CNC machining from the traditional production mode to flexible production mode, through computer control, reduce manpower input, improve work efficiency and accuracy. Compared with traditional mechanical machining, CNC machining has more advantages in production efficiency, especially the machine tool internal structure of complex parts machining, CNC machining can achieve more precise processing, improve the quality and durability of parts, using CNC machining technology can quickly realize parts machining, so that enterprises in a short time to achieve rapid adjustment of production, Meet the actual demand of the market.

In the current market environment, consumer demand for products is increasingly diversified, on-demand manufacturing can meet this demand, to achieve more intelligent production, here, we will explain how CNC machining is to achieve on-demand manufacturing, and its machining methods, what are the advantages of common applications, we provide information will help you make full use of CNC machining technology.

What manufacturing on demand?

On-demand manufacturing refers to the manufacturing mode that adopts personalized production mode to produce according to customer’s demand, customization degree and time requirement after forming an order. Compared with traditional mass production, on-demand manufacturing has realized the transformation from mass production to personalized production, has the advantages of flexibility and high efficiency, and helps to improve the efficiency of the supply chain and reduce the inventory level.

Through information technology and other means, on-demand manufacturing improves the project management, planning, supply chain and other links in the production process, so that production can respond to customer needs more quickly and accurately. In this production mode, manufacturers can better grasp the market information, adjust the production plan according to the market demand, improve the market competitiveness of products.

How does CNC machining work?

CNC machining can process a variety of materials, including metal, plastic, wood and so on. First, the design drawings need to be converted into a format that the machine can understand, and CAD software is generally used to accomplish this process. These CAD files are then imported into CAM software, which analyzes the required machining path and cutting tool, and generates a tool roadmap. The tool roadmap includes information such as machining sequence, working speed and cutting feed.

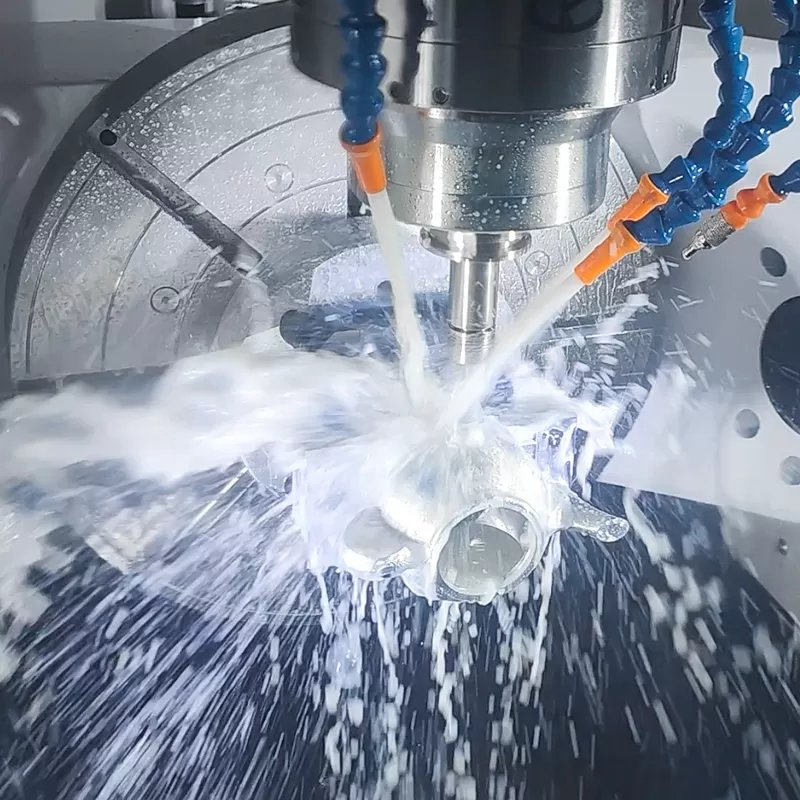

Once the tool roadmap is generated, it can be transferred to the CNC controller. A CNC controller is a computer designed to interpret code and drive the machine. In the controller, the operator can make final adjustments and Settings. Once ready, the controller sends instructions to the machine and begins machining.

Because CNC machining is controlled by computer, it can be processed with high precision, up to 0.001 inch precision. In addition, CNC machining allows high volume and repeatable machining, thus improving production efficiency. Therefore, it is widely used in the manufacturing industry, including automobile manufacturing, machinery manufacturing, electronic manufacturing and so on.

