In today’s rapidly developing manufacturing field, low volume injection molding has become the focus of many enterprises because of its flexibility and diversity. However, for many start-ups and small manufacturers, how to reduce the cost of low volume injection molding while ensuring product quality is a big challenge for them. This paper aims to explore the optimization strategy for the cost of low volume injection molding and how to minimize the cost in China.

What Is Low Volume Injection Molding?

Low volume injection molding is the optimal manufacturing technique for producing fewer than 100,000 units of a given component. Before committing to a long-term molding setup, it is used to mass-produce identical components; however, certain low volume plastic parts may never need larger-scale manufacturing; therefore, it is utilized before making such a commitment. This molding is one of the most prevalent techniques used in the current manufacture of plastics.

low volume injection molding vs traditional injection molding

The production rate is one of the most distinguishing features of low volume injection molding compared to traditional injection molding. Traditional injection molding requires much more time than low volume injection molding.

Additionally, the mold designs for conventional injection molding are more complex, which may increase the time necessary to create the components. Due to this, preferring low volume injection molding over more typical methods has many advantages.

| Aspect | Low Volume Injection Molding | Traditional Injection Molding |

| Production Quantity | Low quantities | High quantities |

| Tooling Cost | Lower cost | Higher cost |

| Lead Time | Shorter lead time | Longer lead time |

| Setup Time | Faster setup | Longer setup |

| Design Flexibility | High | Moderate |

| Waste Generation | Less waste | More waste |

| Complexity of Parts | Suitable for complex parts | Suitable for complex parts |

| Sustainability and Environmental Impact | Generally more sustainable | Potential environmental impact |

