As an important metal element, titanium is widely used in aerospace, chemical industry, medical and other fields. Its price fluctuations are not only affected by market supply and demand, but also related to the global economic situation, policy adjustments, production costs and international situations. The trade situation is closely related. This article explores the fluctuations of trade prices from multiple angles.

What is titanium?

Titanium (Ti), a chemical element, is a silver-gray metal in Group 4 (IVb) of the periodic table of elements. Titanium is a lightweight, high-strength, low-corrosion-resistant structural metal used in alloy form for components in high-speed aircraft. In fact, titanium is the ninth most abundant element on Earth. It is commonly mined from various minerals found in the earth’s crust, such as ilmenite, sphene, and rutile.

What are the main properties of titanium?

- Biocompatibility: Titanium metal is regarded as a leader in biocompatibility due to its inertness, good resistance to body fluid corrosion, characteristics of bonding with bones (such as bone integration) and high cyclic fatigue limits.As a result, titanium has become suitable for use in the manufacture of bone, joint surgery and dental implants.

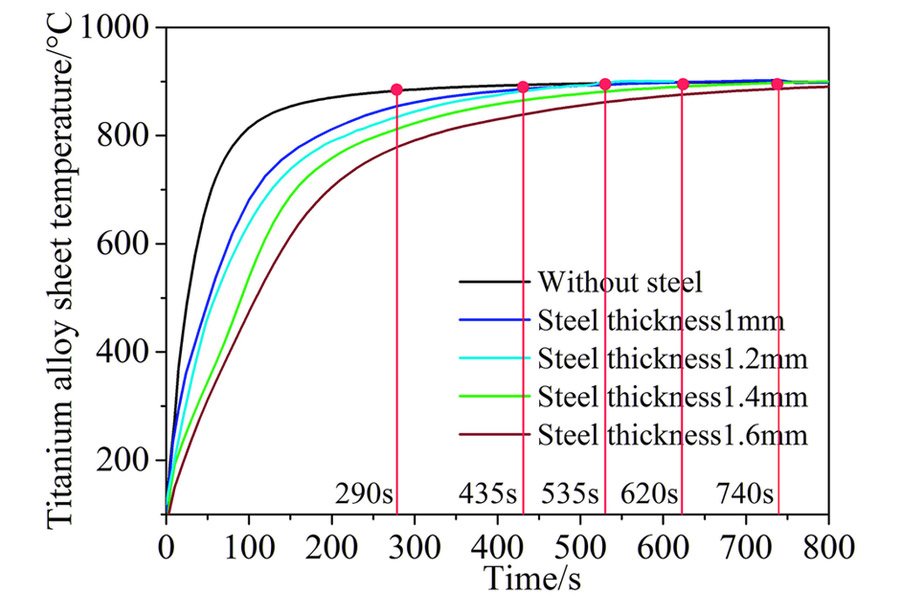

- Heat Resistance: Titanium has low thermal conductivity. Therefore, titanium has become the material of choice for use in high-temperature environments such as machinery manufacturing, spacecraft, jet engines, missiles and automobiles.

- Non-magnetic: Titanium does not have magnetic properties, but it may transform into paramagnetic properties under the influence of a magnetic field.

- Ductility: As a metal material, titanium’s ductility will gradually increase as the temperature rises. In addition, by processing titanium with aluminum and other stretchable metals into alloys, the plasticity of the material can be effectively improved.

- Low thermal expansion: Titanium has a relatively low thermal expansion coefficient. Under extreme temperature conditions, titanium does not exhibit the expansion or contraction effects that other materials, such as steel, can achieve. Because titanium has low thermal expansion properties, it is considered a building material used at high temperatures, such as in aviation, aerospace, aerospace, and large-scale construction and high-rise buildings at fire scenes.

- Excellent fatigue resistance: Titanium exhibits excellent fatigue resistance properties. Titanium has therefore become the material of choice for the aerospace industry, where critical aircraft structures such as landing gear, hydraulic systems and exhaust pipes are subject to cyclic loads.

- Anti-corrosion properties: Titanium is particularly important in the field of marine and chemical processing because of its excellent resistance to seawater, chlorine and other corrosive agents.

