When it comes to precision manufacturing, there are a variety of techniques available. Two of the most popular options are CNC turning and CNC machining. Each method has its own benefits and drawbacks, making the choice between the two a difficult one. In this article, we will explore the differences between CNC turning and CNC machining to help you determine which option is better for your needs.

What is CNC Turning?

CNC turning is a process that involves using a lathe to shape a piece of material into a desired shape. The lathe spins the material while a cutting tool removes material to create the desired shape. CNC turning is ideal for creating cylindrical or round parts, and is often used to create parts for the automotive, aerospace, and medical industries.

One of the main benefits of CNC turning is its speed and efficiency when creating cylindrical parts. This makes it ideal for projects that require a large number of cylindrical parts to be produced quickly and accurately. CNC turning is also a more cost-effective option for smaller production runs, as it requires less setup time and can be completed more quickly than CNC machining.

Advantages of CNC Turning

CNC Turning (Computer Numerical Control Turning) is a modern machining process that has revolutionized the way components are produced. Here are some of the advantages of CNC Turning:

1. Precision:CNC Turning machines are highly accurate and can produce parts with very tight tolerances. This level of precision is difficult to achieve with manual machining processes.

2. Efficiency:CNC Turning machines can run continuously, 24 hours a day, with minimal supervision. This means that large quantities of components can be produced quickly and efficiently.

3. Versatility:CNC Turning machines can produce a wide range of components with varying complexities. They can be used to produce parts for industries such as aerospace, automotive, medical, and many others.

4. Consistency:CNC Turning machines are programmed to produce identical parts every time. This ensures that each component is of the same high quality and meets the required specifications.

5. Reduced Waste:CNC Turning machines produce very little waste material, as they are programmed to use the most efficient cutting paths. This reduces the amount of raw material required and minimizes waste.

In conclusion, CNC Turning offers many advantages over traditional machining processes. It provides a high level of precision, efficiency, versatility, consistency, and reduces waste. These benefits make CNC Turning a popular choice for the production of components across a wide range of industries.

What is CNC Machining?

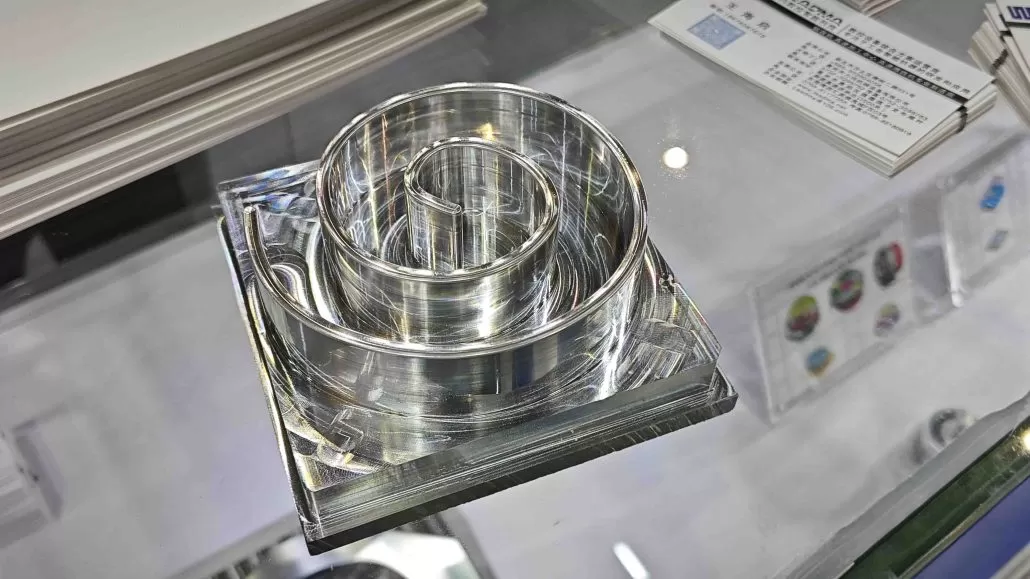

CNC machining, on the other hand, is a broader term that encompasses a variety of techniques used to remove material from a workpiece to create a desired shape. Unlike CNC turning, which is primarily used for cylindrical parts, CNC machining can be used to create parts of any shape. This makes it a more versatile option for precision manufacturing.

CNC machining is often used in the production of complex CNC machining parts that require high levels of precision and accuracy. This is due to the fact that CNC machining can create parts with tolerances as small as a few thousandths of an inch. CNC machining is also useful for creating parts with intricate designs and shapes that cannot be achieved using CNC turning.

Advantages of CNC Machining

Computer Numerical Control (CNC) is a modern manufacturing process that relies on computer software to control the operation of machinery. CNC machines offer a range of benefits over traditional machining techniques, including:

- Precision: CNC machines are highly accurate and can produce parts with exact dimensions and tight tolerances. This precision is achieved through the use of advanced software and high-quality cutting tools.

- Efficiency: CNC machines can work continuously for long periods of time without the need for human intervention. This means that they can produce parts much more quickly than traditional machining techniques.

- Consistency: CNC machines can produce identical parts with the same level of precision every time. This is particularly important in industries such as aerospace and medical device manufacturing, where consistency is critical.

- Versatility: CNC machines can be programmed to produce a wide range of complex parts, including those with intricate shapes and contours. This makes them ideal for producing custom or one-off parts.

- Safety: CNC machines are designed with operator safety in mind. They feature enclosed workspaces and safety interlocks to prevent accidents and injuries.

In conclusion, CNC machining offers a range of benefits over traditional machining techniques. These benefits include precision, efficiency, consistency, versatility, and safety. As a result, CNC machining has become an essential process in modern manufacturing.

Differences between CNC Turning and CNC Machining

One of the key differences between CNC turning and CNC machining is the type of parts that can be created. CNC turning is best suited for cylindrical parts, while CNC machining can be used to create parts of any shape. Additionally, CNC turning is typically faster and more efficient for creating cylindrical parts, while CNC machining can be slower but more precise.

Another important difference between the two methods is the cost. CNC turning is generally less expensive than precision CNC machining, making it a more cost-effective option for smaller production runs. However, CNC machining can be more cost-effective for larger production runs because it is more precise and can create parts more quickly.

Which Option is Better?

Ultimately, the choice between CNC turning and CNC machining depends on the specific needs of your project. If you need to create cylindrical parts quickly and cost-effectively, CNC turning may be the better option. However, if you need to create parts of varying shapes and require high precision, CNC machining may be the better choice.

In conclusion, both CNC turning and CNC machining are useful techniques for precision manufacturing. By understanding their differences, you can make an informed decision about which method is better for your specific needs. Whether you need to produce cylindrical parts quickly or create intricate parts with complex designs, there is a precision manufacturing technique that can meet your needs.