| Maintenance and Repairs | Easier to maintain | Complex maintenance |

| Customization Possibilities | High | Limited |

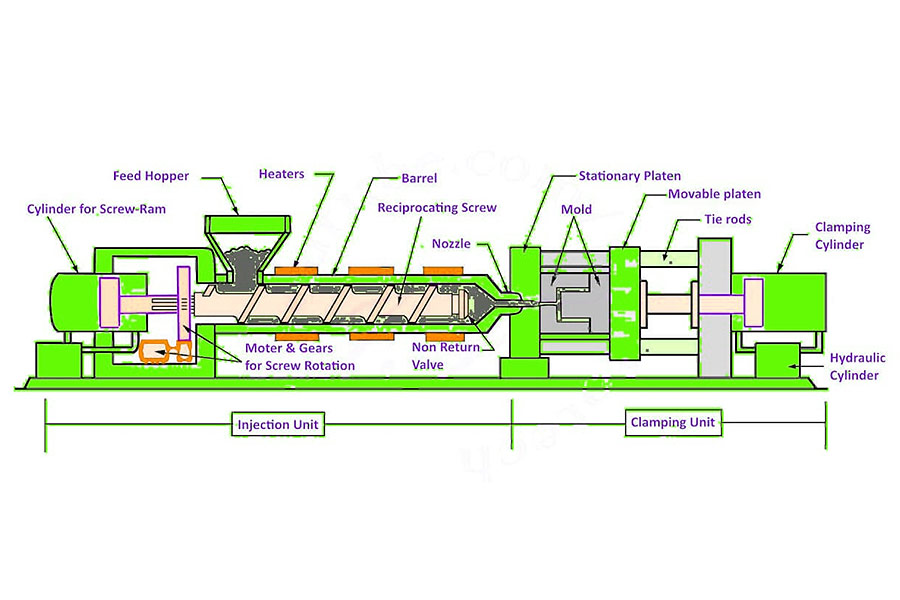

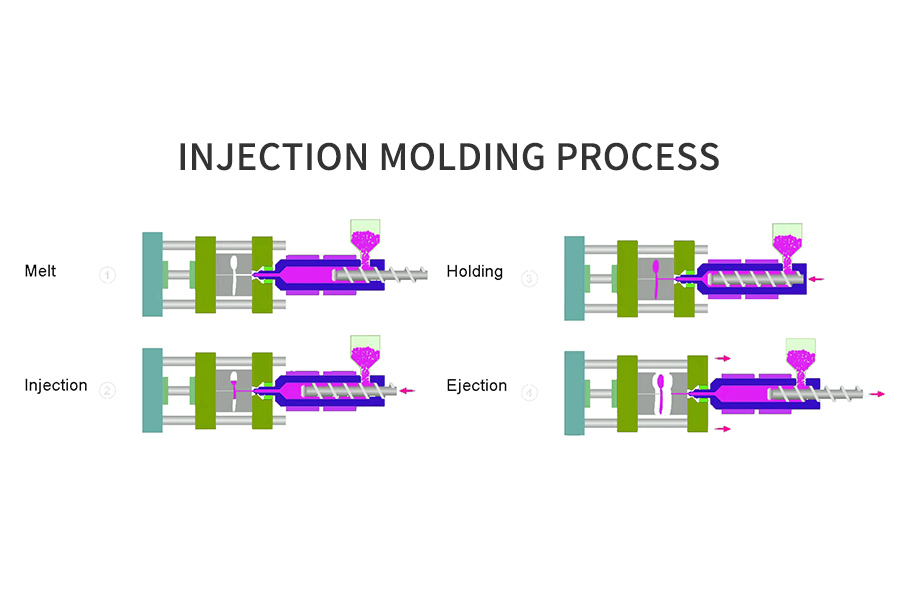

Step-by-Step Workflow for Low-Volume Injection Molding

The workflow for low-volume injection molding includes the following seven steps:

1. Mold Design

Design the mold for your part in the CAD software of your choice. Adhere to common design rules for additive manufacturing and injection mold design. Design recommendations specific to polymer 3D printed molds can be found in our whitepaper.

Upload your design into PreForm, Formlabs print preparation software. Prepare your print and send it to your Formlabs 3D printer.

2. Mold 3D Printing

Choose a 3D printing material and begin your print. Rigid 10K Resin at 50 micron layer height is an ideal choice for most mold designs as it combines high strength, stiffness, and thermal resistance.

When possible, it is advised to print the mold flat, directly on the build platform without any supports, in order to reduce warpage.

After washing and post-curing, your 3D printed mold is ready to be integrated into your injection molding process.

3. Mold Assembly

Prior to assembly, you may choose to finish the mold to meet critical dimensions with hand-sanding, desktop or CNC machining.

It is recommended to place the printed mold inside a standard metal frame, or a Master Unit Die, to support against high pressures and extend the lifetime of your printed mold. Carefully assemble the 3D printed mold inside the metal frame. Add ejector pins, inserts, side-action parts, and other components as needed.

Install the assembled mold in your injection molding machine.

4. Mold Clamping

Insert the plastic pellets, input the required settings, and begin production. A lower clamping force is suggested, particularly if the printed mold is not protected by a metal frame.

A broad range of thermoplastics can be injected with 3D printed molds such as TPE, PP, PE, ABS, POM, ASA, PA, PC, or TPU.

5. Injection

It may take a few shots to identify your ideal process conditions as many factors are at play including part geometry, choice of plastic, injection temperatures and pressures, and other parameters.

Reduce injection pressure and temperature as much as possible.

With one printed mold, Formlabs users are usually injecting 100s of parts in easy-to-process plastics such as TPE, PP, and PE with temperatures up to 250°C. With plastics that require higher injection temperature such as PA or PC, the 3D printed mold might have a shorter lifespan.

Read our process conditions documentation to see test results with both desktop and industrial injection molding machines.

6. Cooling

The cooling time of a polymer printed mold is longer than that of a metal mold, as thermal transfer occurs slower in plastic than metal. As such, adding cooling channels to your printed mold is generally not suggested.

Instead, cooling can be accelerated by applying compressed air to cool the mold, or using interchangeable stacks.

7. Demolding

Demold the part either manually or automatically with ejector pins. Apply a release agent for thermoplastics with high viscosity. Mold releases are widely available and silicone mold releases, such as Slide or Sprayon products, are compatible with Formlabs Resins.

Benefits Of Low Volume Plastic Injection Molding

- Cost-effective: Low volume plastic injection molding is more cost-effective than other manufacturing methods like 3D printing or CNC machining, especially when producing small quantities of parts.

- High-quality parts: Injection molding creates high-quality parts with tight tolerances and excellent surface finishes. Parts produced through injection molding are also stronger and more durable than those produced through other manufacturing methods.

- Fast turnaround time: Injection molding allows for fast production times, meaning your parts can be produced quickly and with minimal downtime.

- Reduce material waste: Wasting materials is not only harmful to the environment, but also brings high costs to the business. With low-volume injection molding, you can produce only the number of parts you need, minimizing excess inventory and material waste. This sustainability is not only environmentally conscious but also helps make the production process more efficient and cost-effective.