- Lightweight: Compared to many other metals, titanium has a relatively low density. The use of titanium metal in aviation, automotive and other industrial fields can make products lightweight, thereby reducing material costs and energy consumption, while improving their reliability and extending their service life. Titanium is ideal for manufacturing lightweight structures and components in the aerospace and automotive industries.

- High Strength: The strength of titanium is comparable to the strength of steel. In addition, due to its high elastic modulus, it will return to its original shape after deformation under impact load, so it has good impact resistance. However, due to titanium’s relatively low density, a titanium structure with the same strength weighs approximately 45% less than its steel counterpart. Due to its excellent strength-to-weight ratio, titanium is widely used in aerospace, automotive manufacturing, medical fields, and shipbuilding.

How Does Titanium Pricing Fluctuate?

- Supply and demand: The price of titanium is affected by market supply and demand. Titanium prices typically rise when supply is tight or demand increases; conversely, oversupply or falling demand can cause prices to fall.

- Macroeconomic conditions: Global economic conditions have an important impact on titanium prices. Economic growth and stability typically lead to increased demand for titanium, supporting prices, while economic recession or instability can lead to lower demand, putting pressure on prices.

- Production cost: The production cost of titanium is affected by various factors such as raw material prices, energy prices, labor costs, etc. If these factors increase significantly, it may push up the production cost of titanium, which will have an impact on the price of titanium.

- Geopolitical factors: Geopolitical tensions, trade wars, international sanctions and other factors may have an impact on the price of titanium, especially titanium exporting and importing countries.

- Exchange rate fluctuations: Titanium is an international commodity, so exchange rate fluctuations will also have an impact on the price of titanium, especially the international trade of titanium.

- Technological progress: The aviation industry uses titanium materials extensively to manufacture fuselages, landing gear and engines. As the aviation industry continues to innovate, coupled with rising fuel costs, aircraft manufacturers are taking advantage of titanium’s weight-to-strength ratio capabilities. It makes the aircraft lighter, thus providing an effective method of saving fuel. Therefore, continued demand for titanium will change the price balance as producers will struggle to meet demand.

- Alternative materials: HSCR steel is a low-cost alternative to titanium. It is favored for its specific strength, high fatigue strength, good toughness and corrosion resistance. Some aircraft manufacturers are considering its efficiency in actual flight. Overall, HSCR availability, quality, and price factors influence titanium’s position in the market.

What is the impact of raw material prices on the overall cost of titanium?

Raw material prices, especially titanium ore and scrap, have a significant impact on the overall cost of titanium.

★The impact of titanium ore prices

| Impact | Describe |

| Increase in direct costs | Titanium ore is the main raw material for the production of titanium materials, and its price fluctuations directly affect the production cost of titanium materials. When the price of titanium ore rises, the production cost of titanium materials will increase accordingly, which may push up the market price of titanium materials. On the contrary, falling titanium ore prices will reduce production costs. |

| Tight supply and price fluctuations | The uneven distribution of titanium ore resources and the difficulty of mining may lead to fluctuations on the supply side. When market supply is tight, titanium ore prices tend to rise, further increasing the production cost of titanium materials. For example, in the first quarter of 2024, China’s titanium ore market prices showed an upward trend, and the prices of small and medium-sized titanium ores continued to rise, which directly led to an increase in titanium material production costs. |

| corporate profitability | Fluctuations in titanium ore prices will also affect the profitability of titanium material production companies. When titanium ore prices are high, companies’ production costs increase and profit margins are compressed. In order to maintain profitability, companies may need to respond by increasing product prices, optimizing production processes, or seeking alternative raw materials. |

★The impact of scrap prices

| Impact | Describe |

| Recycling value | Waste materials also have certain recycling value in the titanium production process. Through professional handling and processing, waste materials can be converted into reusable raw materials, thereby reducing production costs. Therefore, fluctuations in scrap prices will also affect the overall cost of titanium materials. |

| Market supply and demand | The supply and demand relationship in the scrap market will also affect its price. When scrap supply is plentiful, prices can be relatively low; when demand increases or supply decreases, prices can rise. This price fluctuation will also be reflected in the production cost of titanium materials. |

| Environmental protection and sustainable development | The recycling of waste materials not only helps reduce production costs, but also helps achieve environmental protection and sustainable development goals. As the world pays increasing attention to environmental protection issues, the recycling value of waste materials will also be further enhanced. |

How do common production methods affect the price of titanium?

