The Die Casting Process

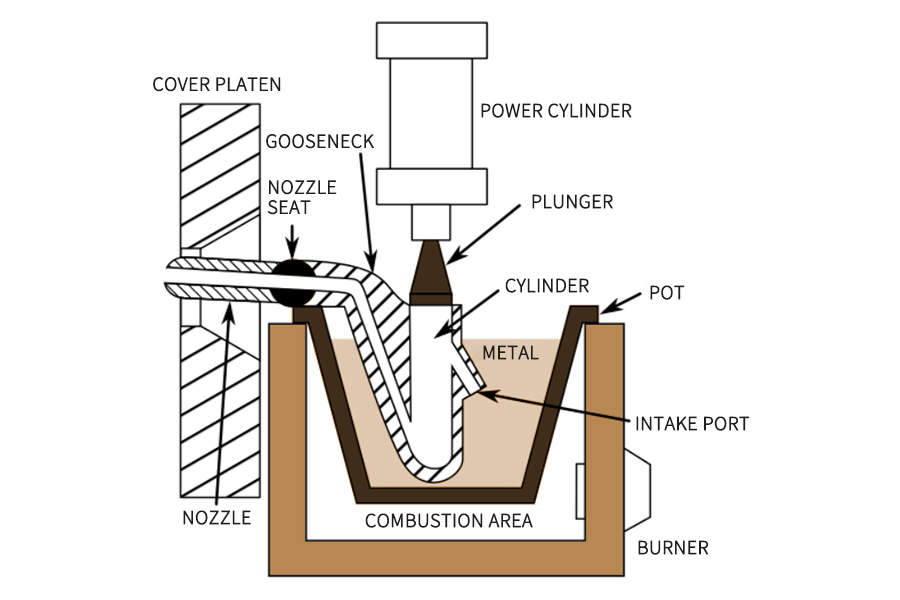

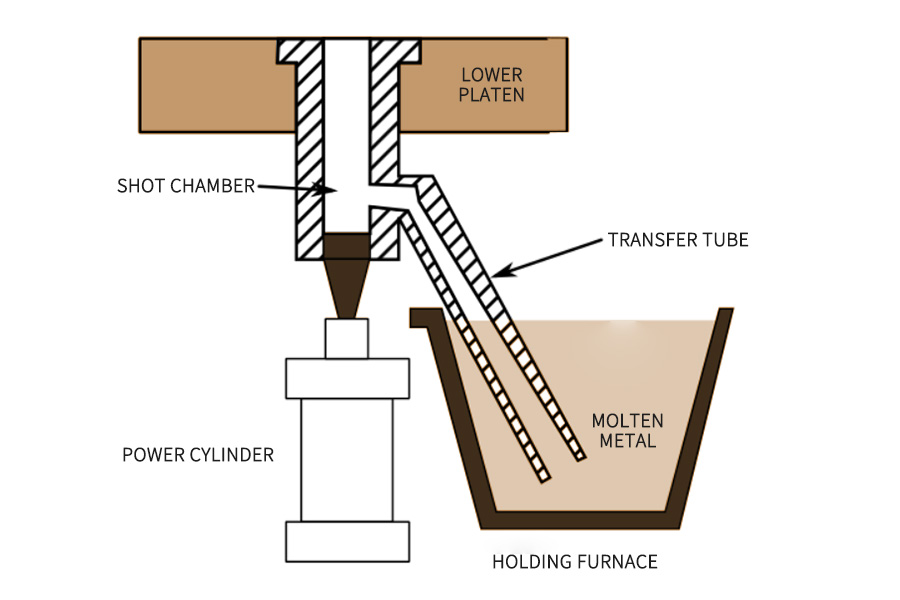

Die casting is a high-pressure steel casting process that entails forcing molten steel right into a mold cavity. The process is thought for producing parts with excessive uniformity, good floor end, and excessive dimensional accuracy. There are two fundamental sorts of die casting: scorching chamber and chilly chamber. Sizzling chamber die casting is appropriate for metals with decrease melting factors resembling zinc, magnesium, and sure aluminum alloys, whereas chilly chamber die casting is used for metals like aluminum which have increased melting factors.

