In the manufacturing industry, CNC precision parts are core components of many products, and their quality directly affects the performance and reliability of the final product. However, the processing of CNC precision parts is complex and involves multiple links. A little carelessness can lead to costly mistakes. This article will discuss how to avoid these mistakes based on specific cases and share experience in finding reliable suppliers.

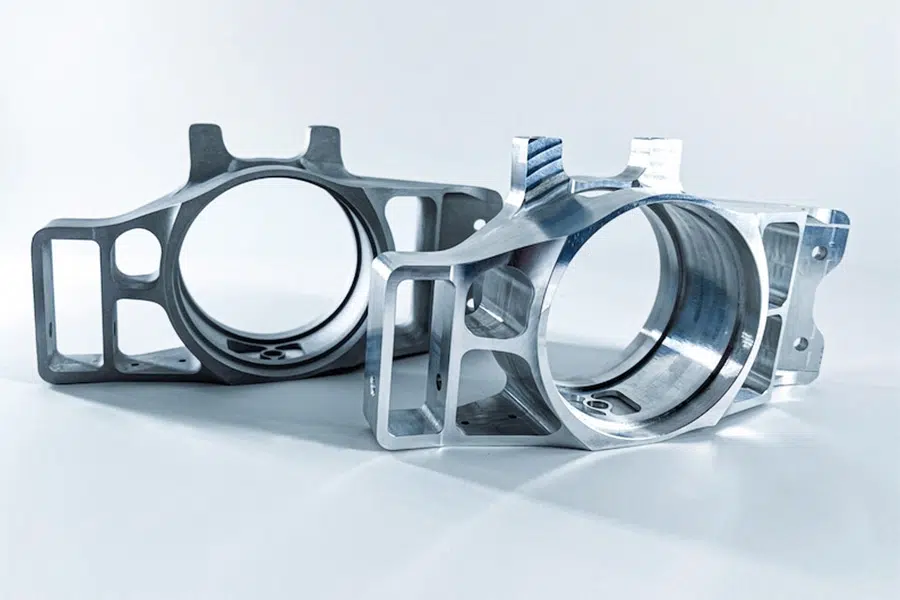

What Are CNC Machined Parts?

CNC (Computer Numerical Control) machined parts refer to parts that are automatically machined using computer numerical control technology and pre-programmed instructions to control machine tools. This machining method has the characteristics of high precision, high efficiency, high consistency and strong repeatability, and is widely used in various industrial fields.

1.Comparison of classification and standards

| Classify | Standard | Custom-made parts |

|---|---|---|

| Definition | It is produced according to a unified standard and has strong versatility | Designed according to specific needs, high uniqueness |

| Tolerance range | ±0.1mm (e.g. automotive engine mount) | ±0.01mm (e.g. aero turbine blades) |

| Application scenarios | Mass production (automobiles, home appliances) | High-precision requirements for small batches (aerospace) |

| Cost advantage | Large-scale production reduces costs | R&D and high cost per piece |

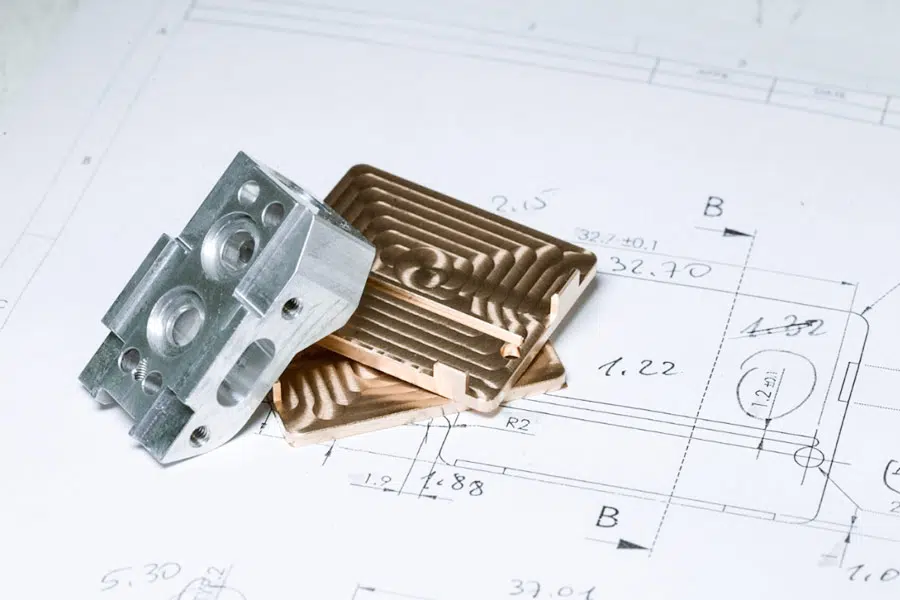

2. Material mapping and application scenarios

| Material | Typical grades | Core features | Preferred industry |

|---|---|---|---|

| Aluminum alloy | 6061-T6 | Lightweight, high-strength, and easy to process | Consumer electronics (mobile phone frame), structural parts |

