CNC machining has revolutionized the manufacturing industry by providing precise and efficient manufacturing processes. It has become one of the most popular methods for creating custom parts and components that are used in a wide range of industries, including automotive, aerospace, medical, and industrial applications. However, one of the most common questions asked by clients is, “how long does CNC machining take?” In this article, we will provide a detailed guide on CNC machining and the factors that determine the time taken for the process.

Understanding CNC Machining

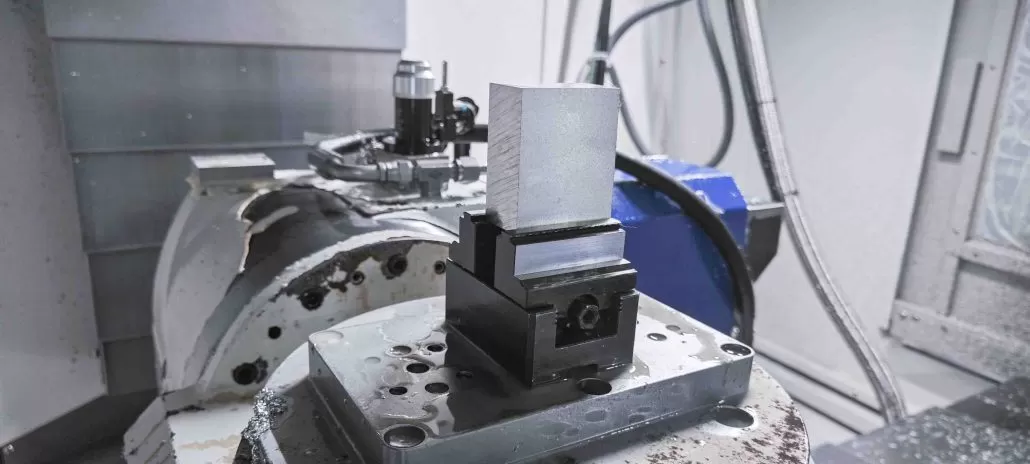

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control machinery tools. The process involves feeding a design or model into the software program, which then directs the machine tools to create the desired object from a raw material such as metal, plastic, or wood.

CNC parts machining is a versatile process that can create complex shapes, intricate designs, and precise components with ease. It is commonly used in the production of components that require tight tolerances and high accuracy, such as gears, bearings, and housings.

Factors Affecting CNC Machining Time

Several factors determine how long CNC machining will take. These include:

1. Complexity of the Design

The complexity of the design is a significant factor that affects the time taken for CNC machining. Intricate designs with multiple surfaces, holes, and angles require more time to machine than simple designs. This is because complex designs require more tool movements, and each movement takes time to complete.

2. Material Used

Different materials have varying levels of hardness, which affects the time taken to machine them. Harder materials such as titanium and stainless steel take longer to machine than softer materials like aluminum and plastic. This is because harder materials are more difficult to cut and require more force, which slows down the machining process.

3. Machine Speed

The speed at which the machine tools operate affects the time taken for CNC machining services. Faster machines can complete the process much quicker than slower machines. The machine speed is determined by the cutting tools, the spindle speed, and the feed rate. Higher spindle speeds and feed rates result in faster machining times.

4. Number of Parts

The number of parts required determines the time taken for CNC machining. Larger quantities take longer to produce than smaller ones. This is because each part requires the same amount of time to machine, and producing more parts means more time is needed to complete the job.

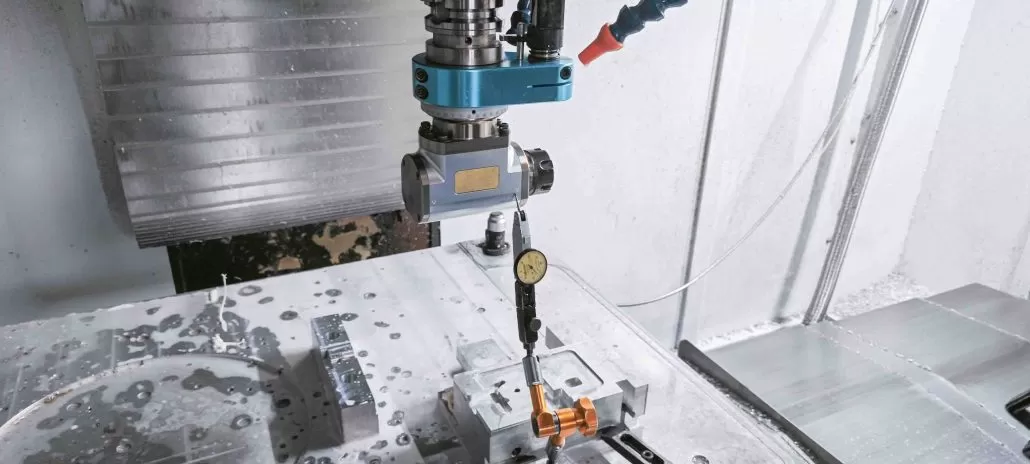

5. Tool Changes

The process of changing tools during CNC machining also affects the time taken. The more tool changes required, the longer the process will take. Tool changes are necessary when different cutting tools are required to create different features on the part. Each tool change takes time to complete, which adds to the overall machining time.

Conclusion

In conclusion, the time taken for CNC machining depends on several factors, including the complexity of the design, material used, machine speed, number of parts, and tool changes. Understanding these factors is crucial when estimating the time and cost of CNC machining. To ensure a successful CNC machining project, it is essential to work with a reliable and experienced CNC machining service provider. If you are looking for a reliable and efficient CNC machining service, contact {longsheng} today. Our team of experts can help you with all your CNC machining needs.