Materials Utilized in Die Casting

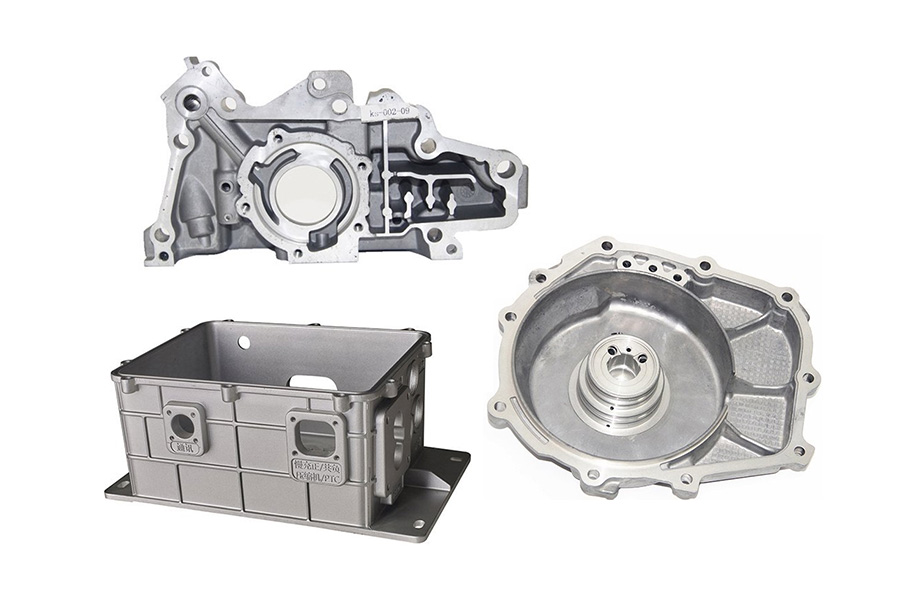

Frequent supplies utilized in die casting embody non-ferrous metals resembling aluminum, magnesium, and zinc. Aluminum is light-weight and corrosion-resistant, making it a well-liked selection for automotive parts. Magnesium gives advantages as a consequence of its lighter weight in comparison with aluminum and metal. Zinc is favored for its capability to offer clean floor finishes and tight tolerances.

Advantages of Die Casting

Die casting gives a number of benefits, together with excessive effectivity, wonderful dimensional accuracy, and the flexibility to provide advanced thin-walled castings. The process additionally permits for quick manufacturing cycle instances and a discount in materials scrap. Die solid parts can have quite a lot of floor textures and finishes, and the process is economical for mass manufacturing because of the lengthy instrument life, particularly for zinc and magnesium.

Limitations and Disadvantages of Die Casting

Regardless of its benefits, die casting has some limitations. It’s only appropriate for non-ferrous metals, requires a excessive preliminary funding, and is vulnerable to defects resembling porosity. The process is usually not appropriate for small initiatives as a consequence of the price of dies and tools. Moreover, die life will be low when casting excessive melting level alloys, and the process will be labor-intensive.

Software of die casting

| Business | Functions |

|---|---|

| Automotive | Engine blocks, gearboxes, stators, brackets, digital covers, sunroof parts, seatbelt parts, chassis parts, transmission parts, automobile inside parts, air-conditioning techniques, engine parts, brake techniques, energy steering techniques, gasoline consumption parts |

| Electronics | Enclosures for digital gadgets, warmth sinks, connectors, terminal blocks, chassis, frames, bases, mounting plates, covers, doorways, brackets, helps, cable glands, handles, knobs, bezels |

| Aerospace | Plane parts |

| Renewable Power | Energy technology and distribution tools |

| Agricultural | Parts for equipment resembling mix harvesters and tractors |

| Leisure Tools | Numerous leisure tools and automobile parts |

| Army/Protection | Components for legislation enforcement, business, and navy functions |

| Industrial Equipment & Tools | A number of parts of apparatus and techniques |

| Medical | Implantable gadgets, surgical devices, numerous tools parts |

| Shopper Merchandise | Family home equipment, energy instruments, digital gadgets |