| stainless steel | 316L | Corrosion-resistant, biocompatible | Medical equipment, chemical valves |

| PEEK | — | High temperature resistance 250°C, low friction | Aerospace seals, automotive engines |

3.Application scenarios and cost comparison

| Field | Typical parts | Core requirements: | Cost comparison between China and the United States |

|---|---|---|---|

| Consumer electronics | The middle frame of the phone | The batch size is large, and the accuracy ± 0.1mm | China:3.5/itemvsUnited States:8.2/pcs |

| Industrial equipment | Hydraulic valve block | The surface roughness is Ra0.8μm | The processing time has increased by 35% and the cost has increased significantly |

4. Design of cost estimation tools

CNC Part Cost Estimator (input material/tolerance/lot, real-time generation of quotation ranges for China, the United States and Europe)

Algorithm logic:

(1) Material cost:

based on the database of real-time market price (such as aluminum alloy 5/kg, PEEK80/kg).

(2) Processing cost:

Standard parts: tiered pricing by batch (e.g. 1-100 pieces: 10/piece; 1000+ pieces: 3/piece).

Customized parts: the cost increases by 15% for every ± 0.01mm of tolerance; Complex structures, such as surfaces, are billed extra.

(3) Regional differences:

China: Labor costs are low, but equipment depreciation is fast.

US/Europe: High labor costs, but high degree of automation.

(4) Volume discount:

For every 10 times increase in quantity, the unit price will be reduced by 20%.

Sample output:

Input:

Material = Aluminum alloy 6061, Tolerance = ±0.05mm, Lot size = 500 pieces

Output:

- China: $4.2-5.8/Piece

- United States: $7.5-9.3/piece

- Europe: $8.0-10.5/Piece

5.Industry Application Matrix:

- Automobile manufacturing: Used in the production of engine mounts, transmission parts, etc., requiring high precision and durability.

- Aerospace: used in the manufacture of turbine blades, structural parts, etc., with extremely high requirements for material properties and machining accuracy.

- Medical equipment: used in the production of surgical instruments, implants, etc., requiring material biocompatibility and processing precision.

- Consumer electronics: used in the production of mobile phone frames, laptop shells, etc., focusing on appearance quality and processing efficiency.

- Industrial equipment: used in the production of hydraulic valve blocks, pump bodies, etc., requiring surface roughness and machining accuracy.

Why 68% of CNC Projects Exceed Budget?

Going over budget is a common challenge faced by many businesses in CNC machining projects. According to statistics, up to 68% of CNC projects lead to cost overruns due to various reasons. These cost black holes not only affect the economic benefits of the project, but can also delay delivery times and even affect product quality. Don’t worry too much, LS will help you solve these problems and ensure that the project is delivered on time, with high quality, low cost and on-time.

Cost black hole 1: design flaws lead to scrapping

Case 1: A robot company lost $15,000 due to the deformation of thin walls (0.5mm) of aluminum parts

- Problem: The thin-walled structure in the design was deformed during machining, resulting in the scrapping of entire batches of parts.

- Cause: Insufficient force simulation and process optimization, design not in line with feasibility for manufacturability (DFM).

LS’s solution

- DFM Reports: LS provides detailed DFM reports during the project start-up phase, including force simulations and process optimization recommendations.

- Design optimization: It is recommended that the customer change the thin-walled structure to the stiffener design to ensure that there is no deformation during processing.

- The result: parts scrap avoided, $15,000 in cost savings, and the project was delivered on time.

Cost black hole 2: Failure caused by misselection of materials

Case 2: The corrosion rate of 304 stainless steel in the marine environment is 6 times higher than that of 316L, resulting in the replacement of parts of a ship in half a year

- Problem: 304 stainless steel lacks corrosion resistance in marine environments, resulting in frequent component failures.