- Customized services: Modern consumers crave personalized and customized products. Low volume injection molding meets this need perfectly, allowing you to create custom products, specialized components and unique designs. This level of customization is valuable for carving out niche markets and catering to the varying preferences of consumers seeking differentiated products.

- Reduce Risk: There are inherent risks in launching new products, including market acceptance and unforeseen design flaws. Low-volume injection molding is a risk mitigation strategy. By producing a limited number of parts, you can try it out first, see how customers respond, and identify any potential issues before scaling up. This approach minimizes potential losses from producing large quantities of defective products.

- Suitable for small and medium-sized enterprises: While large enterprises can bear the upfront costs of traditional injection molding, small and medium-sized enterprises often face financial constraints. With low-volume injection molding, the manufacturing process becomes more inclusive, allowing SMEs to compete on a level playing field by lowering the barriers to entry. This accessibility fosters innovation and diversity in the industry.

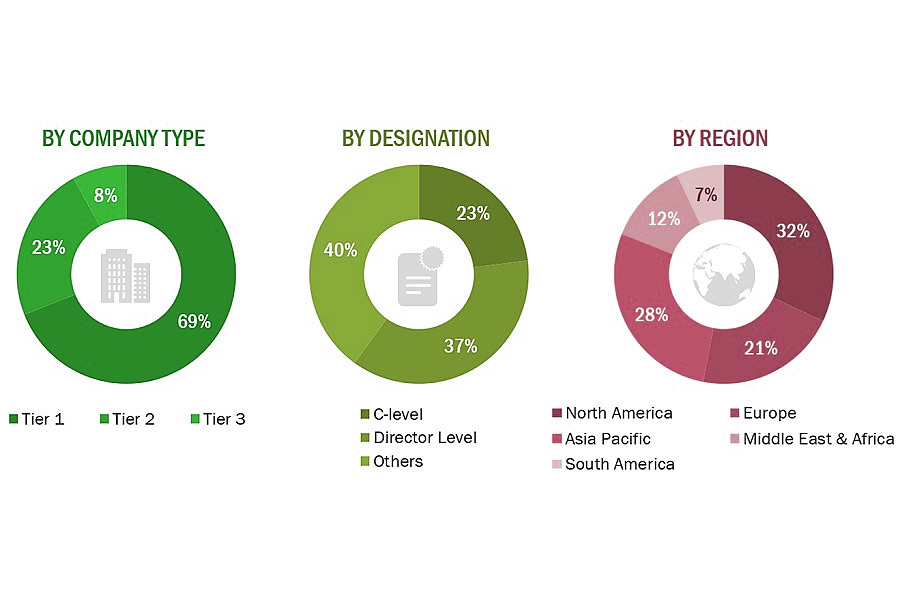

How to choose a low-cost injection molding manufacturer?

Choosing the right low-cost injection molding manufacturer can be difficult because companies must consider many factors. Here are some points to help you make the right decision:

Experience

Look for a supplier with a proven track record of success in low-volume injection molding. An experienced supplier may have the expertise and skills to deliver a high-quality product.

Quality Control

Quality control is crucial in injection molding as even minor defects can lead to significant production delays and costs. Make sure the supplier has a strong quality control system in place to ensure the final product meets your specifications.

Customization

Injection molding can create a variety of products, from small components to large parts. Find a supplier who can tailor services to meet your needs, including material selection, mold design and production volumes.

Communication

Good communication is the key to a successful injection molding project. Look for a supplier that is responsive, easy to communicate with, and keeps you informed throughout the entire production process.

Cost

Cost is always a consideration, but it should not be the only factor. Look for suppliers that offer competitive prices while still providing high-quality products and excellent customer service.

Environmental Responsibility

As environmental issues become increasingly important, it is critical to select suppliers who are committed to sustainable manufacturing practices. Look for suppliers that use environmentally friendly materials and processes and recycle waste materials.

What factors affect the cost of low volume injection molding?

Mould Design

Mold design plays a crucial role in the final cost of the injection molding project. Mold can be simple or complex, the more complex, the more expensive the mold. For example, a mold with multiple types of chambers costs more than a single cavity mold.

Mold Materials

Materials used for molding also have an impact on the cost. Different types of plastics have different costs, and some materials are better than others for some uses. Material selection determines the required stiffness, durability, and heat resistance of the components.

Part Size And Complexity

In general, smaller and less complex parts are cheaper to produce for larger and more complex parts. The amount of the cavity in the mold also affects the cost- -the larger the cavity means that more parts can be made in each molding cycle, which reduces the cost of each part.

