In mechanical engineering, springs play a crucial role in storing and releasing energy. This article explores how mechanical springs function, their types, characteristics, and common applications. It also highlights how precision CNC machining parts are crucial in manufacturing high-quality springs.

What is a Mechanical Spring?

Mechanical springs are elastic devices that store mechanical potential energy when deformed through compression, tension, or torsion.

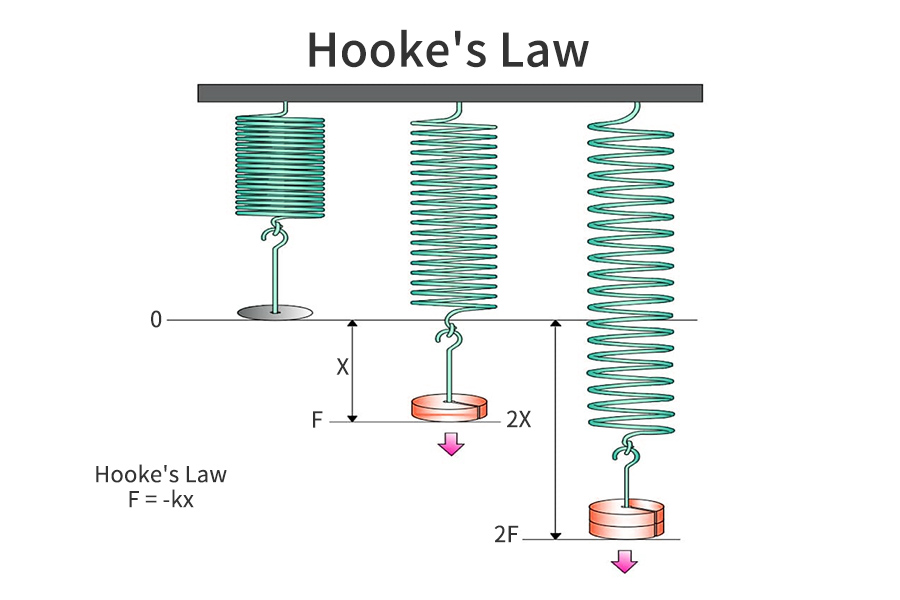

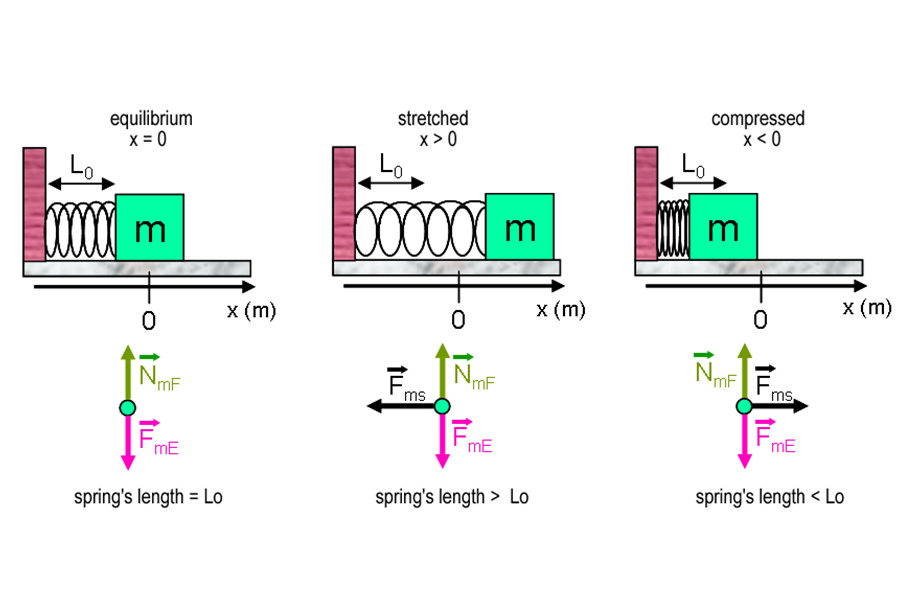

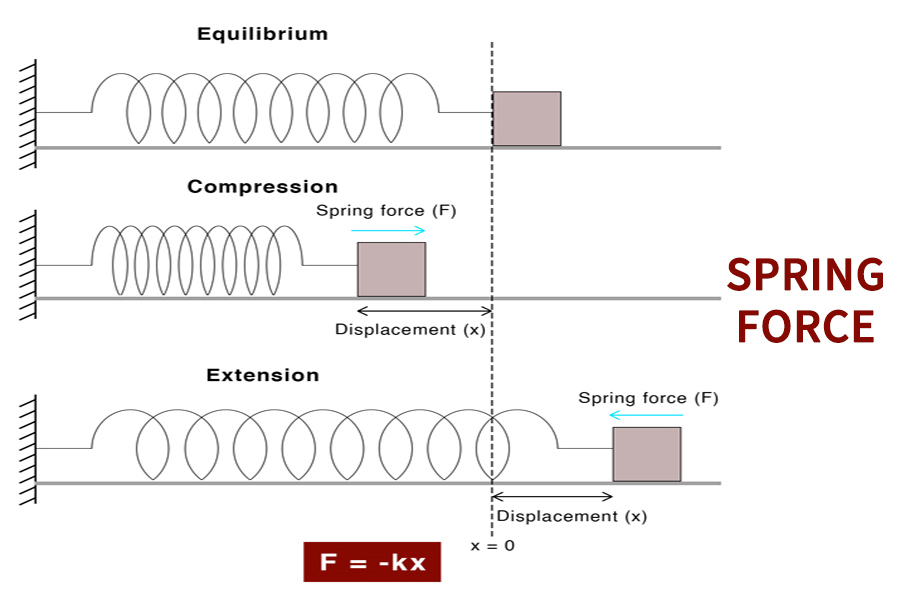

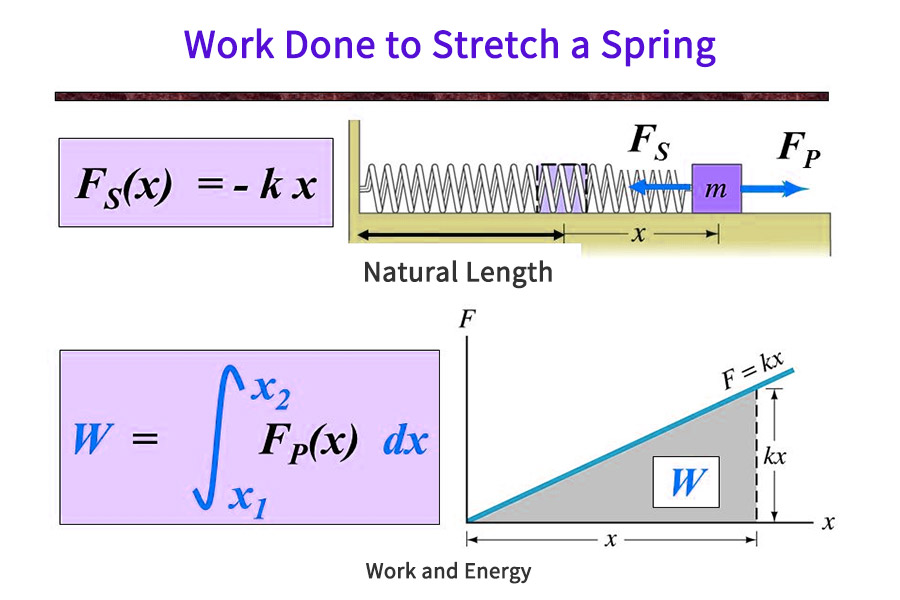

Hooke’s Law: Understanding the Principle of Springs

Hooke’s Law describes the force needed to compress or extend a spring: F=−kXF = -kX

- F: Force exerted by the load on the spring

- X: Spring displacement

- k: Spring constant

What are the Types of Mechanical Springs?

