As the automotive industry continues to evolve, the use of CNC milling parts machining has become increasingly important. This manufacturing process offers numerous benefits over traditional manual machining methods, including increased accuracy and precision, improved efficiency, and reduced waste. In this article, we’ll explore the applications and advancements of CNC milling machining in the automotive industry.

CNC milling machining is used in a wide range of applications in the automotive industry, including:

1. Engine Components

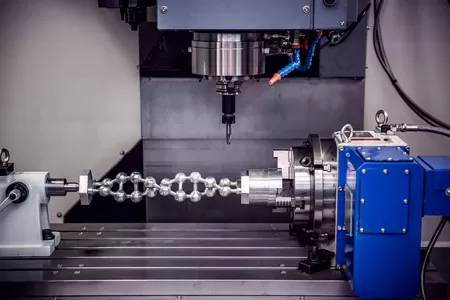

CNC milling machines are used to produce a variety of engine components, including cylinder heads, engine blocks, and crankshafts. These parts require a high degree of accuracy and precision, which CNC milling machines are able to provide.

2. Suspension Components

CNC milling machines are also used to produce suspension components, such as control arms, knuckles, and spindles. These parts require complex shapes and features, which CNC milling machines are able to produce with a high degree of accuracy and consistency.

3. Body and Interior Components

CNC milling machines are used to produce a variety of body and interior components, including door panels, dashboards, and center consoles. These parts require a high degree of customization and design flexibility, which CNC milling machines are able to provide.

Advancements in CNC Milling Machining for the Automotive Industry

CNC milling machining has continued to evolve and improve, with new advancements and technologies emerging all the time. Here are some of the latest advancements in CNC milling machining for the automotive industry:

1. Five-Axis Machining

Five-axis machining is a newer technology that allows for greater precision and flexibility in the production of complex parts. By using a five-axis CNC milling machine, manufacturers are able to produce parts with more complex shapes and features, resulting in higher quality and more customized products.

2. High-Speed Machining

High-speed machining is another technology that has emerged in recent years. This technology allows CNC milling machines to operate at higher speeds and produce parts at a faster rate than ever before. This results in improved efficiency and reduced production time, allowing manufacturers to produce parts more quickly and at a lower cost.

3. IoT Technology

IoT technology is becoming increasingly common in CNC milling machining, allowing manufacturers to monitor machine performance and identify potential issues before they become major problems. By using IoT technology, manufacturers can improve efficiency, reduce waste, and increase profitability.

4. Automation

Automation is another trend in CNC milling machining that is becoming increasingly popular. By automating certain tasks, such as loading and unloading workpieces, manufacturers can increase efficiency and reduce labor costs. Robotics can also improve safety by reducing the need for human operators to be in close proximity to the cutting tool.

Conclusion

CNC milling machining is a valuable tool in the automotive industry, offering numerous benefits over traditional manual machining methods. With its ability to produce high-quality and precise parts at a faster rate than ever before, CNC milling machining is helping manufacturers stay ahead of the competition and meet the demands of today’s automotive industry. By staying up-to-date with the latest advancements in CNC milling machining, manufacturers can continue to improve their production processes and achieve their production goals.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items