The Investment Casting Process

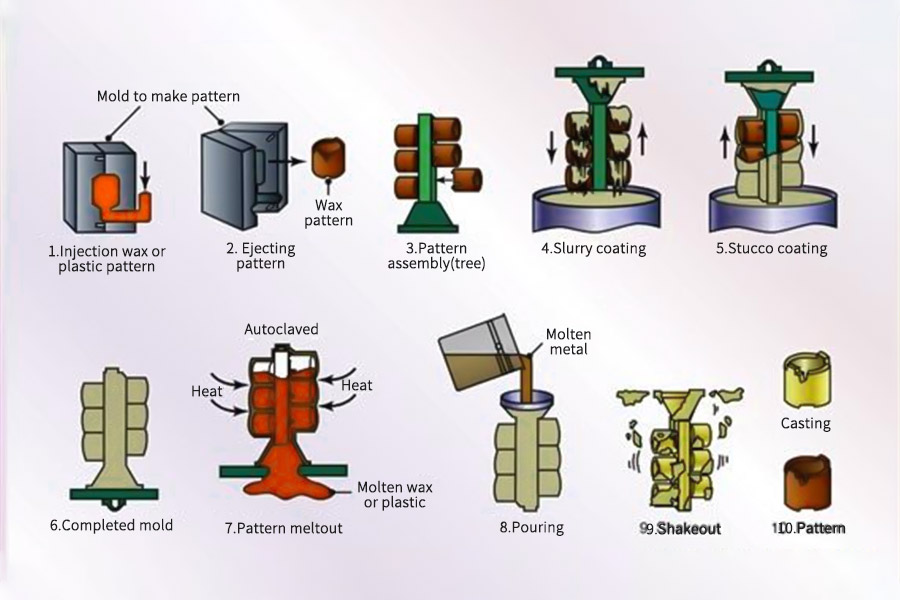

Funding casting entails making a wax sample, which is a precise duplicate of the specified half. This sample is then coated with a refractory ceramic materials to kind a ceramic shell. After the ceramic shell dries, the wax is melted out, leaving a hole mold. Molten steel is poured into this ceramic mold to kind the casting part. As soon as the steel solidifies, the ceramic mold is eliminated, revealing the ultimate steel half. Some castings might require secondary machining or ending processes.

Materials Appropriate for Investment Casting

A variety of supplies can be utilized in investment casting, together with numerous metals and alloys resembling stainless-steel, brass, aluminum, carbon metal, and even glass. Every materials gives totally different properties:

- Carbon Metal: Excessive structural integrity, particularly when heat-treated .

- Aluminum Alloys: Broad class with altered properties for toughness and machinability.

- Stainless Metal Alloys: Completely different casting traits, typically chosen for corrosion resistance.

- Brass: Used for each practical and ornamental functions as a consequence of its versatility and corrosion resistance.

- Nickel and Cobalt Alloys: Recognized for distinctive warmth growth properties and magnetic traits, appropriate for high-temperature functions .

- Tremendous Alloys: Present excessive rigidity and superior service traits, typically utilized in aerospace and vitality sectors.

- Copper Alloy: Corrosion-resistant, utilized in marine and electrical parts.

- Forged Iron: Recognized for prime accuracy and affordability.

Advantages of Investment Casting

Funding casting is favored for its capability to provide parts with excessive dimensional accuracy, intricate particulars, and superb floor finishes. The process permits for the creation of advanced shapes, inside cavities, and skinny partitions which can be tough to realize with different casting strategies. It additionally gives good dimensional accuracy and repeatability, distinctive floor high quality, and the flexibility to consolidate advanced assemblies right into a single solid half. Tooling prices are comparatively low in comparison with die casting, and there may be much less materials wastage as feed and sprue parts will be reused. Funding casting may also produce parts with the identical properties because the uncooked materials used.

Limitations and Disadvantages of Investment Casting

Regardless of its many benefits, investment casting has some limitations. It’s typically extra pricey than different casting strategies, particularly for short-run productions. The process will be difficult because of the many steps concerned, which leaves a large scope for error. There are additionally measurement and weight limitations for the solid parts, and the per-component value is increased than for sand casting on the one-off degree. Materials limitations have to be thought-about, though they don’t seem to be vital.

