LONGSHENG

Instant extrusion moulding parts online quotes

Lead Time as Fast as 1 Day

Get your custom parts at low prices

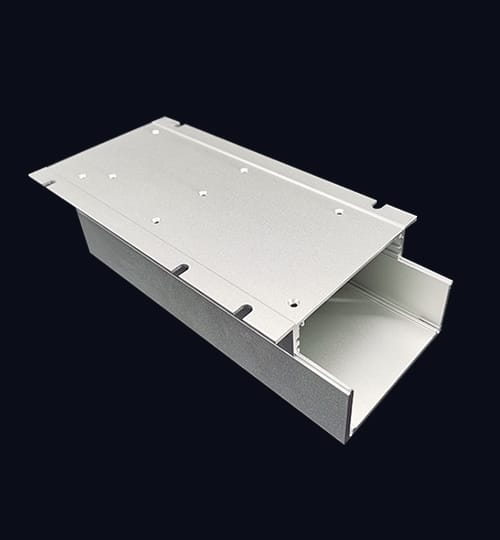

Customized Extrusion Moulding Parts Service

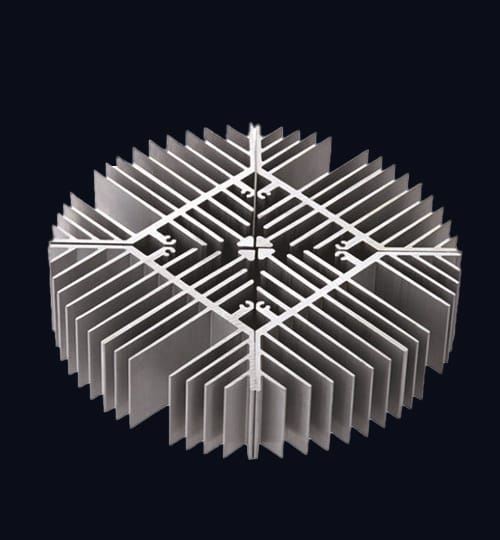

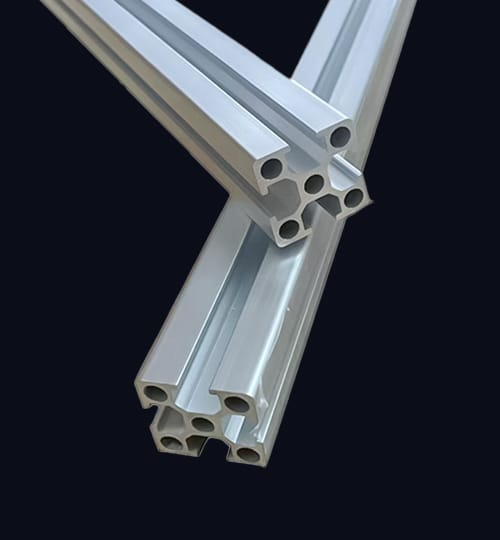

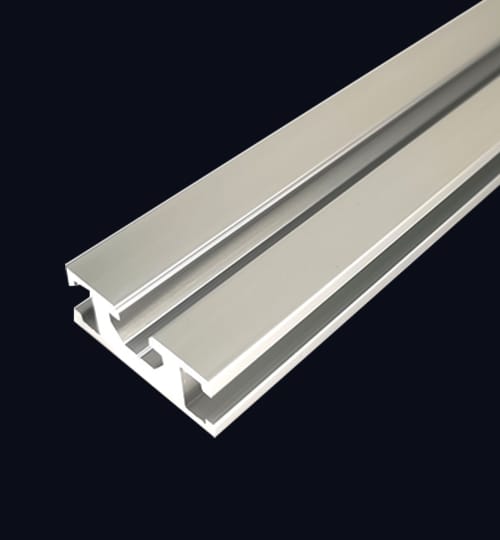

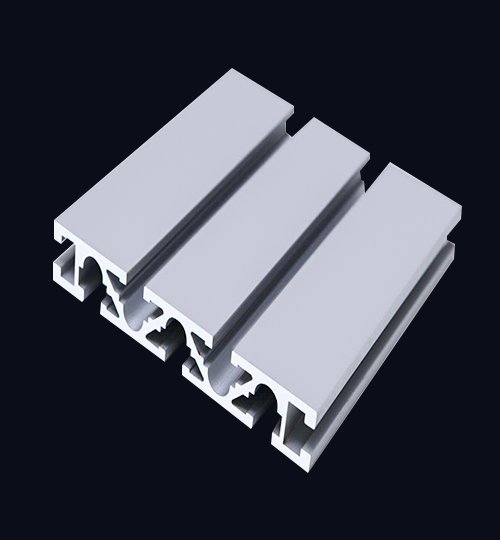

We offer a customized extrusion moulding parts service to meet your specific needs. Our team of experts can work with you to design and produce high-quality parts that meet your exact specifications. We use state-of-the-art machinery and advanced manufacturing techniques to ensure that every part we produce is of the highest quality. Contact us today to learn more about our extrusion moulding parts service.

Why Choose Extrusion Moulding?

Extrusion moulding is a manufacturing process that allows for the creation of complex shapes with a high degree of accuracy and consistency. It is a cost-effective method for producing large quantities of parts, and the process can be customized to meet a wide range of specifications.

At our company, we specialize in providing customized extrusion moulding parts services. Our team of experts can work with you to create parts that meet your exact needs and specifications. We use the latest machinery and advanced manufacturing techniques to ensure that every part we produce is of the highest quality.

Contact us today to learn more about our extrusion moulding parts service and how we can help you with your manufacturing needs.

Our Extrusion Moulding Manufacturing Capabilities

At our manufacturing facility, we specialize in extrusion molding for a variety of industries. Our state-of-the-art equipment and experienced team allow us to provide high-quality products and excellent customer service.Whether you need extrusion molding for packaging, automotive, or any other industry, we are equipped to meet your needs. Contact us today to learn more about our capabilities and how we can assist with your project.

Custom Design

