Do you want clarification about CNC machining vs. injection molding? Which technique can precisely meet your necessities and undertaking specs depends on your design. Nevertheless, the distinct manufacturing effectiveness, accuracy, lead time, and price implications of those two methods make it challenging to decide on the correct one. Furthermore, they work on essentially different rules.

CNC machining creates the specified half by eradicating the fabric with slicing instruments. In distinction, the injection molding technique includes injecting the molten materials into a mildew that comprises the detrimental geometry of the specified form.

Moreover, we will cover different facets of Injection molding and CNC manufacturing to differentiate between these processes analytically.

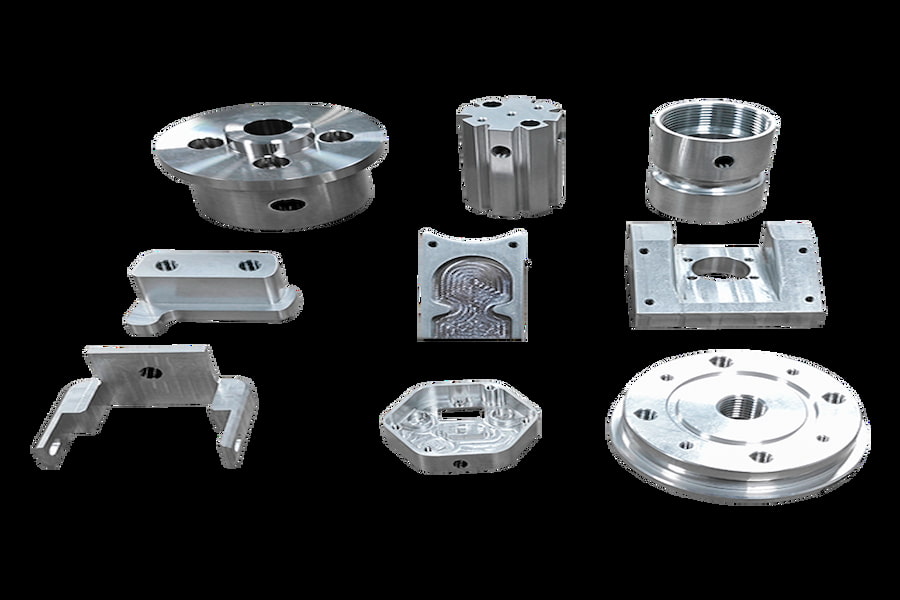

What’s CNC Machining?

It’s a subtractive manufacturing technique that stands for computer numerical management. The CNC machining process creates the designed form by eradicating the fabric from the workpiece with appropriate slicing instruments. In this course, pre-programmed computer software dictates the motion of instruments and equipment. As a consequence, it permits the exact management of advanced equipment.

The method begins with making a digital 2D and 3D design. This design acts as a blueprint for the CNC machine. In the meantime, the CNC system interprets the design, transitioning from design to manufacturing. It converts it into numbers and coordinates, and parameters like slicing charge, depth, and others must be entered. Then, these coordinates inform the machine’s actions to control the workpiece form.

Thus, it’s essential in industries requiring excessive accuracy ranges, similar to aerospace, automotive, and medical.

Execs of CNC Machining

- The precision of CNC machining is outstanding. It could provide tolerances as little as 0.0001 inches.

- CNC machining is flexible. It works with numerous supplies, such as Metals, plastics, and composites. Additionally, CNC machines can rapidly adjust partial designs.

- In CNC machining, there is no vital time and funding for tooling and molding. So, it gives a fast turnaround for prototyping and small batches.

Cons of CNC Machining

- Plastic CNC machining doesn’t need ordinary mildew for mass manufacturing. So, it repeats the identical steps for every cycle, making it costlier in large manufacturing.

- The subtractive nature of CNC machining restricts its means to realize the identical stage of form complexity and high-quality detailing as injection molding.

What’s Injection Molding?

The injection molding course makes the specified parts or merchandise by injecting the molten materials into an injection mold below stress. The molds comprise cavities based on the geometry of the intended form. Upon cooling, the fabric solidifies into the specified form. Lastly, opening the mold and injecting the solidified parts completes the method. Nevertheless, generally, molded parts require post-machining or floor-ending remedies to satisfy the required specs.

The plastic molding course’s setup includes three models: mold, Injection, and Clamping unit.