√Kroll process

The Kroll process is a traditional titanium preparation method that includes many steps requiring high temperatures, which results in high energy consumption and production costs. In addition, this process also requires the use of large amounts of reducing agents (such as magnesium) and chlorinating agents, and the cost of these raw materials is also relatively high. Therefore, the price of titanium materials produced by the Kroll process is usually higher.

√Smelting

Smelting is an important link in the titanium production process. Different melting methods (such as vacuum consumable arc furnace melting, electron beam melting, etc.) have different impacts on production costs. For example, vacuum consumable electric arc furnace smelting can effectively remove impurities and gases in titanium materials and improve product quality, but its equipment investment and maintenance costs are also relatively high. Therefore, the price of titanium materials using different smelting methods will also vary.

√Forging

Forging is an important link in the titanium processing process. The forging process requires a large amount of energy and mold materials, and has high requirements on equipment and processes. Therefore, forging costs account for a certain proportion of the overall cost of titanium materials. The selection and optimization of forging processes are of great significance for reducing production costs and improving product quality.

Titanium’s new trend in 3D printing

The application of 3D printing technology has revolutionized titanium metal, completely changing manufacturing technology and broadening its application range. Additive manufacturing (AM) can create complex geometries not possible with traditional machining methods. Especially in the aerospace and biomedical industries where individualized lightweight, high-strength components are required.

Key technical parameters

- Layer thickness: Typically between 30-60 microns so that precise dimensions and surface finish can be controlled.

- Build volume: Industrial-grade 3D printers for titanium typically have build volumes of up to 300 x 300 x 400 mm, enabling the production of large parts.

- Material yield: titanium powder utilization rate can reach 95%, thus reducing waste and costs, making it cost-effective.

- Mechanical properties: The tensile strength range is 900-950 MPa, and the elongation at break is about 10-15%, so it still has the good mechanical properties inherent to the metal.

- Density: Achieves near full density, even up to 99.7%, ensuring structural integrity and consistent performance.

Benefits of using titanium in 3D printing

- Customizability: Implants can be made for specific patients; aerospace components can also be designed to meet specific requirements.

- Reduced lead times: Months can be shortened from prototyping to production, especially if techniques other than AM are used, such as subtractive manufacturing, which minimizes waste as only the parts that are needed are removed.

- Material efficiency: Complex shapes such as lattice structures or channels can be easily created internally, which is important for lightweight performance and functionality.

Comparison of wholesale and retail prices of titanium materials in China

Titanium is a valuable metal with numerous applications in different industries including aerospace, defense and medical. The price of titanium in China varies depending on the source and use. Typically, wholesale prices for titanium are lower than retail prices.

In China, the wholesale price of titanium is 60-70 yuan per kilogram, while the retail price is about 90-100 yuan per kilogram. Prices may vary depending on grade, quality and quantity purchased. For example, grade 1 and 2 titanium are less expensive than grade 5 titanium because they have better performance and durability.

The price of titanium is also affected by the price of raw materials. In recent years, the price of raw materials such as ilmenite and rutile has increased, pushing up the price of titanium. Titanium supply and demand will also affect prices. When the demand for titanium is high, the price may rise; conversely, when the demand is low, the price may fall.

In the Chinese market, manufacturers purchase titanium at wholesale prices and then process it into various products for sale at retail prices. Titanium products such as bicycle frames, jewelry and dental implants have retail prices higher than wholesale prices. This is because the value added from processing, marketing and distribution of titanium products is included in the retail price.

All in all, the wholesale price of titanium is lower than the retail price, and multiple factors such as raw materials, supply and demand, and the grade of titanium determine the cost. Regardless of the price, however, titanium remains a valuable metal because of its properties and numerous applications in various industries.