Our team of experts can create custom designs based on our clients’ requirements using state-of-the-art software.

Prototype Development

We offer prototype development services to help our clients visualize their ideas and make necessary changes before moving to mass production.

Material Selection

We work with a variety of materials, including PVC, TPE, and Polyethylene, to create products that meet our clients’ specifications.

Surface Finishing

We offer a range of surface finishing options, including polishing, texturing, and painting, to enhance the appearance and functionality of our clients’ products.

Extrusion Moulding Parts Manufacturers

Our company specializes in customized squeezing molding parts. Our team can cooperate with you to create parts that meet your precise needs and specifications. We use the most advanced machine and advanced manufacturing technology to ensure that each part we produce is the highest quality

Please contact us to learn more about our squeezing and molding parts services, and how can we help you meet the manufacturing needs

Extrusion Moulding Material And Surface finishing

Plastic: ABS, PVC, PE, PP, PS, PC, PMMA, POM, PA, PET, PPS, TPU, TPE, etc.

Metal: aluminum, copper, brass, stainless steel, titanium, etc.

Painting: This method is suitable for both plastic and metal parts. It involves applying a layer of paint to the surface of the part to protect it from corrosion and wear, as well as to enhance its appearance.

Anodizing: This method is suitable for aluminum, magnesium, titanium, zinc, and lead parts. It involves creating an oxide layer on the surface of the part, which provides it with increased corrosion resistance and improved wear resistance.

Powder coating: This method is suitable for both plastic and metal parts. It involves applying a layer of powder to the surface of the part, which is then cured to create a hard and durable coating.

Plating: This method is suitable for metal parts and involves applying a layer of metal to the surface of the part. This can enhance its appearance, improve its corrosion resistance, or add other functional properties.

