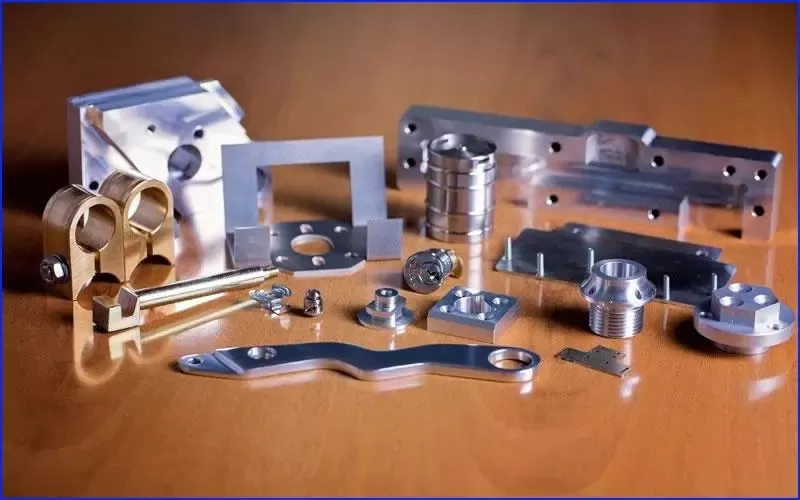

CNC machining is a universal manufacturing process that can be used to manufacture high-quality parts and components from various materials. Some of the most commonly used materials in CNC machining include:

Metals

Metals such as aluminum, brass, copper, and stainless steel are commonly used in online CNC machining due to their strength, durability, and resistance to corrosion. These materials can be machined to create parts and components with high precision and accuracy.

The following are common metal materials in CNC machining:

1.Steel: high hardness, high strength, suitable for manufacturing mechanical parts, auto parts and so on.

2.Aluminum: light weight, corrosion resistance, good thermal conductivity, suitable for manufacturing aircraft parts, auto parts, etc.

3.Magnesium alloy: light weight, high strength, wear resistance, suitable for manufacturing aircraft parts, automobile parts, etc.

4.Titanium alloy: light weight, high temperature resistance, corrosion resistance, suitable for manufacturing aircraft parts, medical equipment and so on.

5.Copper: good electrical conductivity, good thermal conductivity, suitable for manufacturing electrical and electronic products.

6.Iron: cheap, easy to process, suitable for the manufacture of building materials.

7.Stainless steel: corrosion resistant, beautiful and generous, suitable for manufacturing kitchenware, furniture, etc.

8.Alloy steel: high strength, wear resistance, pressure resistance, suitable for manufacturing chemical equipment, mechanical equipment and so on.

9.Aluminum alloy: light weight, high strength, corrosion resistance, suitable for manufacturing auto parts, motorcycle parts, etc.

10.Galvanized steel plate: corrosion resistant, suitable for manufacturing building materials, auto parts, etc.

11.Silicon steel plate: good magnetic permeability, suitable for manufacturing motors, transformers and so on.

12.Brass: corrosion resistant, suitable for manufacturing pipes, valves, etc.

13.Nickel alloy: high temperature resistance, corrosion resistance, suitable for manufacturing aircraft parts, oil refining equipment.

14.Manganese steel: high strength, good toughness, suitable for manufacturing machinery and equipment.

15.Cobalt-based alloy: high temperature resistance, corrosion resistance, suitable for manufacturing aircraft parts, oil refining equipment.

16.Titanium steel: light weight, high strength, high temperature resistance, corrosion resistance, suitable for manufacturing aircraft parts, medical equipment and so on.

17.Composite material: has the advantages of light weight, high strength, corrosion resistance, etc., suitable for manufacturing aircraft parts, sports equipment, etc.

18.Silver plated material: beautiful and generous, corrosion resistance, suitable for the manufacture of decorations.

19.Luoyang copper: long history, corrosion resistance, good electrical conductivity, suitable for the manufacture of high-grade pens, cigarette holders, etc.

20.Chrome plated material: beautiful and elegant, corrosion resistance, suitable for manufacturing automobile, motorcycle parts, etc.