Material Selection

The material used for molding will impact the cost as well. Different types of plastics have different costs, and some materials are better suited for certain applications than others. Material selection will depend on factors such as the part’s required stiffness, durability, and heat resistance.

Production Volume

As I said earlier, the larger the production, the smaller the cost. But balancing production and demand is important for ── Manufacturing more than required components with unnecessary costs.

Labor Costs

The complexity of the components and the level of skill the workers require can determine labor costs. So know how to reduce labor costs and increase productivity. It is worth noting that labor costs can vary far from using custom injection molding.

Shipping And Overhead Expenses

The additional costs we have to consider include transportation and administrative costs, such as electricity, rent, insurance, etc.

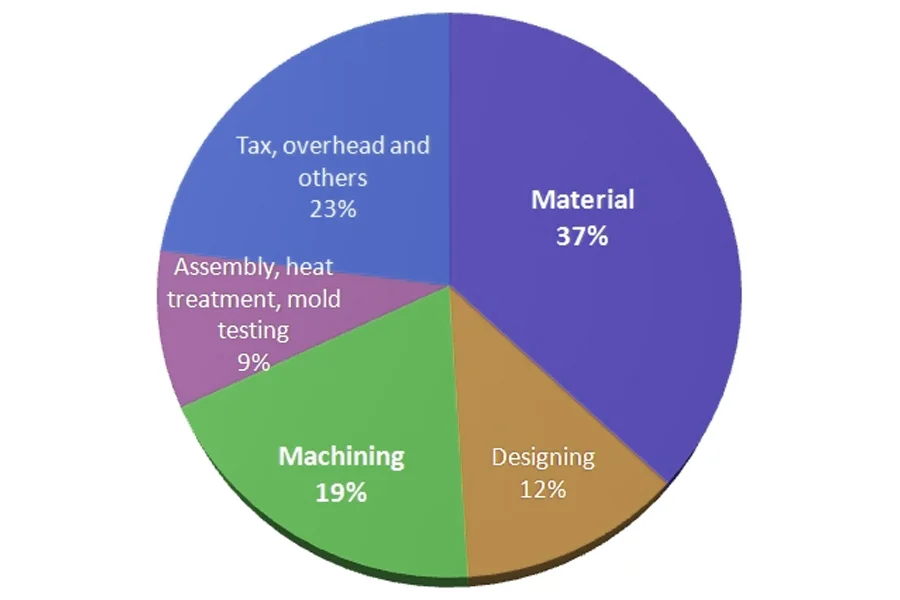

low volume injection molding cost structure

This section introduces the various costs associated with low volume injection molding. We’ll dive into all aspects of low-volume injection molding costs, including how these factors can impact your business and what you can do to save on low volume injection molding costs. Then let’s dive into the cost of low volume injection molding!

When it comes to low volume injection molding, there are several types of costs you need to pay attention to. The main costs are listed below:

- Material Cost: The cost of raw materials used in the injection molding process is one of the most critical factors affecting the overall cost of low-volume injection molding. Prices for materials may vary depending on quality, size and order quantity.

- Labor Cost: The cost of providing labor during the injection molding process is another key factor that affects the overall cost. Labor costs include wages for maintenance personnel, machine operators and other employees within the plant.

- Energy costs: The cost of energy used in low-volume injection molding is also an important factor affecting the overall cost. Energy costs can vary depending on the type of production process, temperature control settings and other factors.

- Equipment Cost: The cost of purchasing and maintaining injection molding equipment is another important cost factor.

- Mold Expenses: The cost of designing, developing and manufacturing injection molds is another important cost factor.

- Overhead expenses: Overhead expenses include all expenses not directly related to the injection molding process. These costs include rent, insurance, taxes and other charges.

Money Saving Tips

- Select the appropriate mold structure: Selecting the appropriate mold structure to reduce costs requires consideration and implementation from many aspects. By in-depth understanding of product requirements, avoiding complex mold structures, selecting mold types according to product characteristics, optimizing mold material selection, considering the maintenance and upkeep of molds, cooperating with suppliers, and introducing new technologies and processes, molds can be effectively reduced. costs and improve product competitiveness.

- Select materials with the right price: by clarifying project requirements and budgets, conducting market research and comparisons, considering the long-term cost of materials, considering the substitutability of materials, establishing long-term cooperative relationships with suppliers, optimizing procurement strategies, and considering the environmental protection and Sustainability and other measures can effectively reduce material costs and improve the economic benefits of the project.