Firstly, Injection Mould consists of two halves that come collectively to type the cavity into which the molten materials are injected. Secondly, the injection unit heats and injects the fabric into the mildew. It melts the plastic pellets and forces the liquid into the mildew cavity via stress. Thirdly, the clamping unit holds the mildew halves tightly collectively through the injection and cooling. As soon as the fabric solidifies, the clamping unit opens the mildew to eject the half.

Execs of Injection Molding

- This method is economical for large-scale manufacturing runs, as mildew is usable for several thousands to tens of millions of manufacturing cycles under correct upkeep.

- It molds supplies into advanced shapes with precision. It is dependent upon the cavity intricacies.

- A single mildew is relevant for several molding cycles. So, it produces parts with uniform precision and high quality, guaranteeing excessive effectivity and repeatability.

Cons of Injection Molding

- In contrast to CNC machining, it includes making a mildew first earlier than precise manufacturing. It makes injection molding costlier in CNC machining vs injection molding comparability.

- Not all supplies are appropriate for injection molding. It’s generally splendid for thermoplastic parts. Subsequently, the mildew design should accommodate the capabilities of molding machines, limiting inventive flexibility.

- Growing and producing molds takes time. It could lengthen the general timeline from idea to manufacturing, affecting undertaking schedules.

CNC Machining vs Injection Molding: Key Variations

| Standards | CNC Machining | Injection Molding |

| Materials Variety and Choice | It’s suitable for numerous extra supplies, metals, plastics, and composites. | They are predominantly used for plastic supplies. |

| Tolerances | As little as ±0.001″. | Sometimes ±0.003″. |

| Design Flexibility and Limitations | Able to create extra intricate inner options like undercuts. | It is much less versatile for inner geometries |

| Time Effectivity From Prototype to Manufacturing | Fast, usually a couple of hours per week or month. | Time-consuming as a consequence of CNC mildew-making |

| Manufacturing Quantity | Most well-liked for prototyping or small volumes. | Medium to giant volumes |

| Closing Product High Quality and Precision | Extra exact and wonderful as-machined floor finishes(Ra 0.8-3.2 µm) | Would possibly require post-machining or processing |

| Tooling Longevity and Upkeep Necessities | Frequent instrument alternative | A mildew is relevant for quite a few cycles |

| Price-effectiveness for Totally different Manufacturing Volumes | Fast prototyping to shot-run manufacturing | Identical parts in giant numbers |

Deciding on injection molding vs CNC machining requires an in-depth evaluation of various technical capabilities and price implications. In the meantime, typical comparability standards are materials choices, precision, high quality, design flexibility, and cost-effectiveness. So, let’s examine these two manufacturing processes to determine the significant variations.

Materials Variety and Choice

CNC machining suits numerous supplies, including metals, plastics, ceramics, and composites. This range permits intensive material choice primarily based on the precise needs of the meant software, such as power, weight, or thermal properties. Conversely, injection molding is appropriate for plastics and a few metals. Nevertheless, it gives a broad choice inside these classes.

Tolerances

CNC machining is famed for its functionality in realizing tight tolerances. The CNC precision machining processes can obtain tolerances of ±0.001. This precision is crucial for industries where minute discrepancies can influence performance.

Alternatively, injection molding gives slightly less tight tolerances (±0.003 mm) but is nonetheless exact. Subsequently, the character of the molding process and material habits throughout cooling can introduce variability.

Design Flexibility and Limitations

Injection molding can produce parts with advanced geometries and complicated particulars, particularly for parts that can be difficult to machine. Nevertheless, it requires moldable designs, contemplating elements like draft angles and undercuts.

Alternatively, CNC machining struggles with very advanced inner geometries. Nevertheless, it gives greater flexibility in design modifications because you can make changes by altering this system code.

Time Effectivity from Prototype to Manufacturing

If we analyze CNC machining vs plastic injection molding, which technique is environment-friendly for prototyping? The reply is CNC machining. Once more, the reason is the extra mold-making course for injection molding prototyping. In the meantime, CNC doesn’t require the creation of mildew.

Consequently, transitioning from a CNC prototype to manufacturing is seamless, with changes made via programming. Nevertheless, subsequent manufacturing cycles are fast and correct in injection molding when you create mildew.

Manufacturing Quantity

After the preliminary funding for injection mildew, the price of every subsequent cycle decreases as the identical mildew can repeat quite a few cycles. Alternatively, CNC machining is cost-effective for low to medium volumes, so the excessive injection mildew price shouldn’t be possible.