21.Nickel-plated material: corrosion resistant, suitable for the manufacture of ornaments.

22.Boron alloy: high hardness, ductility, suitable for the manufacture of piano strings, auto parts, etc.

23.Tinning material: corrosion resistance, good electrical conductivity, suitable for manufacturing electronic products.

24.Red copper: good ductility, good conductivity, suitable for manufacturing pipes, electrical appliances, etc.

25.Rhodium alloy: high temperature resistance, corrosion resistance, suitable for the manufacture of catalysts.

26.Carbide: high hardness, wear resistance, suitable for manufacturing tools, molds and so on.

27.Gold-plated material: beautiful and generous, expensive, suitable for manufacturing high-end decorations.

28.Tungsten steel: high hardness, wear resistance, suitable for manufacturing tools, molds and so on.

29.Silver: good electrical conductivity, corrosion resistance, suitable for manufacturing electronic products, tableware, etc.

30.Cobalt molybdenum alloy: high strength, wear resistance, suitable for manufacturing high-speed cutting tools.

Plastics

Plastics such as acrylic, polycarbonate, and PVC are popular materials for CNC machining due to their low cost, lightweight, and easy machinability. These materials can be used to create a wide range of products, from simple prototypes to complex parts and components.

The following are common plastic materials used in CNC machining:

1.ABS

ABS is a commonly used plastic CNC material. It has the characteristics of high strength, good toughness, suitable for manufacturing toys, pipe fittings and so on.

2.PVC

PVC is a flexible plastic CNC material that does not burn easily. It is often used in the manufacture of cables, decorative materials, etc.

3.PE

PE is a flexible plastic CNC material, suitable for the manufacture of pump parts, seals and so on.

4.PP

PP is a low density plastic CNC material, suitable for the manufacture of tableware, medical equipment and so on.

5.PC

PC is a kind of impact resistant, transparent plastic CNC material, suitable for the manufacture of mobile phone shell, eyeglass lens and so on.

6.POM

POM is a kind of fatigue resistant, high hardness plastic CNC material, suitable for manufacturing bearings, gears, etc.

7.PA

PA is a kind of plastic CNC material with high strength, which is suitable for manufacturing mechanical parts, molds, etc.

8.PMMA

PMMA is a highly transparent plastic CNC material, suitable for manufacturing lamps, billboards, etc.

9.PTFE

PTFE is a corrosion-resistant, high-temperature resistant plastic CNC material, suitable for manufacturing chemical containers, pipe fittings, seals and so on.

10.PET

PET is a transparent plastic CNC material, suitable for the manufacture of food packaging, bottles and so on.

11.PBT

PBT is a kind of plastic CNC material with good insulation performance, which is suitable for manufacturing electrical parts and so on.

12.PPO

PPO is a kind of high temperature resistant, impact resistant plastic CNC material, suitable for manufacturing aviation parts, automotive parts and so on.

13.Nylon

Nylon is a flexible plastic CNC material, suitable for the manufacture of cables, mesh bags, etc.

14.ASA

ASA is a weather-resistant plastic CNC material, suitable for manufacturing outdoor products, billboards, etc.

15.PC/ABS

PC/ABS is a kind of plastic CNC material with high strength and good hardness, which is suitable for manufacturing laptop shell, mobile phone shell and so on.

16.PP-TD20

PP-TD20 is a plastic CNC material with high shrinkage rate, which is suitable for manufacturing lining plates in molds.

17.HIPS

HIPS is a kind of flexible plastic CNC material, suitable for manufacturing models.

18.PA6+GF

PA6+GF is a composite plastic CNC material with good wear resistance, suitable for manufacturing sliding parts.

19.PEEK

PEEK is a kind of plastic CNC material with high temperature and corrosion resistance, which is suitable for manufacturing high-end components such as aviation and automobiles.

20.PPS

PPS is a kind of plastic CNC material with good wear resistance and corrosion resistance, which is suitable for manufacturing chemical industry, medical industry and other fields.