What are the common applications of titanium?

Aerospace

Titanium is an excellent choice for manufacturing aerospace components and vehicles, accounting for nearly 50% of the total weight of aircraft. It is often used to make critical components such as landing gear, firewalls and hydraulic systems. Titanium is valued in the aerospace industry for its low density, high strength-to-weight ratio, and resistance to corrosion and fatigue.

Marine equipment

Titanium is highly resistant to corrosion by seawater, making it an ideal choice for ship drilling rigs, propeller blades and shafts, and other parts that are submerged in water.

Sports application

Titanium’s high strength-to-weight ratio lends itself to a wide range of applications in the sports industry. The material is used as components in sporting goods such as tennis rackets, baseball bats, golf clubs, bicycle frames and ski equipment.

Medical industry

Due to its inertness and non-toxicity, titanium is widely used in the medical field, including surgical implants, dental implants, surgical tools and ancillary equipment.

fireworks

Titanium powder produces bright white sparks that are used in fireworks.

jewelry

Titanium is commonly used in jewelry including piercings, watches, necklaces, rings, and other items because of its durability, lightness, and corrosion resistance. Additionally, titanium is sometimes mixed with gold to create a 24-karat gold alloy, which is stronger and more durable than its pure gold alternative.

Automobile industry

Titanium is commonly used in the automotive industry to make engine components, crankshafts, valve seats, connecting rods, exhaust systems, suspension systems and car frames. Titanium is favored in the automotive industry for its low density, high strength-to-weight ratio, and resistance to corrosion and heat. Not only can these properties of titanium improve aerodynamics and performance, but its low density and high strength can also make the manufacturing process more cost-effective because less material can be used for a given application.

Titanium recycling process and its advantages?

Titanium recycling process

The titanium recycling process requires some complex operations before the material can be used again without losing its properties.

- Classification: Classify scrap titanium alloys according to composition, use, etc. for subsequent processing.

- Smelting:①Fire method: Put the scrap titanium alloy into a high-temperature furnace, over-oxidize it at high temperature to form titanate, and separate useful metal elements. ②Electric arc furnace method: Using the principle of electrochemistry, the scrap titanium alloy is melted and then purified using high-voltage current.

- Refining: Refining in a vacuum atmosphere or inert gas to remove impurities and ensure the purity of the metal.

Advantages of titanium recycling

From an economic perspective, this procedure reduces the extraction of expensive raw materials that damage nature. If we use recycled materials instead of making virgin metals from ores, the energy consumption will be much less. At the same time, it also helps reduce waste, since even small amounts count in sustainable manufacturing methods. Additionally, used products perform just as good as new, making them a reliable and effective alternative for aerospace, medical industries, chemical industries, and more. Achieving these procedures and benefits demonstrates how important improvements in recycling-related technologies are for responsible management of resources and environmental protection.

What are some ways for companies to mitigate the impact of titanium prices?

※Supplier Diversification: Relying on a single titanium supplier can be risky. By diversifying supplies, companies can reduce the risk of supply disruptions and price fluctuations. Maintaining relationships with multiple suppliers ensures supply chain stability.

※Long-term contracts: Signing long-term contracts with suppliers ensures price stability. These contracts often include fixed or predetermined pricing arrangements that protect the business from sudden price increases.

※Inventory Management: Effective inventory management is crucial. By carefully monitoring inventory levels and demand forecasts, companies can ensure adequate supplies of titanium without overstocking and incurring warehousing costs.

※Recycling Program: Implementing a titanium recycling program can reduce reliance on new, more expensive titanium resources. Recycling not only supports sustainability goals but also provides cost savings at a time when prices are high.

※Hedging strategies: Some companies use financial instruments such as futures contracts to hedge titanium price fluctuations. This allows them to lock in a price for future purchases, thereby reducing uncertainty.

※Continuous Monitoring: Stay informed about market trends and geopolitical developments. Regularly assess the health of your titanium supply chain and adjust your strategy accordingly.

