As a business owner or engineer, you know how important it is to understand the internal working principles of CNC machining. One of the most common questions is “How long does CNC machining take?” In this article, we will delve into all the information you need to know about CNC machining, including how long the process takes and the factors that may affect the time frame.

Understanding the CNC Machining Process

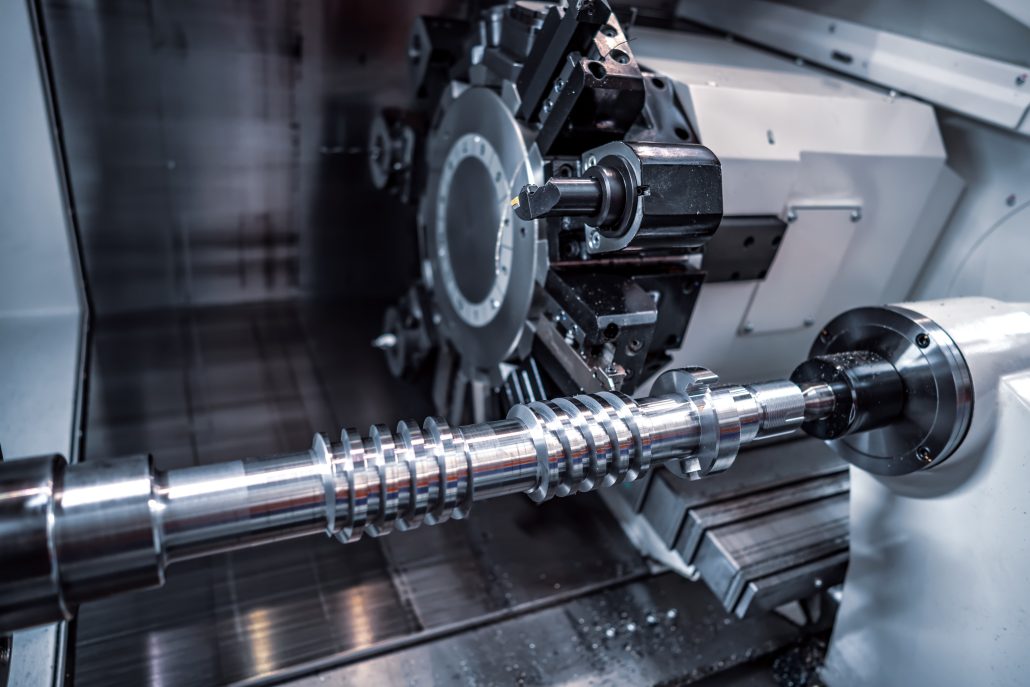

Before we dive into the time aspect, it’s essential to understand the CNC machining process. CNC stands for Computer Numerical Control, a technology that uses computer programs and coded instructions to control the movement of machines. Essentially, CNC machining involves feeding a design into a computer, which translates the instructions into machine code. This code is then used to direct a CNC machine to cut, drill, mill, or shape a piece of material (metal, plastic, wood, etc.) into a finished product.

There are several steps involved in this process, including:

Design: To create a CNC program, you first need a design. This can be done using CAD software or by scanning an existing object.

Program: Once you have the design, you’ll need to program it into the CNC machine. This involves writing code to control the machine’s movements based on the design specifications.

Setup: After the program is loaded, you’ll need to set up the machine. This includes installing tools, clamping the workpiece, and aligning the machine with the material.

Machining: Once everything is set up, the machine will start cutting, drilling, or milling the material according to the program.

Finishing: Finally, the finished product will need to be cleaned, deburred, and polished to ensure it meets the required specifications.

So, with all these steps involved, how long does CNC machining take?

How Long Does CNC Machining Take?

The length of time it takes for CNC machining depends on various factors. Primarily, it is influenced by the complexity of the design and the type of material to be machined. For instance, a simple design takes less time to process than a complex one. Similarly, a harder material will take more time to machine than a softer one.