- Cause: Failure to select the right material for the environment in which it will be used.

LS’s solution

- Material substitution: LS advised the customer to switch to 2205 duplex stainless steel, which increased the cost by 18% but extended the life by 3 times.

- Material Testing: Salt spray testing is carried out before mass production to ensure that the material meets the requirements of the marine environment.

- The result: a significant increase in part life and a 50% reduction in the customer’s total maintenance costs.

Cost black hole 3: unreasonable process leads to low efficiency

Case 3: An auto parts company extended the processing time by 40% due to unreasonable process

- Problem: The machining process is not optimized, resulting in low production efficiency and increased costs.

- Reason: Efficient processes such as high-speed cutting and multi-axis linkage are not used.

LS’s solution

- Process optimization: LS uses high-speed cutting technology and five-axis simultaneous machining to optimize the machining path.

- Equipment upgrade: the introduction of high-precision five-axis CNC machine tools to improve production efficiency.

- The result: a 40% reduction in processing time and a 25% reduction in total costs for the customer.

Cost black hole 4: supply chain mismanagement leads to delays

Case 4: An aerospace company delayed the project for 3 months due to a delay in delivery from a supplier

- Problem: Supplier delivery delays, resulting in delays in the overall schedule of the project.

- Reason: The supplier’s delivery capacity was not adequately assessed.

LS’s solution

- Supply Chain Management: LS has established a strict supply chain management system to ensure the on-time delivery of raw materials and parts.

- Alternatives: Provide customers with a list of alternative suppliers to ensure the stability of the supply chain.

- The result: the project was delivered on time and the client avoided additional costs due to delays.

Cost black hole 5: lax quality control leads to rework

Case 5: A medical device company reworked the whole batch due to the out-of-tolerance size of the parts

- Problem: The part size is out of tolerance, does not meet the design requirements, and leads to rework.

- Reason: Lack of rigorous quality testing.

LS’s solution

- Quality inspection: LS company introduced a coordinate measuring instrument and a surface roughness tester to monitor the processing quality in real time.

- Testing standards: ASME Y14.5 standards are used for testing to ensure that the parts meet the design requirements.

- The result: avoided rework and a 20% reduction in total costs for the customer.

Which CNC Supplier Type Fits Your Needs?

When it comes to custom CNC machining services, choosing the right supplier is key to a successful project. Different types of suppliers have their own advantages and disadvantages in terms of response speed, processing accuracy, cost and delivery stability. The following is an analysis of the characteristics of the three types of mainstream suppliers, combined with the advantages of LS Company, to help you choose the right supplier.

Local small and medium-sized processing plants

- Advantage:The response time is fast, and the quote is usually available within 24 hours, and it can quickly cooperate with urgent modifications. High flexibility for small batch production of non-critical components.

- Limitations:The machining accuracy is generally only up to IT8, which is difficult to meet the requirements of high precision. The equipment and technology are limited, and the ability to handle complex processes is insufficient.

- Price range:The rate of aluminum alloy equipment is about 25 – 50 yuan / hour, and the price is close to the people.

- Applicable scenarios:It is suitable for projects with low precision requirements, small production scale, and cost and time sensitivity, such as general product housings, simple bracket manufacturing.

Multinational manufacturing service provider

- Advantage:Provide a one-stop service, from 3D printing to post-processing. Global quality assurance, high delivery stability, suitable for industries with strict quality requirements.

- Cost:15% to 25% higher costs than regional suppliers, but 40% more consistent delivery.

- Case:A German company provides EMC compatibility testing to medical device customers to ensure that products meet international standards.

- Applicable scenarios:It is suitable for aerospace, medical equipment and other projects that require high precision and quality and sufficient budget.

Online CNC platform

- Innovation Highlights:With AI automatic quotation function, you can quickly get a quotation by uploading drawings, which is convenient and conducive to small and medium-sized enterprises and start-ups to find processing resources.

- Risk Warning:The platform commission is high, up to 18% – 30%, and the actual processor may subcontract multiple times to affect the quality, and the on-time delivery rate is only 78%.

- Applicable scenarios:It is suitable for projects with a small number of parts, low complexity, and low requirements for delivery time.

Supplier Scorecard

Based on the needs of the project, the following dimensions (sample weights) are scored for the supplier:

- Quality (40%): processing accuracy, quality inspection ability.

- Cost (30%): price competitiveness, cost performance.

