CNC milling, or computerized numerical control milling, is a precision machining process that uses computerized controls to guide a milling machine tool. The cost of CNC milling can vary significantly depending on several important factors including:

Material

Harder materials like steel, aluminum, titanium, etc. typically cost substantially more to machine than softer materials like plastics, wood, or composites. Machining harder materials requires more durable cutting tools and slower feed rates, both of which increase cost. High-strength alloys or superalloys can cost 3-5 times more to machine than aluminum or plastics. Complex metal alloys or exotic materials can cost 10-50 times more to machine than basic steel or aluminum.

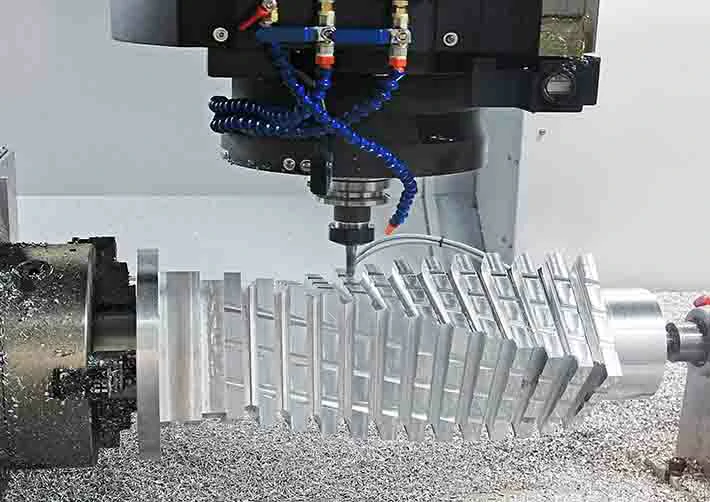

Part complexity

Simple parts with straight edges, flat surfaces, and minimal features will be the least expensive to produce. More complex parts with curved surfaces, pockets, slots, contours, threads, dies, molds, etc. require more programming and setup time and will cost significantly more, especially if tight tolerances are required. Complex mold inserts or die cast dies can easily cost $50,000-$200,000 or more. Parts with multiple surfaces, undercuts, islands, and intersecting contours can double or triple machining time and cost.

Quantity

For larger production runs, the fixed costs of programming and setup can be spread over more parts, resulting in lower unit costs due to economies of scale. High-volume production of complex parts can reduce costs by an order of magnitude compared to a single prototype. Long production runs of thousands, tens of thousands or hundreds of thousands of parts are required to achieve the lowest costs per part. Low-volume production will see little to no reduction in cost per part.

Machine tool

More advanced 5-axis milling machines with larger work envelopes, faster spindle speeds, higher power, increased precision, and extended tool storage will naturally cost substantially more to operate than smaller 3-axis mills. High-end 5-axis mills with 40-60 taper spindle bores, 12,000-15,000 RPM spindle speeds, 60-100kW of power, and high-accuracy components can cost $3,000-$10,000 per hour or more to run. More capable machines provide greater flexibility and capability but at a significantly higher hourly rate.

In summary, while CNC milling machining services provides precision and repeatability, the costs can be quite high. However, for many applications the benefits of CNC milling justify the investment. With a comprehensive understanding of the factors that influence cost, you can determine if CNC milling makes sense for your particular project, requirements, volume, and budget. The more complex the part, the harder the material, the more advanced the machine, and the lower the volume, the higher the cost of CNC machining will be. For simple parts, softer materials, smaller machines, and high-volume production, CNC milling can be a very affordable precision manufacturing process.