CNC machining work at a set speed, which is determined by the type of tool being used and the material being machined. The average speed of a CNC machine is around 1 foot per minute (12 inches/min). Thus, the length of time it takes for a machine to complete a job is determined by the length of the material that needs to be machined, as well as the depth needed to remove the material.

| CNC Machining Task | Estimated Processing Time |

|---|---|

| Part Cutting | 30 minutes – 2 hours |

| Part Milling | 1 hour – 4 hours |

| Hole Machining | 30 minutes – 2 hours |

| Thread Machining | 30 minutes – 2 hours |

| Surface Grinding | 1 hour – 3 hours |

| Part Polishing | 1 hour – 3 hours |

| Part Deburring | 1 hour – 4 hours |

| Part Assembly | 30 minutes – 2 hours |

Factors Affecting CNC Machining Lead Time

Several variables can affect the lead time for CNC machining parts. Here are the most critical factors:

1.Part Complexity

The complexity of the part being produced is one of the primary factors that determine how long CNC machining takes. Simple parts with basic geometries take less time to produce than complex parts with intricate designs.

For example, a simple block may take only a few minutes to produce, while a complex part with intricate details may take several hours or even days to complete.

2.The Material

The material used for the part also plays a significant role in determining the machining time. Plastic parts typically take less time than metal parts. Soft metals like aluminum and brass are easier to machine than harder metals like stainless steel, which take more time.

3.Machining Process

Different machining processes, such as milling, turning, and drilling, have varying lead times. Turning, for example, is generally faster and more cost-effective than milling for producing cylindrical shapes.

4.Equipment Capacity and Availability

The size and capacity of the machine used also affects the machining time. Larger machines are capable of producing bigger parts and can work on multiple parts simultaneously, reducing the time needed. Additionally, the availability of equipment can impact lead time, as some manufacturers may have a backlog of orders.

5.CNC Machine Type

The type of CNC machine used also plays a significant role in determining how long CNC machining takes. High-speed machines with advanced cutting capabilities can produce parts faster than older or less advanced machines.

Modern CNC machines are equipped with sophisticated software and hardware that can work on several processes simultaneously, which speeds up machining time.

6.Order Quantity

The number of parts you want to produce also determines the machining time. Larger orders will take more time than smaller ones, as multiple parts will need to be machined.

What’s the Typical Lead Time for CNC Machining?

The lead time for CNC machining can vary widely depending on the factors listed above. However, in general, most orders take anywhere from a few days to a few weeks. The complexity and material of the part typically play the most significant role in determining lead time. Most machining shops provide a quote before beginning work, where they estimate the time it takes to complete the order based on the specifications.

How to Optimize CNC Machining Time

1.Simplify Part Design

One way to reduce CNC machining time is by simplifying part design. Reducing the complexity of the part design can significantly reduce machining time, which can translate to lower production costs.

2.Use High-Speed Machines

Using high-speed CNC machines can help to optimize production time. High-speed machines have faster spindle speeds, which allows for faster cutting and better surface finishes.

3.Use Appropriate Material

Using appropriate materials can help to reduce CNC machining time. Using materials that are easier to machine, like aluminum or plastic, can reduce machining time significantly.

In conclusion, how long CNC machining takes depends on several factors, including part complexity, material type, and CNC machine type. By simplifying part design, using high-speed machines, and appropriate materials, you can optimize production time and reduce costs.

At CNC Parts Online, we offer a wide range of CNC and turning parts online, and we are committed to delivering top-quality parts at competitive prices. Contact us today to learn more about our products and services.

Tips for Faster CNC Machining

While there’s no way to eliminate the necessary steps involved in CNC machining, there are several things you can do to speed up the process:

Simplify designs: If possible, simplify your designs to reduce programming and machining time.

Use efficient tool paths: Optimizing tool paths can significantly reduce machining time.

Utilize high-speed machining: High-speed machining can increase production rates without sacrificing accuracy.

Invest in quality tooling: High-quality tools will last longer and cut faster, reducing machining time.

Reduce setup time: Streamline your setup process to minimize downtime.

In summary, the time required for CNC machining may vary due to various factors. However, by understanding the process and adopting some optimization strategies, you can significantly shorten production time while maintaining high-quality parts. If you are looking for CNC parts online, you can consider collaborating with a reputable supplier