Please let us know if you have any specific material requirements or questions about our extrusion moulding parts service. We will be happy to work with you to find the best solution for your needs.

Design review

We work with our clients to ensure that the parts we produce will meet their exact needs and specifications. We use advanced software to create 3D models of every part, allowing us to identify any potential issues before manufacturing begins.

Material selection

We carefully select the raw materials we use to ensure that they are of the highest quality and will produce parts that meet our strict standards.

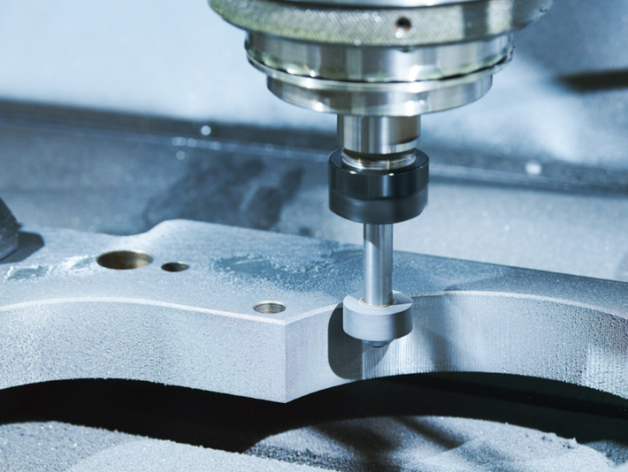

Manufacturing process control

We use state-of-the-art machinery and advanced manufacturing techniques to ensure that every part we produce is of the highest quality. Our team of experts carefully monitors the manufacturing process to ensure that every part meets our strict quality standards.

Inspection and testing

Every part is carefully inspected by our team of experts to ensure that it meets our exact specifications. We use a range of inspection techniques, including visual inspection, dimensional inspection, and material analysis, to ensure that every part is of the highest quality.

Traceability

We maintain detailed records of every part we produce, allowing us to track its progress throughout the manufacturing process and ensure that it meets our strict quality standards.

Continuous improvement

We are committed to continuously improving our quality control process to ensure that we are always providing our clients with the highest quality extrusion moulding parts.

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required extrusion moulding service support by reading FAQ.

Extrusion is a manufacturing process that involves pushing a material through a die to create a specific shape or form. This process can be used with a variety of materials such as plastic, metal, and rubber. During the extrusion process, the raw material is first melted and then pushed through a die, which gives it the desired shape.

A variety of materials can be extruded, including but not limited to plastic, metal, and rubber. The choice of material depends on the product’s specific requirements. Extrusion offers a wide range of possibilities, from soft and flexible materials to rigid and durable ones.If you have a specific material requirement, please let us know and we will do our best to accommodate your needs.

Many extruded products can be recycled, making them a more sustainable option compared to other manufacturing processes. Recycling extruded products can help reduce waste and lower the environmental impact of production. However, not all extruded products are recyclable, so it’s important to check with the supplier or do research on the specific material used.

We offer a variety of surface finishing services, including anodizing, plating, powder coating, and painting. If you have a specific finish requirement, please let us know and we will do our best to accommodate your needs.

Our lead time varies depending on the complexity and quantity of the parts being manufactured. We will provide you with an estimated lead time when you submit your order, and we will keep you informed throughout the manufacturing process.

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.

Extruded products offer a number of benefits over other manufacturing processes. One of the main advantages of extrusion is the ability to create products with consistent quality and accuracy. Extrusion can produce high levels of customization, which is particularly useful when a product needs to meet specific requirements. Extrusion is also a relatively low-cost production method, making it an attractive option for businesses. Another benefit is that extrusion can create complex shapes and designs that would be difficult or impossible to achieve with other manufacturing processes. Finally, extrusion can enhance the performance properties of products, such as making them more durable, heat-resistant or UV-stable.

Latest Blog Posts

Understand our real -time dynamics