Software of Investment Casting

| Business | Functions |

|---|---|

| Aerospace | Turbine blades, airplane parts that want to resist excessive temperatures |

| Energy Era | Parts for energy technology tools |

| Firearm | Components with advanced geometry |

| Automotive | Excessive-temperature parts |

| Army | Numerous parts for navy functions |

| Business | Numerous business functions |

| Meals Service | Numerous parts for meals service tools |

| Gasoline and Oil | Parts for gasoline and oil business |

| Power | Parts for vitality business |

| Medical | Surgical devices, implantable gadgets |

Investment Casting Companies at LongSheng

At LongSheng, we’re a premier supplier of investment casting providers. Outfitted with years of business expertise and state-of-the-art manufacturing tools, we’ve the information, expertise, and instruments to provide high quality solid parts and merchandise appropriate to be used in even probably the most crucial industrial functions.To study extra concerning the variations between investment casting and die casting or our providers and capabilities, attain out to us immediately.Comparability of Die Casting and Investment Casting

| Parameter | Die Casting | Investment Casting |

|---|---|---|

| Design and Complexity | Appropriate for parts with intricate designs, skinny partitions, undercuts, and tight tolerances. Nevertheless, can’t produce as advanced parts as investment casting. | Provides better design flexibility, can solid advanced shapes, obtain exact dimensions, advanced geometries, and thin-walled parts. |

| Manufacturing Quantity and Price-Effectiveness | More cost effective for high-volume manufacturing runs. Increased volumes result in decrease per-unit prices as a consequence of economies of scale. | Costlier as a consequence of its extremely handbook process. Nevertheless, it may be cost-efficient for high-volume runs. |

| Dimensional Accuracy and Floor End | Produces parts with good dimensional accuracy and floor end. The smaller the casting, the better the dimensional accuracy. | Delivers superior dimensional accuracy and wonderful floor finishes. |

| Mould Utilization and Reusability | Molds in die casting are sometimes designed for long-term use, which might offset the preliminary excessive value over time. | Every distinctive casting run requires a brand new die to provide wax patterns. The wax used can often be recovered for reuse. |

Selecting the Proper Process for Your Software

Concerns for Small vs. Giant Manufacturing Runs

For small manufacturing runs, sometimes outlined as 50 to tens of 1000’s of items, strategies like CNC machining, Carbon’s Digital Gentle Synthesis™ (DLS), and investment casting are appropriate as a consequence of their pace and suppleness for extremely custom-made parts and prototypes. Multi-Tasking machines, initially developed for low lot sizes, can deal with simultaneous operations and are helpful for small to medium volumes. For bigger manufacturing runs, die casting and movement manufacturing strategies are extra acceptable as a consequence of their financial advantages and suitability for high-volume initiatives.

Structural Integrity and Mechanical Properties

Die casting produces merchandise with good structural integrity and mechanical properties because of the excessive strain utilized to the molten steel within the mold cavity. Funding casting is thought for its capability to carry substantial tolerances and create parts with superior dimensional accuracy and floor finishes. Forging, in comparison with casting, gives superior power and put on resistance, making it a greater choice if structural integrity is a major concern.

Price Implications and Quantity Breakpoints

The price-effectiveness of a producing process is influenced by manufacturing quantity, with die casting being cheaper for big portions as a consequence of its low unit value per piece. Funding casting will be extra cost-efficient for smaller manufacturing runs as it might cut back or keep away from secondary machining.

Which Process Is Right for Your Project?

