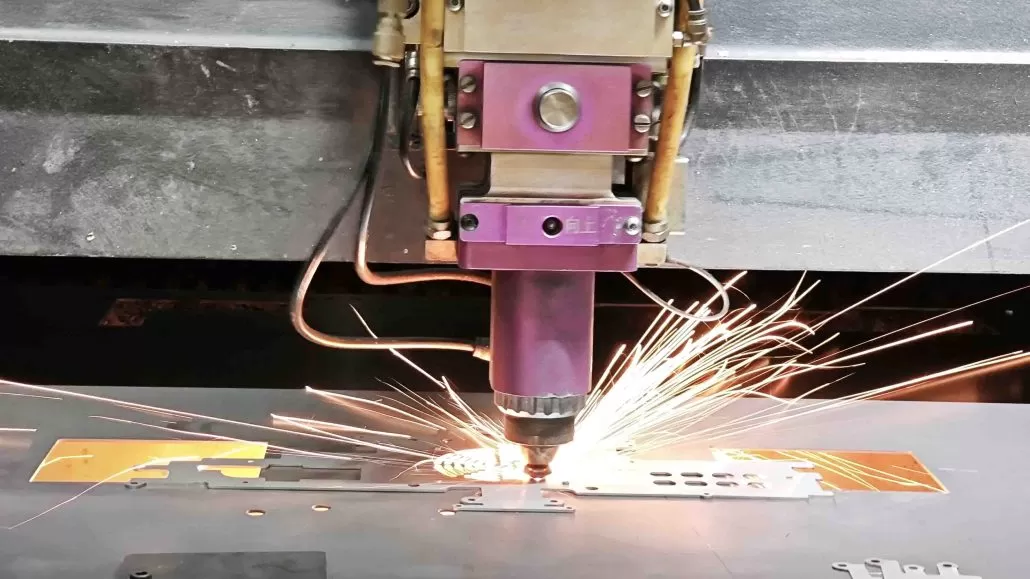

CNC metal cutting is a highly advanced and precise manufacturing process that involves the use of computer software to control the movement of cutting machines. This technology has completely revolutionized the way metal is cut, making the process faster, more accurate, and less labor-intensive.

The use of CNC metal cutting has become increasingly popular in the manufacturing industry due to its many advantages over traditional metal cutting methods. With this technology, manufacturers can achieve greater precision and accuracy, reduce lead times, and produce complex designs that would be difficult or impossible to create using other methods.In this article, we will take a closer look at CNC metal cutting, including its process, advantages, and various applications.

CNC Metal Cutting and its Process

CNC metal cutting is a manufacturing process that involves the use of computer software to control the movement of cutting machines. This technology has revolutionized the way metal is cut, making the process faster, more accurate, and less labor-intensive.

The process of CNC metal cutting involves the following steps:

- Designing the part: The first step in CNC metal cutting is to create a digital design of the part to be cut using computer-aided design (CAD) software.

- Converting the design: The CAD file is then converted into a format that the CNC machine can understand, such as G-code.

- Setting up the machine: The CNC machine is then set up with the appropriate cutting tool, and the material to be cut is secured in place.

- Running the program: The G-code program is loaded into the CNC machine, and the cutting process begins. The machine follows the instructions in the program to move the cutting tool along the material, cutting away excess material until the part is formed.

CNC metal cutting has many advantages over traditional metal cutting methods. It is faster, more accurate, and can be used to create complex shapes and designs. Additionally, it requires less human labor, as the CNC machine does most of the work.

In conclusion, CNC metal cutting is a highly efficient and precise manufacturing process that has revolutionized the metalworking industry. By using computer software to control cutting machines, it has made the process faster, more accurate, and less labor-intensive.

Advantages of CNC Metal Cutting

CNC metal cutting has many advantages over traditional metal cutting methods. One of the most significant advantages is its accuracy. With tolerances as small as 0.001 inches possible, CNC metal cutting can achieve levels of precision that are difficult or impossible to achieve with other methods.

Another advantage of CNC metal cutting is its speed. Because the computer software controls the cutting process more precisely and quickly than a human operator, CNC metal cutting is generally faster than traditional metal cutting methods.

CNC metal cutting is also highly versatile. It can be used to cut a wide range of materials, including steel, aluminum, copper, brass, and titanium. Additionally, it can be used to create complex shapes and designs that would be difficult or impossible to achieve with other methods.

Applications of CNC Metal Cutting

CNC metal cutting is used in a wide range of industries, including aerospace, automotive, medical device manufacturing, and electronics. In the aerospace industry, for example, CNC metal cutting is used to produce precision parts for aircraft engines and other components. In the medical device manufacturing industry, CNC metal cutting is used to produce complex parts for medical implants and devices.

CNC Metal Parts Machining Services

Are you in need of high-quality metal parts for your manufacturing process? Look no further than our CNC parts machining services. Our state-of-the-art equipment and experienced technicians can produce precision parts to your exact specifications.

At our machining facility, we offer a wide range of capabilities to meet your metal parts machining needs. Our services include CNC turning, CNC milling, CNC drilling, and CNC grinding. We use the latest technology and tools to ensure that our machining processes are efficient and accurate, resulting in high-quality parts every time.

Our team of experts works with a variety of materials, including aluminum, brass, copper, stainless steel, and titanium. We understand the unique properties and characteristics of each of these materials and can recommend the best options for your specific application.

We are committed to providing exceptional customer service and ensuring that your parts are delivered on time and to your satisfaction. Our team is dedicated to working closely with you throughout the entire machining process to ensure that we meet all of your requirements and exceed your expectations.

If you are looking for reliable and high-quality metal parts machining services, look no further than us. Contact us today to learn more about how we can assist with your metal parts machining needs.

FAQ

CNC metal cutting can be used to cut a wide range of materials, including steel, aluminum, copper, brass, and titanium.

CNC metal cutting is highly accurate, with tolerances as small as 0.001 inches possible.

Yes, CNC metal cutting can be used to create complex shapes and designs that would be difficult or impossible to achieve with traditional metal cutting methods.

Yes, CNC metal cutting is generally faster than traditional metal cutting methods, as the computer software can control the cutting process more precisely and quickly than a human operator.

CNC metal cutting is used in a wide range of industries, including aerospace, automotive, medical device manufacturing, and electronics.