CNC machining on-demand manufacturing | type of CNC machine tools

CNC machine can reduce manual error rate, improve machining accuracy, more can speed up production, shorten production cycle, reduce production costs, has been more and more widely used. Different types of CNC machine tools are suitable for different production needs. The following are several common types of CNC machine tools.

CNC lathe

CNC lathe is a kind of equipment that can automatically complete the feeding, turning and other machining processes of the turning tool. CNC lathes use digital coding control system, according to the pre-set program, machining. Thanks to the programmable controller, the operation is simple and more operations can be completed, achieving high efficiency and productivity. By processing high precision and high quality products, greatly improve the production efficiency.

CNC lathes have the characteristics of high efficiency, high precision, high automation, high flexibility and so on. Therefore, it is widely used in the manufacturing of various shaft turning parts, such as copper, aluminum, steel, stainless steel and other materials machining. It is mainly used in the manufacture of bearings, springs, screws, nuts, gears and other transmission parts.

CNC milling machine

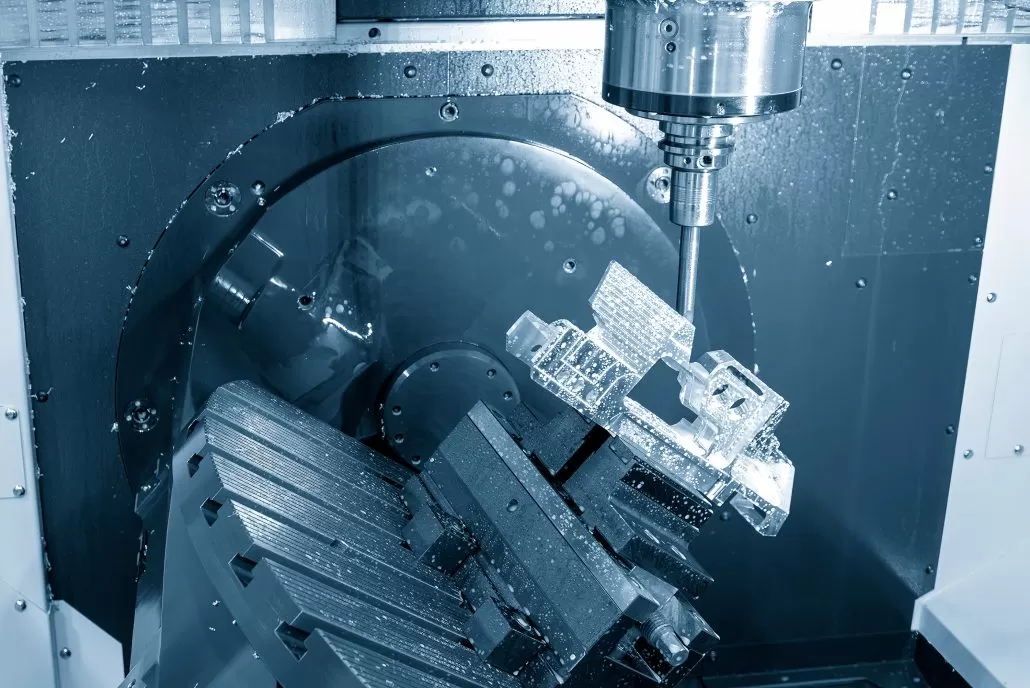

CNC milling machine is a kind of equipment that can automatically complete the feed, milling and other machining processes of milling cutter. Compared with other machine tools, CNC milling machines are capable of machining complex shapes rather than simply straight lines. The use of CNC milling machine, in mass production at the same time, can ensure the high quality of products. This operation, can save a lot of time and work cost, and make machining accuracy greatly improved.

In the modern manufacturing industry, CNC milling machine has a wide range of applications, including aviation, automotive, electronics and other industries. It can process three – dimensional surface, plane and linear curve and other shapes of parts. CNC milling machine not only provides an efficient machining method, but also can quickly replace the machined parts, reducing the cost of equipment.

According to different machining needs and parts shape, you can choose different CNC machine tools for machining. In addition to CNC lathes and CNC milling machines, there are other types of CNC machine tools, such as CNC drilling machines, CNC grinding machines and so on. Enterprises should choose different types of CNC machine tools according to the production needs and machining objects.