※Partnerships: Build strong relationships with suppliers, industry associations and experts. Collaborative efforts can provide early warning of potential disruptions and collaborative problem solving.

※Cost reduction measures: Look for opportunities to reduce titanium consumption during manufacturing. Improved efficiencies and material substitution can help mitigate cost increases.

Forecast of future trends in titanium prices

Rising amid fluctuations: Under the combined influence of various factors such as supply and demand, production costs, and the global economic environment, titanium prices may show a rising trend amid fluctuations in the future. But it’s important to note that this increase is likely to be gradual and moderate, rather than sharp.

Seasonal fluctuations: Titanium prices may also be affected by seasonal factors. For example, during the peak seasons of certain downstream industries, demand for titanium materials may increase, thereby pushing up titanium prices; while during off-seasons, weakening demand may cause titanium prices to fall.

Uncertain factors: Due to the existence of uncertain factors such as the global economic environment and geopolitical situation, the future trend of titanium prices may also be affected by these factors and fluctuate.

Causes To Select LongSheng

When selecting LongSheng, the next components could must be thought of:

- Product High quality: The standard of LongSheng’s merchandise could be an vital purpose for selecting it. If its product high quality is widely known, this may very well be a compelling purpose.

- Service High quality: The standard of LongSheng’s companies is also an vital consideration. If it offers high-quality buyer companies, together with pre-sales session and after-sales help, this may very well be an vital purpose for selecting it.

- Value: If LongSheng’s product costs are cheap and cost-effective, this may very well be an vital purpose for selecting it.

- Model Fame: If LongSheng has model popularity, this may very well be an vital purpose for selecting it. Model popularity may embody buyer opinions, business evaluations, and extra.

conclusion

Titanium price fluctuations are affected by a variety of factors. In the future, with the continuous development of the global economy and the adjustment of industrial structure, the demand for titanium will continue to grow. At the same time, with the advancement of technology and the strengthening of environmental protection policies, the cost of mining and refining titanium may also change. Therefore, the fluctuations in titanium prices will be more complex and changeable.

For relevant companies and investors, they need to pay close attention to market dynamics and policy changes, and adjust business strategies and investment decisions in a timely manner. At the same time, it is also necessary to strengthen investment in technology research and development and environmental protection to improve the added value and market competitiveness of titanium products to cope with possible future price fluctuations and market challenges.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

Can titanium be recycled? Will this affect its price?

Yes, recycling titanium is an important part of its market behavior. Scrap titanium fragments can be collected and reprocessed, mainly for industrial use. The availability of second-hand titanium may affect the price of titanium because it is a cheaper option compared to new alloys made from this metal. Companies looking for commercial or industrial scrap metal recycling can start by contacting local scrap yards that specialize in metals like titanium.

Why does the price of titanium change so frequently?

There are many reasons why titanium prices often rise and fall. These include fluctuations in raw material costs, which may be affected by magnesium prices or other elements used along with carbides in production processes involving this metal. It may also be that different industries sometimes see reduced demand for titanium, especially in the aerospace industry, which places a high value on its extreme environmental resistance; finally, global economic conditions may also affect its supply around the world, while Not just locally, as some types of apps are more specialized than others, so differences can arise even within the same category.

Is titanium more expensive than gold?

Titanium is no more expensive than gold. In fact, from a regular market price point of view, the price of gold is usually much higher than that of titanium. Gold, as a precious metal, has been favored since ancient times for its rarity, stability and beauty. Compared with titanium, although titanium is also an important metal element with a wide range of applications, its price is usually much lower than gold. The price of titanium is mainly affected by various factors such as global supply and demand, production costs, economic environment and policy factors. Although titanium is in high demand in some specific areas, its price is not as high as gold because of its relatively low mining and processing costs and relatively abundant supply.

How much does titanium alloy cost per kilogram?

Titanium alloy is a metal material with excellent properties and is widely used in aviation, aerospace, medical, chemical and other fields. However, many consumers still have many doubts about the price of titanium alloys. At present, the price of titanium alloys on the Chinese market is approximately between 300 and 500 yuan/kg. The specific price will also be affected by factors such as raw material prices, production processes, and quality requirements.