21.TPU

TPU is an elastic plastic CNC material, suitable for manufacturing elastic bases and so on.

22.PTFE + BF

PTFE + BF is a kind of plastic CNC material with wear resistance and corrosion resistance, which is suitable for manufacturing chemical industry, medical industry and other fields.

23.POM + GF

POM + GF is a plastic CNC material with high strength and good hardness, suitable for manufacturing high-end mechanical parts.

24.PC + GF

PC + GF is a kind of plastic CNC material with impact resistance and high hardness, which is suitable for manufacturing automobile shell.

25.TPE

TPE is a flexible, non-toxic and tasteless plastic CNC material, suitable for the manufacture of children’s toys, medical equipment and so on.

26.PVC-U

PVC-U is a non-combustible plastic CNC material, suitable for manufacturing pipes and so on.

27.PC/ASA

PC/ASA is a weather-resistant plastic CNC material, suitable for manufacturing outdoor appliances, billboards, etc.

28.PVC-C

PVC-C is a kind of high temperature and corrosion resistant plastic CNC material, suitable for manufacturing chemical containers, pipe fittings and so on.

29.PP/EPDM

PP/EPDM is a kind of fatigue resistant, shock resistant plastic CNC material, suitable for manufacturing automotive parts and so on.

30.PVC-O

PVC-O is a kind of plastic CNC material with high strength and good flexibility, which is suitable for the manufacture of water supply pipelines and gas pipelines.

Ceramics

Ceramics are used in CNC machining to create parts and components that require high thermal and chemical resistance. These materials can be machined to create intricate designs and patterns, making them ideal for decorative items and other products.

30 common ceramic materials with slightly different uses and characteristics, allowing you to better understand them:

1.Tinmar glass ceramics: high temperature resistance, corrosion resistance, with good mechanical strength, widely used in aviation, aerospace and missile manufacturing.

2.Deutscher ceramics: With high hardness and high wear resistance, they can be used in the manufacture of cutting tools and bearings.

3.Alumina ceramics: resistant to high temperature and mechanical shock, can be used in the manufacture of circuit boards and thermistors.

4.Zirconia ceramics: With high hardness, high wear resistance and high bending strength, widely used in the manufacture of cutters and bearings.

5.Silicon boride ceramics: with high hardness, high wear resistance, high bending strength and high corrosion resistance, can be used in the manufacture of cutting tools and thermistors.

6.Boron nitride ceramics: With high hardness and high wear resistance, they can be used in the manufacture of cutting tools and abrades.

7.Silicon carbide ceramics: High temperature, high hardness and high wear resistance, can be used in the manufacture of cutting tools and bearings.

8.Ceramic composite: A combination of two or more ceramic materials commonly used to make high-pressure pumps, nozzles, and pneumatic valves.

9.Crystallized glass ceramics: resistant to high temperatures and mechanical shock, can be used in the manufacture of thermistors and heating elements.

10.Transparent ceramics: have good optical properties and can be used to manufacture pneumatic valves and optical components.

11.Magnetic ceramics: have good magnetic properties and can be used to make magnetic heads and electronic devices.

12.Titanium nitride ceramics: with high strength and toughness, it can be used to make composite materials and conductive ceramics.

13.Soft magnetic ceramics: have good magnetic and permeability, can be used to manufacture transformers and sensors.

14.Dielectric ceramics: have good electrical insulation properties, can be used in the manufacture of capacitors and high-frequency circuit components.

15.Hourglass ceramics: Their unique structure gives them excellent mechanical properties and can be used to manufacture filters and attenuators.

16.Spark plasma ceramics: with high wear resistance and high electrical conductivity, can be used in the manufacture of spark plugs and thermistors.

17.Boron carbide silicon nitride ceramics: Combine the advantages of both materials, with high hardness, high wear resistance and high bending strength.

18.Yttrium tetrooxide ceramics: with high insulation properties and high chemical resistance, can be used in the manufacture of capacitors and film capacitors.

19.Strontium titanate ceramics: have good dielectric properties, can be used to manufacture film capacitors and thermistors.