CNC machining on demand manufacturing advantages

CNC machining on demand manufacturing is an affordable way to produce high quality products and components in a short time. Its flexibility and fast production will greatly improve the productivity and efficiency of manufacturers and suppliers, and provide accurate solutions to market needs. This manufacturing mode is more suitable than the traditional manufacturing mode in some cases, and its advantages are mainly reflected in the following aspects:

tailored

CNC machining on demand manufacturing allows products to be customized. The drawings or samples provided by the customer can be accurately copied, so the customer can get the specific product he needs, rather than choosing the closest one from a large number of standardized products. This way can meet the personalized needs of customers and improve customer satisfaction

Increase production

On-demand manufacturing enables manufacturers to produce products and components in the required quantities in response to market demand, thereby increasing productivity. In the need to produce a large number of parts, CNC machining software only in accordance with the program instructions to operate, and it can run 24 hours uninterrupted, greatly improving the production efficiency and output.

Reduce cost

Manufacturing on demand using CNC can greatly reduce the cost of production because manufacturers only need to make the required number of parts. Because CNC machining uses computer software to control the machining process, it can avoid suppliers wasting resources and time to manufacture too many products or parts, thus reducing production costs.

Reduce waste

CNC machining on demand manufacturing can reduce waste. Because CNC machines can operate according to preset procedures, thus minimizing waste materials and damage.

Flexible manufacturing methods

On-demand manufacturing means that companies can make components and finished products as needed, rather than just producing large quantities of the same products as traditional manufacturing methods. CNC machining technology can easily cut and process products of different materials, shapes and sizes, able to adapt to different customer needs and market changes.

Higher product quality

Higher precision and efficiency in manufacturing parts and prototypes. Because the machining process is balanced by a multi-axis control system, it is not a problem to achieve high precision manufacturing. This type of machining provides NC machine tool operators and designers with more design and production freedom. This means that you can make parts of any shape and size, from precision molds to structural parts to large products. CNC machining can even handle complex machining tasks, such as molding, laser cutting, stamping, rotation, grinding, and so on.

CNC machining selects materials on demand

CNC machining is divided into three categories, which are giant machining, surface machining and axial machining. Different machining types have different requirements for materials. The following will introduce the CNC machining technology applicable to different materials to help you choose more targeted machining materials.

materials for Large machining

Jumbo machining is a kind of advanced CNC machining technology for large parts. In the giant machining, the need to use high strength, high hardness, high temperature stability of materials.

| Material | Characteristic | Application |

|---|---|---|

| Titanium alloy | High strength, low density, good corrosion resistance, high temperature resistance | Manufacturing in aviation, aerospace, biochemistry and other fields |

| Aluminum magnesium alloy | High strength and low density | Ships, automobiles, machinery |

| Stainless steel | Strong toughness, good corrosion resistance | Chemical industry and ocean |

| tungsten-aluminum | High wear resistance and thermal conductivity | Make parts that rotate at high speeds, such as bearings and blades for aircraft engines |

| plastic | Low cost, light weight, convenient machining, good flexibility | Manufacturing a variety of low density components and equipment manufacturing |

| copper | Good corrosion resistance | Electronic circuit, generator, transformer, cable and other manufacturing |

| polyurethane | Excellent elasticity and wear resistance | Cars, airlines, ships |

Materials for surface machining

Surface machining is used to improve the surface quality and performance of machined parts to meet specific engineering requirements. Surface machining usually involves compression, cutting, grinding, grinding, spraying and other processes.

| Material | Characteristic | Application |

|---|---|---|

| ceramic | Wear resistance | Used for difficult projects |

| Tungsten-molybdenum alloy | High temperature resistance, wear resistance, corrosion resistance | Used to improve the surface durability of tools |

| Chrome alloy | Corrosion resistance | Used in manufacturing industrial components and aerospace facilities |

| 7075 aluminium alloy | Good electrical and thermal conductivity, high strength and high plasticity | Aerospace, automotive, electronics, robotics, packaging and construction |

| brass | Electrical and thermal conductivity | Electronics and plumbing |

materials for Axially machining

Axial machining is a kind of machining technology in which the machining cutting is carried out along the axial direction of the workpiece. This machining method is usually used in the production of long parts, such as spindle parts, long rods, and so on.

| Material | Characteristic | Application |

|---|---|---|

| Carbon steel | High stiffness, low cost, easy to cut | Bearings and pins are produced |

| High speed steel | Excellent hardness, machinability and wear resistance | Used in the field of high precision machining |

| Hard alloy | High strength, good cutting performance, excellent wear performance | Used to produce high strength and hardness cutting tools |

| plastic | Lightweight and anticorrosive | Electronic product casing |

| graphite | Electrical and thermal conductivity | Used for machining electronic components, coils and fuses |

Common applications of CNC machining on demand manufacturing

CNC machining on demand manufacturing technology can be applied to a variety of fields, such as automotive parts manufacturing, medical devices, aerospace, mold manufacturing, etc.

