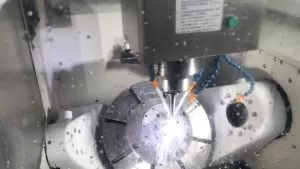

CNC turning is a form of machining that is used to create cylindrical parts. The process involves the use of a lathe, which is a machine that rotates a workpiece while cutting tools are used to remove material to shape it. There are many different types of lathe tools that can be used in CNC turning, and each has its own purpose and advantages. In this blog post, we will explore some of the most common lathe tools and their applications.

What is a Lathe?

A lathe is a tool that rotates a workpiece while a cutting tool removes material from it, shaping it into the desired form. Lathes can be used to create objects of all shapes and sizes, from small components to large pieces such as bowls and vases.

There are many different types of lathes, each designed for specific purposes. The most common type of lathe is the woodworking lathe, which is used to create turned wood products such as furniture legs and table bases. Metalworking lathes are also widely used, and these machines can create everything from metal pipes to engine parts.

CNC turning is a type of machining that uses computer numerical control (CNC) to automate the process of creating turned parts. CNC lathes have replaced traditional manual lathes in many manufacturing settings, as they provide greater precision and repeatability. CNC turning can be used to create both simple and complex parts, making it ideal for a wide range of applications.

The Different Types of Lathes

There are several different types of lathes that can be used in CNC turning. The type of lathe that is best for a particular application depends on the material being turned, the size and shape of the workpiece, and the desired finish.

The most common type of lathe is the engine lathe. Engine lathes are capable of turning large workpieces with a high degree of accuracy. They are typically used for heavy-duty machining applications such as turning shafts, gears, and other large components.

Another type of lathe that is commonly used in CNC turning is the turret lathe. Turret lathes are similar to engine lathes but have a turret instead of a headstock. This allows for more versatility when machining complex parts with multiple sides.

CNC Swiss-type lathes are another option that can be used for CNC turning. These lathes are designed specifically for small, precision parts. They use live tooling to allow for machining operations on multiple sides of the workpiece simultaneously.

Finally, there are also specialty lathes that are designed for specific materials or applications. For example, there are woodturning lathes that are designed specifically for turning wooden objects such as bowls and table legs.

CNC Turning

CNC turning is a process that uses computer numerically controlled (CNC) machinery to create turned parts. In CNC turning, the workpiece is held in a chuck and rotated while a cutting tool is fed to the workpiece to remove material.

CNC turning can be performed on a variety of materials, including metals, plastics, and composites. The type of cutting tool used will vary depending on the material being machined.

Common cutting tools used in CNC turning include:

Carbide inserts: Carbide inserts are made of carbide, an extremely hard material that can withstand high temperatures and speeds. Carbide inserts are available in a variety of shapes and sizes to suit different applications.

High-speed steel (HSS) tools: HSS tools are made of steel that has been hardened for use at high speeds. HSS tools are less brittle than carbide inserts and can be used on a wider range of materials.

Ceramic inserts: Ceramic inserts are made of alumina or silicon nitride, two materials that are harder than carbide or HSS. Ceramic inserts are well suited for machining difficult-to-machine materials such as titanium alloys or stainless steel.

What are the Different Types of Lathe Tools?

There are four main types of lathe tools: cutting tools, turning tools, boring tools, and facing tools.

Cutting tools are used to remove material from the workpiece. The most common type of cutting tool is the single-point cutting tool, which has a sharp point that is used to cut into the workpiece. Turning tools are used to create cylindrical shapes by removing material from the outside or inside of the workpiece. Boring tools are used to create holes in the workpiece. Facing tools are used to create flat surfaces on the workpiece.

How to Use Lathe Tools

To use a lathe tool, first, identify the workpiece and determine the appropriate tool. If you are working with wood, for example, you will need a different tool than if you are working with metal. Once you have selected the appropriate tool, position it in the lathe so that it is parallel to the workpiece. Next, turn on the lathe and slowly bring the tool into contact with the workpiece. Apply pressure to the tool as needed to shape the workpiece. Finally, turn off the lathe and remove the tool from the workpiece.

Conclusion

CNC turning is a process that can be used to create a wide variety of parts and products. In order to be successful, it is important to have the right tools for the job. In this article, we have looked at some of the different types of lathe tools that can be used in CNC turning. We hope that this information has been helpful and that you will now be able to choose the right tool for your next project.