- Optimize product design: Making injection molded parts smaller can increase production and reduce the cost of each part. Undercuts and intricate details increase tooling costs and processing time and should be avoided. The use of multi-cavity molds can produce multiple parts at the same time, improving production efficiency.

- Bulk orders: Through the implementation of measures such as reasonable planning of batch sizes, establishing long-term cooperative relationships with suppliers, taking advantage of bulk purchasing, optimizing inventory management, considering transportation costs, considering raw material price fluctuations, improving production efficiency, and continuous monitoring and adjustment, you can Effectively reduce the cost of small batch injection molding and improve the economic benefits and market competitiveness of enterprises.

How low volume Injection Molding Cost Calculators Work

The low volume injection molding cost calculator is an online computing tool that allows you to accurately estimate injection molding costs. They can take into account various factors affecting the cost of low volume injection molding. Some calculators require additional information, such as mold design, runner systems, and cycle times, to provide a more accurate estimate.

Once you enter the information you need, the calculator produces a price estimate. Estimates may include mold cost, material cost, and production cost per component. Some calculators also provide a breakdown of the costs for each component. The results of the calculator will cause you to think about how much your injection molding project will cost, and how much you can make the best choices on your budget.

How much is the cheapest low volume injection molding cost in china?

Estimating small batch injection molding costs:

Take a hypothetical simple case as an example, assuming the use of ABS plastic (1.8 yuan/g), a simple mold (cost assumed to be 50,000 yuan), a 50-ton injection molding machine (80,000 yuan), two operators (monthly The salary per person is 4,000 yuan), and the monthly energy and other expenses total 20,000 yuan.

- Plastic raw material cost: Assuming that each injection molded part weighs 10 grams, the material cost is 10 grams * 1.8 yuan/gram = 0.18 yuan/piece.

- Mold apportioned cost: Assuming the service life of the mold is 100,000 times, the apportioned cost each time is 50,000 yuan/100,000 times=0.5 yuan/unit.

- Injection molding machine cost apportionment: Assuming that the injection molding machine has a service life of 10 years and produces 10,000 times per year, the cost apportionment each time is 80,000 yuan/10 years/10,000 times = 0.8 yuan/unit.

- Labor cost: The total monthly salary of two operators is 8,000 yuan. Assuming 10,000 production times per month, the labor cost per piece is 8,000 yuan/10,000 times = 0.8 yuan/piece.

- Energy and other cost sharing: Assuming 10,000 production times per month, the shared cost per piece is 20,000 yuan/10,000 times = 2 yuan/piece.

Based on the above cost calculation, the cost of each injection molded part is roughly 0.18 yuan (material) + 0.5 yuan (mold) + 0.8 yuan (machine) + 0.8 yuan (labor) + 2 yuan (energy and others) = 4.28 yuan/piece.

This is only a very rough estimate and actual costs may vary on a case-by-case basis. For example, factors such as the service life of the mold, the actual running time of the injection molding machine, production quantity, fluctuations in raw material prices, etc. will all affect the final cost.

Common Challenges in Low Volume Injection Molding

Meeting these challenges in low volume injection molding requires a thorough understanding of project requirements, close collaboration with suppliers and partners, and continuous process improvement.

- Mold Cost: Low volume injection molding typically involves smaller production runs, making upfront mold costs a significant challenge. The cost of designing and manufacturing tooling per part can be higher than high volume production, so careful cost analysis and optimization is required.

- Design Complexity: Low volume production can involve complex and intricate designs. The challenge is to ensure that the method is feasible for injection molding and that the mold accurately reproduces the required geometry. Design modifications and iterations may be required to achieve optimal results.

- Material selection: Choosing the right material for low volume injection molding can be challenging. We have to consider cost, functionality, durability and usability. Finding a balance between material properties and project requirements is critical to achieving the required quality and performance.

- Part quality consistency: Maintaining consistent part quality during low volume production can be challenging. Changes in process parameters, tool wear and material properties can affect part dimensions, surface finish and mechanical properties. Strict quality control measures and continuous monitoring are necessary to reduce variation.

- Lead time: Low volume injection molding typically requires shorter lead times than high volume production. Effective planning and coordination are essential to optimize production schedules, minimize time and ensure timely delivery of parts. Effective communication with suppliers and partners is critical to meeting strict timelines.

- Scalability limitations: Low mold injection molding processes may have limitations in terms of scalability. The interface from low volume production to high volume production may require tooling, equipment, and process adjustments. Anticipating scalability challenges and planning for future production needs is critical.