The following are common applications of CNC machining in these fields:

Automobile parts manufacturing

In automobile production, CNC machining technology can be used to produce engine parts, brake parts, pump parts and so on. CNC machining technology can produce these parts with high precision, and can automatically monitor production quality and adjust during production.

aerospace parts manufacturing

The aerospace industry is a prime example of CNC machining technology. CNC machining technology can be used to produce various aerospace parts, such as engine parts, hydraulic system parts, hub parts, missile parts, ship parts, etc. These parts require high precision, high strength and corrosion resistance.

Medical instrument

The use of CNC machining on demand manufacturing allows for the manufacture of more accurate devices for the medical industry. For example, dentists use CNC machining technology to make dental models and other parts related to oral health. CNC machining technology is also increasingly used in the manufacture of medical instruments such as cardiac pacemakers, whole-body instruments and artificial joints.

Metal parts manufacturing

Finally, CNC machining on demand manufacturing can also produce metal parts, such as sheet metal, aluminum alloy parts, magnesium alloy parts, magnetic alloy parts, stainless steel parts, titanium alloy parts and plasma cutting parts. These metal parts are widely used in construction, automobiles, motorcycles, aircraft and electronic equipment.

Electronic equipment industry

Modern electronic equipment requires precision machining to produce a wide range of electronic components, such as chips and printed circuit boards. CNC machining can precisely carve the shape and structure of these components, while ensuring that they meet various standards, such as durability, size and so on.

Whether it’s manufacturing high-precision parts for the automotive industry, highly personalized equipment for the medical industry, a wide variety of components and equipment for the electronics industry, or complex parts and components for the aerospace industry, CNC machining technology can quickly and accurately complete a variety of complex tasks

Why CNC machining on demand manufacturing rather than other technologies?

In modern manufacturing, there are many different machining technologies to choose from, and it can be quite challenging to decide between CNC machining centers and other technologies. There are many factors to consider to ensure you make the best choice. Here’s how this technique compares to other methods:

CNC machining on demand manufacturing VS 3D printing

CNC machining on demand manufacturing is a very flexible technology. It can be used to make almost all types of parts, from small to large, from simple to complex. When custom parts are needed, CNC machining on demand manufacturing can quickly cut or machined to the desired shape, which greatly improves manufacturing efficiency. In contrast, 3D printing has to build parts layer by layer, which can take longer, while injection molding requires higher-cost molds to be manufactured.

In terms of cost, 3D printing requires expensive equipment and consumables to be realized, while the equipment processed by CNC is basically a one-time investment and has a long service life.

CNC machining on demand manufacturing VS stamping

CNC machining on demand manufacturing is geared to small batch production and personalized needs without any molds, templates or traditional profile machining. In this mode of production, design graphics are programmed into computer-controlled machines, allowing the machine to create products by cutting and sculpting on a variety of materials.

For mass manufacturing, small batch production or need to customize personalized needs, CNC machining on demand manufacturing is more advantageous. This method can save time and money, because there is no need to spend a lot of time and expense to make molds and templates.

When you need to make customized, highly accurate products, CNC manufacturing on demand is often better suited than stamping.

Longsheng technology is used for CNC machining

Are you looking for a reliable and efficient CNC machining service provider? Longsheng Technology is your best choice. We provide our customers with one-stop CNC machining on demand manufacturing services, designed to meet your various needs. We have rich experience and professional team, can efficiently complete a variety of machining tasks.

We provide CNC milling, laser cutting, stamping, drilling, turning and other services. Our equipment and software are the most advanced and can meet a variety of different machining needs. Our machining process is strict, manufacturing products of high precision, and drawings and requirements fully match.

Longsheng Technology can also provide raw material procurement, machining, surface treatment and other comprehensive services, so as to save time and cost for customers. We have a multi-lingual, highly skilled team of professionals who can provide a full range of services and support to our customers. At the same time, our customer service team is also very equipment and attention to detail, to ensure that customers are not affected during the implementation of the project.

We provide the highest quality online CNC machining service, so that you can be assured to deliver to our key production steps. If you would like to know more about our services and how to start custom machining, please feel free to contact us!