- Communication efficiency (20%): response speed, technical support.

- Certifications (10%): Industry certifications (e.g. ISO 9001, AS9100).

Red Line List

- Suppliers without NC simulation software (such as VERICUT) are directly eliminated: lack of simulation capabilities may lead to processing failure or delay.

- Suppliers without strict quality control system are eliminated: the consistency and reliability of parts cannot be guaranteed.

How to Optimize CNC Precision Parts Sourcing?

Step 1: Design optimization

1. Unified aperture standards

- Strategy: Uniform bore size during the design phase to reduce the number of tool changes during machining.

- The result: 12% reduction in machining time, reduced tool wear and labor costs.

2. Replace right angles with rounded corners

- Strategy: Change the right angles in the design to rounded corners to reduce the stress concentration.

- The result: 1.8 times longer tool life, reduced tool replacement frequency and maintenance costs.

LS company case: Machining of connecting rods for an automobile

- Problem: The right angle in the original design led to frequent tool wear and high machining costs.

- Solution: LS proposed to change the right angle to a rounded corner and optimize the machining path.

- The result: a 1.8-fold increase in tool life and a 15% reduction in machining costs.

Step 2: Process Combination Strategy

1. 3D printing + CNC finishing

- Strategy: For complex structural parts, 3D printing is used to manufacture blanks, and then key parts are finished by CNC.

- Result: 28% lower cost than pure cutting process.

LS company case: UAV titanium alloy bracket

- Problem: Traditional CNC machining has high cost and long cycle.

- Solution: 3D printing is used to manufacture the blank, and then the key parts are finished by CNC.

- The result: a 28% reduction in machining costs and a 30% reduction in lead times.

Step 3: Geographic Sourcing Strategy

1. High precision demand: Japan/Germany

- Strategy: Choose suppliers from Japan or Germany to ensure high accuracy (roundness ≤ 0.001mm).

- Cost: Unit price $220/piece.

2. Cost sensitive: China/India

- Strategy: Choose suppliers in China or India to reduce costs.

- Cost: Unit price is $85/piece, delivery time is 14 days.

3. Regulatory sensitive: Nearshoring in Mexico

- Strategy: Select a Mexican supplier that meets USMCA regulatory requirements.

- Cost: 30% lower than U.S. domestic production.

LS case: A North American auto part

- Problem: Need to comply with USMCA regulations and be cost sensitive.

- Solution: LS recommended a Mexican supplier to provide nearshoring services.

- The result: 30% lower cost and 20% shorter lead time than domestic U.S. production.

Step 4: Bulk and segmented procurement

Strategy

- First order verification: The first 100 pieces are produced in China to verify the process and design feasibility.

- Expansion phase transfer: During the expansion phase, production will be transferred to a highly automated plant in Vietnam.

LS case

LS company divided the procurement of CNC precision parts into multiple batches according to the production plan and market demand forecast. The quantity of each batch purchased is determined according to the actual demand, which avoids the inventory backlog and capital occupation caused by excessive purchase.

Step 5: Intelligent production

Strategy

- Automation equipment integration: Deploy intelligent CNC machining centers and introduce robot-assisted production processes to realize the automation and intelligence of production links.

- Real-time monitoring and optimization: Build an online detection system, combined with data analysis tools, to carry out all-round real-time monitoring of the processing process, so as to adjust the production parameters in time.

LS case

LS implemented automation upgrades in the CNC shop, introduced robotic automation equipment, and provided CAM software. The robot can run stably for a long time, which significantly improves the production efficiency and processing accuracy. At the same time, the CAM software effectively shortens the machining time and reduces tool loss by optimizing the toolpath and machining parameters.

Step 6: Supplier cooperation and price comparison

CTA: Free submission of drawings for process optimization

- Strategy: After the customer submits the drawings, LS will provide three different routes for the customer to compare and choose from within 48 hours.

- Expected Result: The customer was able to clearly understand the differences in cost and efficiency between the different processes and thus select the optimal solution.

LS Company Case – A Medical Device Part

- Problem: The customer asked to optimize the processing process and reduce the production cost.

- Solution: LS compares three process routes and recommends the best option for the customer.

- The end result: a 25% reduction in machining costs and a 20% reduction in lead times.