Closing Product High Quality and Precision

Though each process ships high-quality parts, CNC machining immediately gives superior precision and floor end off the machine. Injection molded parts would possibly require extra ending processes to realize the specified floor’s high quality. This post-processing is very obligatory for plastic injection molded parts with advanced geometries or the place the mildew has begun to put on.

Tooling Longevity and Upkeep Necessities

Injection molds are more complex to install than CNC tooling, so switching or restoring in high-volume manufacturing runs may be more costly. Nevertheless, inspection and standard upkeep contribute to constant quality and longer life.

- Injection Mould: Excessive price and extra longevity(from hundreds to tens of millions of cycles, depending on the type of injection mold)

- CNC tooling: Much less longevity, however economical for changing.

Alternatively, CNC tooling (such as slicing instruments, jigs, and fixtures) also requires upkeep over time. Nevertheless, the cost of changing these tooling is more economical than molding.

Price-effectiveness for Totally different Manufacturing Volumes

The excessive upfront mildew price in injection molding can solely justify the worth of manufacturing in giant volumes, except the designed half is barely suitable for molding. The following checklist demonstrates the associated fee compatibility of injection molding vs. CNC machining below different manufacturing quantity eventualities.

- Prototyping: CNC machining is highly economical

- Small Batches: CNC machining

- Medium Volumes: CNC machining/ Injection molding primarily based on particular eventualities

- Mass-production: Injection molding

Alternatively, CNC doesn’t match the associated fee of low-cost injection molding in large volumes. According to CNC machining cost calculation, the per-unit price decreases in much less quantity as the quantity increases.

What are the similarities between CNC machining and injection molding?

We’ve mentioned the essential variations between CNC machining and Injection molding. Nevertheless, there are additionally a couple of similarities between these methods. They are often similar to plastic molded parts and machined plastic parts.

Precision and Accuracy

Computer numerical management makes CNC machining an exact technique. Similarly, correct mold and computer-controlled injection molding mechanisms can mold high-performance plastics with tight tolerances. So, both strategies ensure merchandise meets strict specs.

Advanced Geometries

Another similarity is intricate geometry capabilities. The proper tooling and machining parameters could create advanced geometry and options. Likewise, injection molding captures each design element inside its mildew design concerns. In the meantime, molding is superior for intricate patterns on skinny plastic elements.

Materials Selection

Materials versatility is another frequent floor. CNC machining processes a broad spectrum of supplies, from metals and composites to plastics. This flexibility helps numerous manufacturing needs. Injection molding parallels this with its capability to mold innumerable plastics. Every plastic sort brings distinctive properties, from warmth resistance to UV resistance. Thus, each applied science adapts to different material necessities.

Design Modification

Design adjustments are seamless in CNC machining because they depend on updating CAD information. For injection molding, mildew modifications are doable before mass manufacturing. This adaptability facilitates fast prototyping and iteration. It permits designers to refine the CNC machined merchandise without vital cost or time investment. Because of this, each process accommodates design modification.

Significance in Product Improvement

These strategies speed up the process from idea to market and guarantee prototypes match remaining product requirements. It would be best to use small injection molding machines to provide prototypes earlier than full-scale runs. Furthermore, each strategy supports swift manufacturing scaling. This significance is crucial in aggressive markets where pace and high quality are significant. Thus, CNC machining and injection molding are essential in bringing improvements to life.

Making Your Resolution: Select LongSheng for CNC Machining and Injection Molding Companies

From the above dialogue, you can get a concept for selecting between CNC machining and plastic injection molding. It depends upon various factors: Materials sort, manufacturing quantity, design complexity, and meant tolerances. Nevertheless, it’s wise to seek the advice of trade consultants like LongSheng earlier than your remaining resolution. LongSheng is the number one CNC machining service provider. The superior multi-axis CNC methods on the LongSheng manufacturing unit can convert your design to the specified specs. Our engineers intently work with purchasers to perceive the necessities first. So, we will customize the merchandise primarily based on the meant use.

Moreover, our injection molding services are tailor-made to provide high-quality injection molding plastic elements with excellent floor ends. We additionally offer design modification and seamless scalability for top manufacturing runs. In the meantime, you don’t have to think about mildew-making. Our devoted staff handles your superior mildew design and plastic mildew manufacturing.

Add your design and leverage the distinctive, high-quality management and materials choices for your CNC-machined and injection-molded parts at LongSheng!