- Cost per part: Low volume injection molding tends to cost more per part than high volume production because we spread the tooling costs over smaller parts. Balancing cost considerations while maintaining quality standards and meeting project requirements is critical.

- Risk of Obsolescence: Low volume production often caters to a niche market or a specific product variant. The risk of obsolete parts or fluctuating demand can pose challenges. Careful market analysis, demand forecasting and inventory management strategies are necessary to minimize the risk of obsolescence.

Future Outlook: Development Trend of Low volume Injection Molding Machines

The future of low-volume injection molding machines is bright, and several trends are impacting the industry. Here are some key trends to watch in low volume injection molding:

- Additive Manufacturing Adoption Rising: The integration of additive manufacturing, such as 3D printing, into low volume injection molding will continue to grow. Additive manufacturing allows for rapid prototyping, tool production and customization, reducing time to market and increasing design flexibility.

- Sustainable and bio-based materials: As sustainability becomes more of a priority, the use of sustainable and bio-based materials in low-volume injection molding will increase. Manufacturers will explore environmentally friendly alternatives to traditional plastics to reduce environmental impact and meet consumer preferences for sustainable products.

- Customization and personalization: Consumers increasingly seek personalized products tailored to their specific needs. . Low volume injection molding will tap into this trend by offering customization options, allowing customers to design and order unique parts with personalized features, colors or branding.

- Design optimization and simulation: Advanced design optimization and simulation tools will play an important role in low-volume injection molding. These tools will enable manufacturers to analyze part designs, predict manufacturing challenges, optimize mold designs and reduce the need for costly trial and error.

- Regulatory Compliance and Quality Assurance: As regulatory requirements continue to increase, small batch injection molding will focus on maintaining compliance and improving quality assurance measures. Manufacturers will implement strict quality control processes, traceability systems and documentation to meet regulatory standards and customer expectations.

Why choose Longsheng’s Low Volume injection molding service?

At Longsheng, we specialize in providing low volume injection molding services for various industries such as automotive, electronics, and medical. We offer a variety of materials (including ABS, PC, PP, and more), color options, and finishes to meet your specific needs. Our experienced team will work closely with you to determine the best solution for your unique needs, ensuring your parts are produced quickly, efficiently, and to the highest quality standards.

We understand that no two projects are the same, which is why we offer a range of services to meet your specific needs. Whether you need help with design, prototyping, or low volume production, we have the expertise and resources to help you get the job done.

Low volume plastic injection molding services are the ideal solution for small businesses looking to produce high-quality plastic parts without breaking the bank. Longsheng’s low volume injection molding services offer fast turnaround times, high-quality parts, and a range of materials and finishes to meet your unique needs. Contact us today to learn more about how we can help you achieve your production goals.

conclusion

The cheapest small batch injection molding cost in China is a relatively complex issue because it is affected by many factors, including the model of the injection molding machine, the cost of plastic raw materials, mold fees, the number of injection molding processes, labor costs, and other expenses such as water and electricity , transportation, etc.). Due to the variety of these factors, it is difficult to give an exact “cheapest” value. However, we can reduce the cost of small-batch injection molding production and improve the competitiveness of enterprises by choosing appropriate mold structures, selecting materials with appropriate prices, optimizing product design, and placing batch orders.

FAQs

What is the price range for low volume injection molding?

Prices for low volume injection molding can range from a few cents to thousands of dollars per piece, depending on factors such as product complexity, production volume, mold and equipment costs, regional differences and whether additional services are included. Therefore, when choosing injection molding services, customers are advised to engage in detailed communication and negotiation with suppliers to ensure they receive the solution that best suits their needs and budget.

How long does the small volume injection molding machine process usually take?

The duration of the low-volume injection molding machine process depends on factors such as part complexity, material selection, and mold manufacturing. However, it generally offers faster production times than traditional injection molding.

Can a small-capacity injection molding machine accommodate complex part designs?

Small volume injection molding machines are ideal for complex part designs. Its design flexibility allows complex geometries, undercuts and thin walls to be produced with high precision

What are the advantages of low volume injection molding machines for start-ups and small businesses?

Low volume injection molding machines provide start-ups and small businesses with a cost-effective manufacturing solution that reduces upfront costs and shortens production times, allowing them to bring products to market more efficiently.

Pingback: High-Speed Prototype Machining Services | Low-Volume Manufacturing for Prototypes

Pingback: Industrial Rapid Prototyping Services | 3D Printing vs. CNC Prototyping