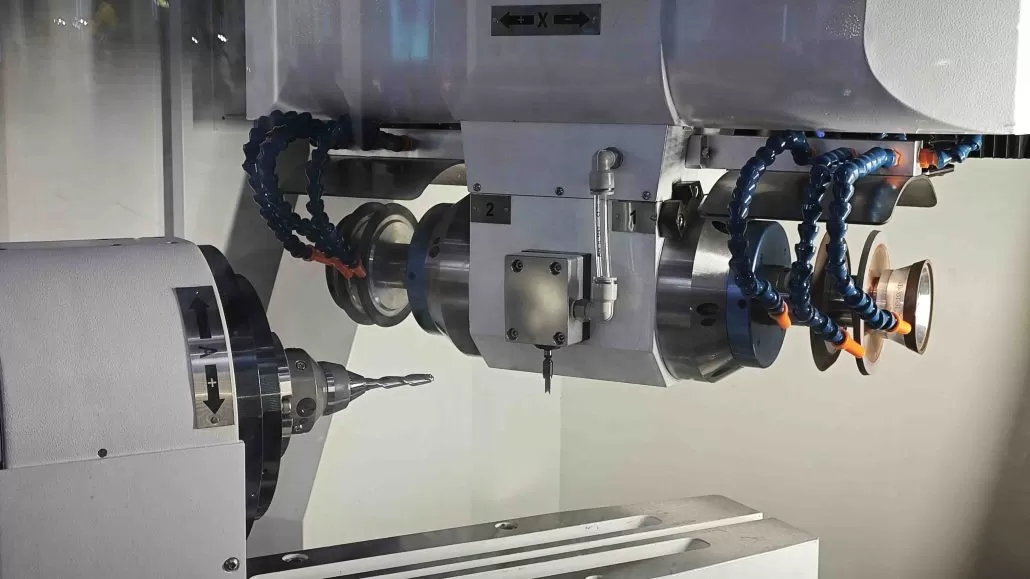

CNC machining, or computer numerical control machining, has transformed the manufacturing industry by streamlining the production process, increasing efficiency, and improving the quality of products. This innovative technology uses computer software to control machines, allowing for accurate and precise production of complex cnc machining parts and products. In this article, we will dive deeper into how CNC machining has revolutionized the manufacturing industry and improved products in various ways.

Precision and Accuracy

One of the most significant advantages of CNC machining is its precision and accuracy. CNC machines can repeat the same task over and over again with the highest level of precision, ensuring that each product is manufactured to exact specifications. This level of precision is not possible with traditional manufacturing methods, which rely heavily on human operators. CNC machines can produce parts with tolerances as tight as a few microns, ensuring that every product is manufactured with the utmost accuracy.

Increased Efficiency

CNC machines are incredibly efficient, enabling manufacturers to produce large quantities of products in a short amount of time. With CNC machines, manufacturers can save time and reduce costs significantly. CNC machines require less labor and can operate 24/7, which means manufacturers can produce more products in less time. This increased efficiency not only saves time but also reduces costs associated with labor and production.

Improved Quality

CNC machines have significantly improved the quality of products produced. They can produce complex shapes and designs that were previously impossible to manufacture. CNC machines can also produce products with a smooth surface finish, reducing the need for additional finishing processes. Additionally, CNC machines can produce intricate designs that are difficult to replicate using traditional manufacturing methods. This has resulted in an improved quality of products and increased customer satisfaction.

Reduced Waste

CNC machines produce less waste than traditional manufacturing methods, as they are programmed to use materials in the most efficient way possible. This has a positive impact on the environment and reduces costs associated with waste disposal. CNC machines can use raw materials more efficiently, minimizing waste and maximizing production. By reducing waste, CNC machining has made the manufacturing process more sustainable and environmentally friendly.

Conclusion

CNC machining has revolutionized the manufacturing industry and improved products in various ways. From increased precision and accuracy to improved quality and reduced waste, CNC machining has changed the way manufacturers produce products. As technology continues to advance, it is safe to say that CNC machining will continue to play a crucial role in the manufacturing industry. As a result, the manufacturing industry can continue to produce high-quality products more efficiently and sustainably than ever before.