Different Comparisons for CNC Machining or Injection Molding

CNC Machining vs 3D Printing

3D Printing is an additive manufacturing technique. It builds the design by including the layers one after the other. In distinction, the subtractive method of CNC machining removes materials to realize the ultimate half.

| Standards | CNC Machining | 3D Printing |

| Strengths | Presents precision and power | Excels in complexity and customization |

| Materials Compatibility | Works with metals, composites, ceramics, plastics, and different supplies. | It is restricted to polymers. However, it can cause some metals and composites. |

| Effectivity for Excessive-Quantity | The extra environment friendly, however, comes with increased setup prices | Not appropriate for large-volume manufacturing. |

| Price-Effectiveness for Small Batches | Decrease price | Price-effective and permits fast prototyping with minimal setup |

CNC Machining vs Standard Machining

Firstly, standard machining is the muse for our machining innovation. It depends on the guide operation. Expert machinists inform the instruments, providing flexibility and craftsmanship. Thus, standard strategies provide hands-on adaptability. In distinction, the computer automation of CNC makes it exact, environment-friendly, and quick.

Though standard machining is slower, it may compete with CNC in customized tasks with medium tolerance. Right here, the machinist’s experience can navigate distinctive challenges. Nevertheless, automated methods may not accommodate these challenges.

Subsequently, materials wastage and price implications further distinguish these two processes. CNC machining minimizes materials waste and results in price financial savings in large-scale operations. Alternatively, standard machines would possibly produce extra scrap. However, it requires a decrease in preliminary funding.

Injection Molding vs Die Casting

One common feature of these two strategies is that they use mildew to form the intended half. Nevertheless, injection molding primarily uses thermoplastic and thermosetting polymers, whereas die casting is principally for non-ferrous metals like aluminum, zinc, and magnesium. This fundamental distinction in materials compatibility dictates their use in numerous industries.

- Injection Molding: Plastics dominate industries like client items and electronics

- Die Casting: Automotive and industrial elements result from its steel processing functionality.

Moreover, low-pressure plastic injection molding allows exact and advanced shapes. Conversely, die casting can produce high-strength parts with thinner partitions and nearer dimensional tolerances, so it’s splendid for steel and alloy parts. Subsequently, injection molding is faster and more appropriate for mass manufacturing.

Injection Molding vs Extrusion

Extrusion pushes materials via a die, creating steady shapes by die design. It’s splendid for producing profiles like pipes and sheets. Thus, extrusion is about size and uniformity. Alternatively, injection molding focuses on elements and complexity.

| Side | Injection Molding | Extrusion |

| Course of | Injects molten materials right into a mildew | Pushes materials via a die |

| Materials | Primarily thermoplastics and thermosets | Plastics and metals like aluminum |

| Measurement | Suited to small to medium-sized parts | Finest for lengthy and steady profiles |

| Velocity | Quick cycle instances for high-volume manufacturing | Additionally Quick |

| Precision | Excessive precision with tight tolerance management | Constant cross-sectional profiles, however, are much less exact than molding |

Subsequently, precision in injection molding is increased, providing tight tolerance management. Extrusion gives constant cross-sectional profiles but less dimensional accuracy than molding.

Compression Molding vs Injection Molding

Compression molding doesn’t inject the fabric right into a mildew-like injection strategy. The required materials are first weighed and stored in compression mildew as a substitute. In the meantime, the mildew cavities are sometimes heated to enhance the circulation contained in the mildew throughout compression. This technique is well-suited for giant, simple-shaped, and sturdy parts in small to medium volumes.

Alternatively, thermoplastic is the frequent injection molding material. It’s incredibly environment-friendly for large-scale manufacturing of small to medium-sized parts with quick cycle instances. Nevertheless, compression molding gives price advantages for some tasks by lowering waste and utilizing less complicated equipment.

Blow Molding vs Injection Molding

The blow molding process focuses on molding hole objects similar to bottles and containers. This course begins with melting the plastic and forming it into a preform or parison. In contrast to injection molding, it’s then inflated inside mildew to realize the specified form.

It predominantly uses thermoplastic and fits for giant volumes with uniform wall thickness. Injection molding, conversely, is adept at producing stable, intricate parts by injecting molten plastic right into mildew at excessive stress.

Conclusion

Lastly, each manufacturing process is advantageous when you select the correct one based on your undertaking specs. The everyday concerns for CNC machining vs. Injection molding are materials, form complexity, manufacturing quantity, wall thickness, and required tolerances.

Moreover, alternative options exist if plastic molding and CNC machining do not suit your design. You can select from 3D Printing, die casting, compression molding, and blow molding.

Awesome write ups, Regards!