Case: Aseptic processing of surgical instrument housings in the medical device industry

A medical device manufacturer plans to produce a batch of surgical instrument shells, which are made of medical-grade stainless steel. The product is in direct contact with the human body and requires extremely high quality requirements, meeting the standard of a surface finish of Ra≤0.2μm and meeting the requirements for aseptic processing.

Facing challenges

- High-precision machining problems: the dimensional accuracy of the product needs to be accurately controlled at ±0.01mm, and the surface roughness must reach Ra≤0.2μm.

- Aseptic manufacturing environment requirements: The production process must be carried out in a clean room and meet the ISO 13485 medical device quality management system certification standard.

- Tight delivery deadline: The project required the first prototypes to be delivered within 6 weeks.

Mistake Case: The Cost of Choosing an Unreliable Supplier

The manufacturer initially chose a small and medium-sized local processing plant. However, the supplier’s lack of aseptic processing experience and high-precision equipment led to a number of problems:

- Quality defects: The surface roughness of the product is not up to standard, and some parts have scratches and burrs.

- Delivery delays: Frequent rework delayed delivery times by 3 weeks.

- Cost overrun: Additional rework costs and urgent air freight costs were paid, resulting in a total cost overrun of 25%.

LS’s solution

1.Professional equipment and technical investment:

Five-axis CNC machine tools and special polishing equipment are used to ensure that the surface finish of the product reaches the standard of Ra≤0.2μm.

Production is carried out in a dust-free workshop, and aseptic processing standards are strictly followed.

2.Strict quality control system:

Coordinate measuring instrument and surface roughness detector are introduced to monitor the processing quality in real time.

ISO 13485 certified to ensure compliance with medical device industry standards.

3.Efficient delivery guarantee:

The production process was optimized, and the first prototypes were completed in just 4 weeks, 2 weeks ahead of schedule.

4.Presentation of results

- Quality standard: The dimensional accuracy and surface finish of all parts are fully in line with the requirements.

- On-time delivery: The project was completed on time and without any delays.

- Cost control is significant: With first-time, high-quality machining, rework and additional costs are avoided and total cost savings of 20 percent are achieved.

How to avoid costly mistakes?

- Choose suppliers with industry experience: Make sure the supplier is deeply familiar with the standards of the industry, such as ISO 13485 for the medical device industry and AS9100 for the aerospace industry.

- Verify the supplier’s equipment and technical capabilities: Carefully confirm whether the supplier is equipped with high-precision equipment, key equipment such as five-axis CNC machine tools, and CNC simulation software such as VERICUT to ensure processing accuracy and efficiency.

- Evaluate the quality control system: Carefully check whether the supplier has established a strict quality inspection process, such as using three-coordinate measurement, surface roughness inspection and other means to ensure stable and reliable product quality.

- Investigate delivery records and customer evaluations: Through detailed case analysis and real customer feedback, fully understand the supplier’s on-time delivery rate and its actual ability to deal with and solve problems.

Why choose LS?

LS is the best choice to avoid costly mistakes and ensure a successful project, based on the following benefits:

- Excellent high-precision machining ability: The machining accuracy can be accurate to ±0.005mm, which can fully meet the most stringent industry requirements and ensure that the product quality reaches the top level.

- Abundant industry solutions: We are well versed in the standards and needs of medical devices, aerospace, automotive and other industries, and can provide targeted and practical solutions according to the characteristics of different industries.

- Strict quality control: It has successfully passed a number of authoritative certifications such as ISO 9001, AS9100, ISO 13485, etc., to ensure the consistency and stability of product quality from the source to the end.

- Efficient delivery and cost control: The on-time delivery rate is as high as more than 95%, and at the same time, by optimizing the production process, it can save 20%-30% of the cost for customers, achieving a win-win situation of delivery efficiency and economic benefits.

- One-stop service experience: The business covers the whole process from design optimization to post-processing, providing customers with complete manufacturing solutions, effectively reducing communication costs, avoiding time waste, and improving the overall efficiency of the project.

Conclusion

In CNC precision parts processing, choosing a reliable supplier is the key to avoiding costly mistakes. LS has become an ideal partner for industries such as medical devices, aerospace, and automotive with its high-precision processing capabilities, strict quality control, industry-specific solutions, and efficient delivery.

Choosing LS is not only choosing a supplier, but also choosing a trustworthy partner. Contact us to start your journey of precision parts processing and ensure your project is delivered with high quality, low cost, and on time!

Contact us now to get exclusive CNC machining solutions!

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Pingback: What is the difference between CNC and laser cutting wood?