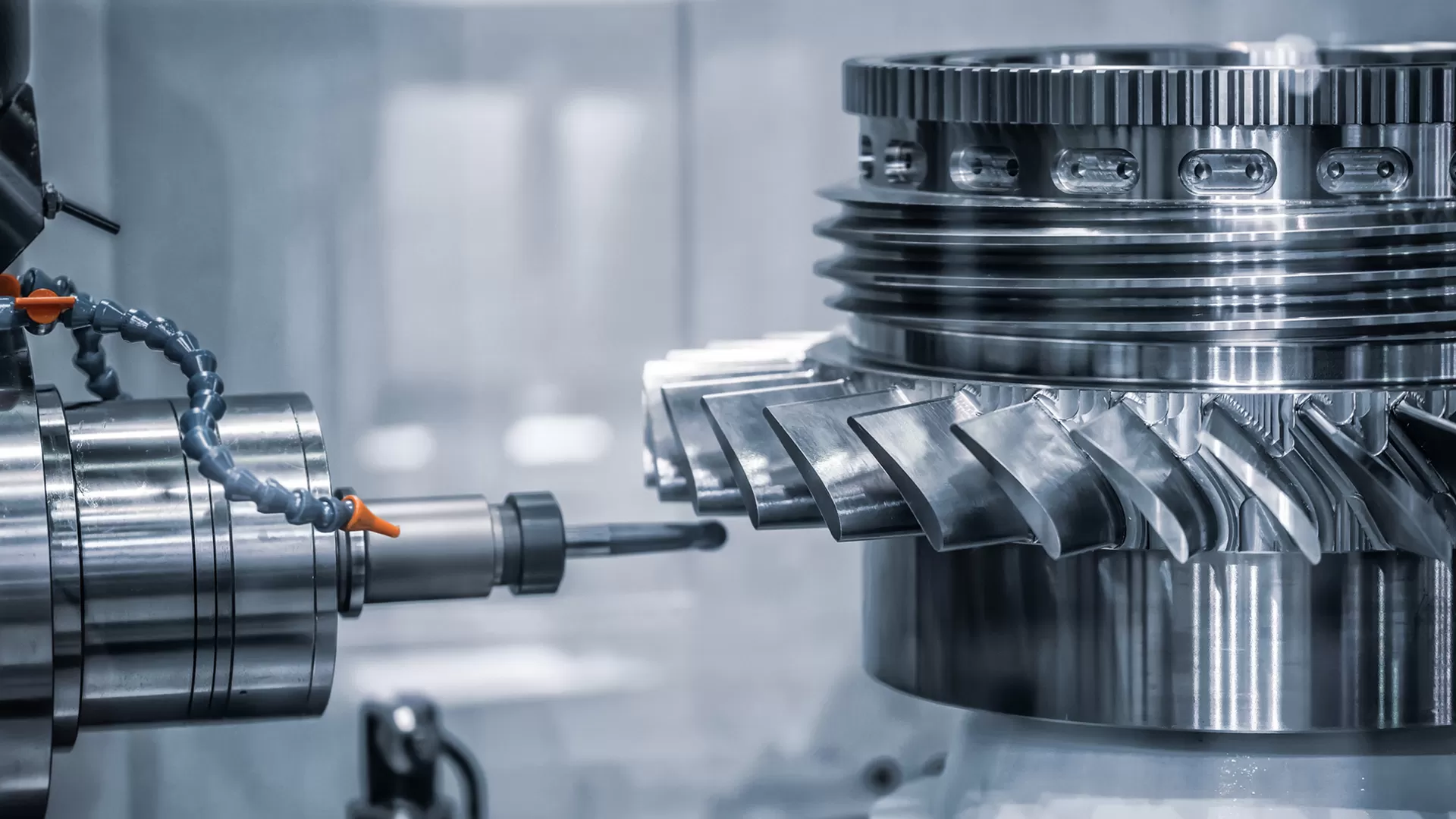

CNC machining is a cutting process that utilizes computer numerical control (CNC) technology to precisely cut an object or part to the desired shape and size. This machining process is used in many different industries such as automotive, aerospace, healthcare, and manufacturing. CNC machining is widely used because of its accurate results, cost-effective nature, and ability to create complex parts with high precision and repeatability.

The materials used in CNC machining are just as important as the process itself. There are many different types of materials that can be used depending on the application, including metals, plastics, composites, and even ceramics. Each material has unique characteristics that make it ideal for a particular purpose, so the choice of material should be carefully considered when designing a part or product. In this article, we will discuss the different materials used in CNC machining and their best applications.

Metals

Metals are one of the most popular materials used in CNC machining, as they are strong, durable, and relatively inexpensive. Commonly machined metals include aluminum, brass, bronze, copper, steel, and titanium. These metals can be machined to exact specifications for a variety of products, such as aircraft and automotive components, mechanical parts, medical devices, and much more.

Aluminum is lightweight and easy to work with. It is a popular choice for aerospace and automotive components due to its strength and resistance to corrosion. Brass is often used for plumbing fixtures and decorative components due to its malleability and pliability. Bronze is a strong metal that is resistant to wear and corrosion, making it suitable for gears, pumps, and valves. Copper is electrically conductive and can be used for electrical components, connectors, and wires. Steel is strong and typically used for structural components and machine parts. Titanium is lightweight yet strong and can be used for aircraft and automotive components.

Plastics

Plastics are often used for prototyping and for smaller scale applications in the production of parts and products. They are lightweight and come in a wide variety of shapes, colors, and textures. Commonly used plastics in CNC machining include acetal, acrylic, polycarbonate, polyethylene, and polypropylene. They can be machined to exact specifications and often require no post-processing. Plastics are versatile and can be used in a variety of applications, such as medical and electronic components, packaging, and toys.

Composites

Composites are materials composed of two or more different elements. They are often used for high-performance parts and components that require greater strength, durability, and low weight. Common composite materials used in CNC machining include carbon fiber, glass fiber, and Kevlar. They are often used for aerospace and automotive components, sporting goods, and tools.

Ceramics

Ceramics are non-metallic materials composed of metallic oxides. Commonly machined ceramics include alumina, boron nitride, silicon nitride, and zirconia. Ceramics are very hard and durable, and often used for high temperature components and wear-resistant parts and products. Some common applications include aerospace components, cookware, and dental implants.

Conclusion

CNC machining is a great way to create parts and products with accuracy, repeatability, and affordability. Choosing the right material is key to getting the desired outcome. Metals, plastics, composites, and ceramics are all popular materials used in CNC machining, and each has its own unique characteristics that make it great for certain applications. Consider the application and the desired outcome before selecting a material for CNC machining.

Related product processing customized services:

CNC Machine Parts Manufacturer

CNC Milling Parts Machining Service

High -Precision CNC Turning Machine Parts

Sheet Metal Machining Parts Center

Pingback: Custom CNC Parts for Industrial Machinery | Plastic CNC Machining Custom