1. Compression Springs

- Function: Store and release energy when compressed

- Applications: Pens, garage doors, vehicle suspension systems

2. Extension Springs

- Function: Store energy when stretched

- Applications: Garage doors, trampolines, toys

3. Torsion Springs

- Function: Store energy through twisting

- Applications: Clothespins, spring hinges, clock springs

4. Constant Force Springs

- Function: Provide a constant force

- Applications: Retractable cords, tape measures

Characteristics of Mechanical Springs

Compression Springs

- Various shapes

- High elasticity

- Strong load capacity

- Long life

- Easy to install

Extension Springs

- Elongation and elasticity

- Strength and durability

- Various end shapes

Torsion Springs

- Mitigate impact and absorb vibration

- Control mechanism movement

- Store energy

Constant Force Springs

- Constant mechanical properties

- High-precision control

- Long life and durability

- Customizability

How Do Mechanical Springs Work?

Compression Springs

Store energy when compressed and release it when the force is removed.

Extension Springs

Absorb and store energy as they stretch, generating a restoring force.

Torsion Springs

Store energy through twisting and return to their original shape when the force is removed.

Constant Force Springs

Store energy through elastic deformation, providing a constant force.

Common Applications of Mechanical Springs

Compression Springs

- Medical equipment

- Electronics

- Precision instruments and tools

- Industrial equipment

- Toys

- Mattresses

Extension Springs

- Garage doors

- Automobiles

- Trampolines

- Toys

- Medical devices

- Farm equipment

- Fence gates

Torsion Springs

- Clothespins

- Spring hinges

- Clock springs

- Torsion bar suspension

Constant Force Springs

- Balancers

- Door closers

- Cable retractors

- Hose retrievers

- Exercise equipment

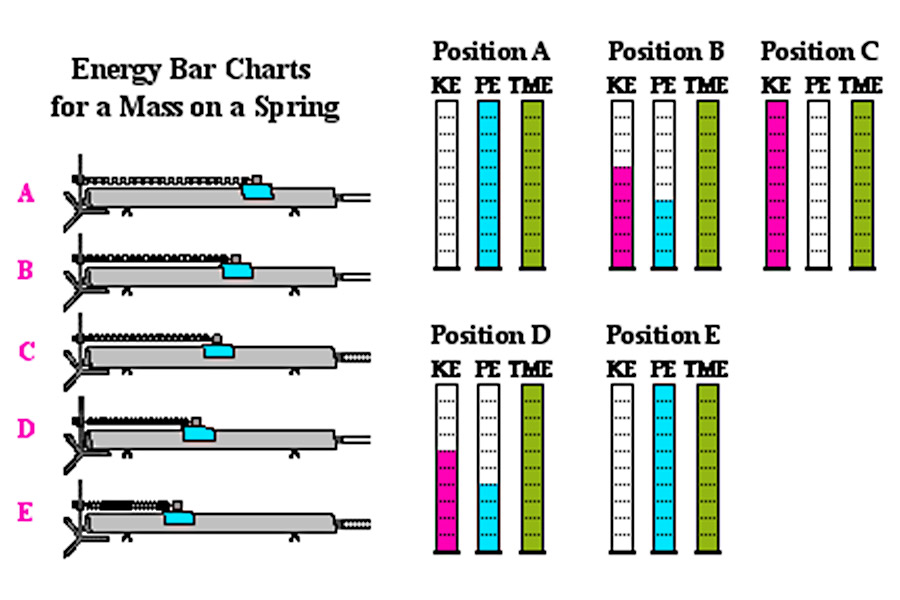

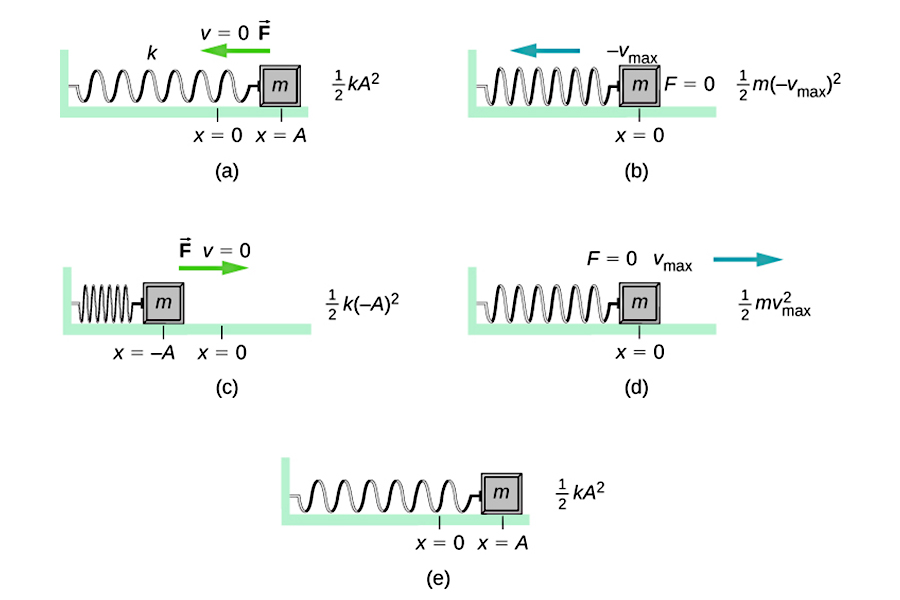

Spring Energy Dynamics

The spring constant (k) and elastic potential energy formula (PE=1/2kx2PE = 1/2kx^2) help determine how much potential energy a spring can store.

How Do Mechanical Springs Store Energy?

- Tension Springs: Store energy through tensile deformation.

- Compression Springs: Store energy through compression.

- Torsion Springs: Store energy through twisting.