20.Ferroelectric ceramics: With high dielectric constant and piezoelectric effect, they can be used to make piezoelectric sensors and acoustic filters.

21.Stirling ceramics: Excellent performance at high temperatures, can be used in the manufacture of high temperature burners and high temperature reactors.

22.Titanium oxide ceramics: have good dielectric properties and piezoelectric effect, can be used to manufacture electroacoustic transducers and piezoelectric ceramic filters.

23.Magnesium oxide ceramics: have good heat resistance and corrosion resistance, can be used to manufacture high temperature reactors and catalysts.

24.Barium titanate ceramics: have good dielectric properties and good mechanical strength, can be used in the manufacture of film capacitors and high voltage capacitors.

25.Riboflavin ceramics: with high strength and toughness, it can be used to manufacture wear-resistant parts and ceramic balls.

26.High aluminum ceramics: have good wear resistance and corrosion resistance, can be used to manufacture abrasives and abrasives.

27.Aluminum nitride ceramics: With high hardness and wear resistance, can be used in the manufacture of cutting tools and abrasives.

28.Fluoride ceramics: with very high melting point and corrosion resistance, they can be used in the manufacture of high-temperature reactors and chemical equipment.

29.Heat conduction ceramics: have good heat conduction properties, can be used in the manufacture of radiators and electronic packages.

30.Alumina nitride ceramics: With high chemical stability and excellent corrosion resistance, they can be used in the manufacture of electrodes and electronic devices.

In conclusion, CNC machining can be used to create high-quality parts and components from a wide range of materials. When selecting a material for CNC machining, it is important to consider factors such as strength, durability, machinability, and cost to ensure that you choose the right material for your project.

Factors to Consider When Choosing Materials for CNC Machining

When selecting a material for CNC machining, there are several factors to consider:

Strength and Durability

The strength and durability of a material are important factors to consider when selecting a material for CNC machining. Choose a material that can withstand the forces and stresses that the finished product is likely to encounter during use.

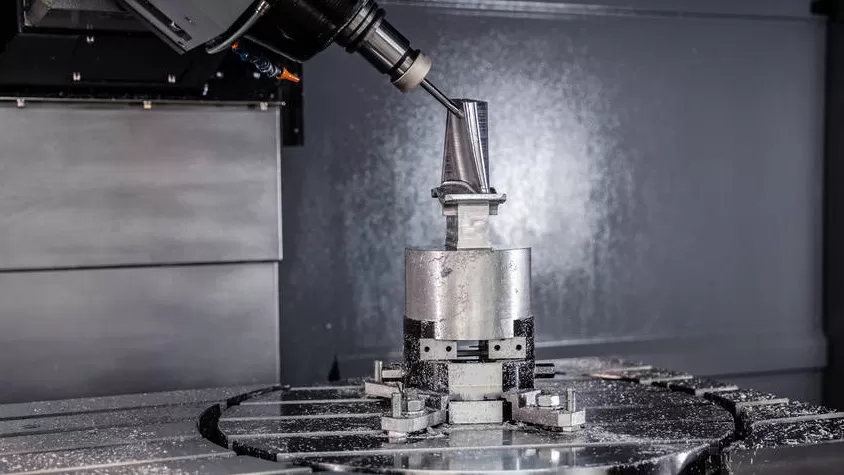

Machinability

The machinability of a material is another important factor to consider. Some materials are easier to machine than others, which can affect the cost and time required to produce the finished product. Choose a material that can be machined efficiently and accurately.

Cost

The cost of a material is an important consideration for any manufacturing project. Choose a material that fits within your budget and provides the required strength, durability, and other properties for the finished product.

Availability

The availability of a material is also an important consideration. Choose a material that is readily available and can be sourced easily to ensure that production can proceed smoothly.

Conclusion

CNC machining is a versatile manufacturing process that can be used to create high-quality parts and components from a wide range of materials. When selecting a material for CNC machining, it is important to consider factors such as strength, durability, machinability, cost, and availability to ensure that you choose the right material for your project. By selecting the right material, you can ensure that your finished product meets your requirements for quality, durability, and performance.