a reputable CNC machining service provider today and experience the benefits of precision parts in your products.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key itemsPost navigation