No two casting projects are the same and with different projects, there are different solutions. Here are a few things to consider before you start your next project to help you choose which process is right for your component.Material Selection

Most die cast parts are made from non-ferrous metals like zinc, aluminum, and magnesium. Investment casting is capable of casting cast those metals along with ferrous metals, including stainless steel. If you are looking to use a non-ferrous material, both processes offer comparable features. However, if you are looking to use stainless steels or copper alloys, investment casting is the better option.Annual Volume

When deciding which casting process to use, decide what your desired payback period is for the tool cost. How many parts created versus the cost of the tooling to “break even.” While investment casting tooling may be cheaper and suitable for lower volume projects, die casting is ideal for larger production runs and high-volume projects.Tolerance

With any casting process, tolerance capabilities are largely influenced by the shape of the part and the type of material used. The table below compares general linear tolerances for conventional die casting and investment casting. The multi-slide die casting process is capable of holding even tighter tolerances.| DIMENSIONAL TOLERANCE COMPARISON | ||

|---|---|---|

| Die Casting | Investment Casting | |

| Up to 25mm | +/- 0.050mm | +/- 0.250mm |

| Up to 50mm | +/- 0.075mm | +/- 0.350mm |

| Up to 75mm | +/- .0.100mm | +/- 0.400mm |

| Up to 100mm | +/- 0.125mm | +/- 0.500mm |

| **Please allow up to 0.025mm for each additional 25mm |

Cycle Time

While investment casting and die casting both produce complex parts, the cycle times differ greatly. Traditional investment casting is a timely process that requires quite a bit of labor and hours of work, while die casting can produce 3-4 shots per minute for conventional die casting and upwards of 45 shots per minute with multi-slide die casting. A die cast part can often times be created without the touch of a human hand—complete automation!Cost

Cycle time determines up to 60% of your final part cost so it is no surprise here, that per part, investment casting generally costs more than die casting. Its highly manual processes yield parts very similar to that of a die casting, but the cycle time is much longer.When casting in high volume, die casting is more cost effective than investment casting. If you are casting only a few parts or require larger size or stainless steel, investment casting may be the lower cost option.While both investment casting and die casting create parts with comparable features, when extremely high-volume manufacturing is desired, the associated costs and longer cycle times can make investment casting a less-suitable option depending on your needs and deadlines. It is best to speak with an experienced casting engineer to determine which casting process is best suited for your next project—contact our team today!Resource

FAQs

What’s the special casting process?

The special casting process refers to a set of superior and specialised methods used within the manufacturing business to provide intricate and high-quality steel parts. These processes typically contain distinctive strategies and applied sciences tailor-made to particular casting necessities. Some examples of special casting processes embody:

Centrifugal Casting: Makes use of centrifugal forces to distribute molten steel inside a spinning die, ensuing within the manufacturing of cylindrical parts with excessive structural integrity and floor end. This technique is appropriate for mass manufacturing and can be utilized for non-ferrous supplies.

Investment Casting: Recognized for its capability to provide extremely detailed and complicated parts with distinctive dimensional accuracy and floor end. It’s generally used for precision tools, advanced geometries, and valuable metals.

Shell-Mould Casting: Entails the usage of a skinny shell made from sand held collectively by a thermosetting resin binder. This process yields higher floor high quality and tolerances and is appropriate for producing intricate parts.

Die Casting: Makes use of excessive strain to provide parts with good structural integrity and mechanical properties. It’s sometimes used for high-volume manufacturing runs and will be appropriate for each non-ferrous and ferrous supplies.

What’s the most typical kind of casting?

What’s an instance of casting?

An instance of casting will be discovered within the process of investment casting. This specialised casting technique entails the creation of intricate and detailed steel parts via the usage of a wax sample. The process begins with the manufacturing of a wax sample, which is then coated with a ceramic materials to kind a mold. As soon as the mold is about, the wax is melted or burned out, forsaking a cavity within the form of the specified half. Molten steel is then poured into the cavity, creating the ultimate steel part.

Funding casting is often used to provide parts with advanced geometries, intricate particulars, and superior floor finishes. It’s a versatile process that may be utilized for a variety of functions, together with aerospace parts, jewellery, and medical tools. The precision and intricacy achievable via investment casting make it a chief instance of the capabilities of casting processes in manufacturing.

I sincerely enjoyed what you have produced here. The design is refined, your authored material trendy, yet you appear to have obtained a degree of apprehension regarding what you aim to offer next. Certainly, I shall return more frequently, just as I have been doing almost constantly, provided you uphold this incline.

The sense of community your blog fosters is truly remarkable.