- Constant Force Springs: Store energy through elastic deformation.

Common Materials for Custom Mechanical Springs

| Material | Examples |

|---|---|

| Aluminum Alloy | 6061, 5052, 2A12, 7075 |

| Stainless Steel | 303, 304, 316, 420, 17-4PH |

| Alloy Steel | Q235, 45 steel, Cr12, 3Cr13 |

| Copper Alloy | Bronze-H59, Bronze-H62, T2 |

| Other Alloy | Titanium-TC4, Magnesium-AZ91D |

Advantages and Limitations of Spring Energy Storage

Advantages

- High energy density and efficiency

- High reliability and stability

- Long life

- Environmental protection and energy saving

- Diversified applications

Limitations

- Relatively low energy density

- Limited lifespan

- Largely affected by the environment

- Limited energy storage and release speed

Why Choose Longsheng Mechanical Spring Manufacturing?

Longsheng offers advanced mechanical spring manufacturing equipment and complete testing equipment to meet various needs. They provide high precision CNC machining services with certifications like ISO 9001, ISO 14001, and IATF 16949.

Conclusion

Mechanical springs are vital for storing and releasing energy in various applications. Understanding their types, characteristics, and functions is crucial for selecting the right spring for specific needs. Partnering with a proficient CNC machining parts factory specializing in aluminum CNC machining, CNC plastic machining, CNC titanium machining, multi-axis CNC machining, and high precision CNC machining ensures the best results for your project.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

What are the reasons for using mechanical springs?

Mechanical springs provide elasticity, versatility, cost-effectiveness, and are widely used in various industries for absorbing and distributing energy.

How do springs store energy in clocks and car suspension systems?

Springs in clocks store energy through twisting, driving movement, while car suspension springs absorb and release energy from road impacts.

Can mechanical springs be customized?

Yes, mechanical springs can be customized by modifying parameters such as wire diameter, coil pitch, number of coils, and material selection.

What impact do new materials and designs have on spring performance?

New materials and designs can significantly improve spring performance by enhancing strength, elasticity, corrosion resistance, and life.