Precision molds are of irreplaceable importance in the plastic injection molding process. They are not only the key to ensuring product quality and performance, but also an important tool to improve production efficiency, reduce costs and promote product innovation. With the continuous advancement of science and technology and the continuous development of manufacturing industry, the importance of precision molds will become more prominent.

In this blog, Longsheng will take you to learn and discuss the various types of molds used in plastic injection, key design considerations for precision molds, manufacturing methods of precision molds, the benefits of precision molds, and the emphasis on strict tolerances and quality control in Achieve consistent and precise effects in plastic parts and more, ensuring you don’t feel lost when choosing a plastic mold injector manufacturer. Let’s start the next learning journey!

What’s Injection Molding?

The injection molding course makes the specified parts or merchandise by injecting the molten materials into an injection mold below stress. The molds comprise cavities based on the geometry of the intended form. Upon cooling, the fabric solidifies into the specified form. Lastly, opening the mold and injecting the solidified parts completes the method. Nevertheless, generally, molded parts require post-machining or floor-ending remedies to satisfy the required specs.

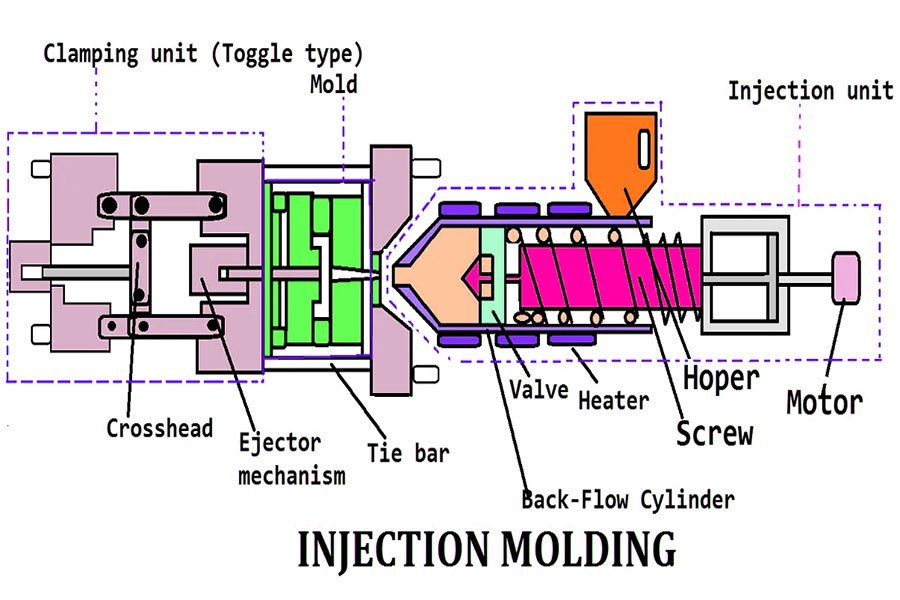

The plastic molding course’s setup includes three models: mold, Injection, and Clamping unit.

Firstly, Injection Mould consists of two halves that come collectively to type the cavity into which the molten materials are injected. Secondly, the injection unit heats and injects the fabric into the mildew. It melts the plastic pellets and forces the liquid into the mildew cavity via stress. Thirdly, the clamping unit holds the mildew halves tightly collectively through the injection and cooling. As soon as the fabric solidifies, the clamping unit opens the mildew to eject the half.

Advantages of Injection Molding

- This method is economical for large-scale manufacturing runs, as mildew is usable for several thousands to tens of millions of manufacturing cycles under correct upkeep.

- It molds supplies into advanced shapes with precision. It is dependent upon the cavity intricacies.

- A single mildew is relevant for several molding cycles. So, it produces parts with uniform precision and high quality, guaranteeing excessive effectivity and repeatability.

Disadvantages of Injection Molding

- In contrast to CNC machining, it includes making a mildew first earlier than precise manufacturing. It makes injection molding costlier in CNC machining vs injection molding comparability.

- Not all supplies are appropriate for injection molding. It’s generally splendid for thermoplastic parts. Subsequently, the mildew design should accommodate the capabilities of molding machines, limiting inventive flexibility.

- Growing and producing molds takes time. It could lengthen the general timeline from idea to manufacturing, affecting undertaking schedules.

How does the plastic injection molding process work?

Step 1: Choose the right thermoplastic and mold

Selecting the appropriate thermoplastics and plastic injection molds is critical as they are essential elements in manufacturing and forming the final part. Over the past decade, considerable progress has been made in the study of the interaction between thermoplastics and plastic molding. In fact, manufacturers must think deeply about the interaction between thermoplastics and molds when making selections, because some plastic types may not be suitable for specific mold design needs.

The mold tool is composed of two main parts: the mold cavity and the mold core. Mold tools have one or several punches that cooperate with other parts to achieve different functions. The mold cavity serves as a stable part for the plastic to be injected into, while the mold core is a movable part that can be placed inside the mold cavity to help shape the final form of the component. Depending on the specifications, mold tools can be designed to manufacture multiple or more complex parts.

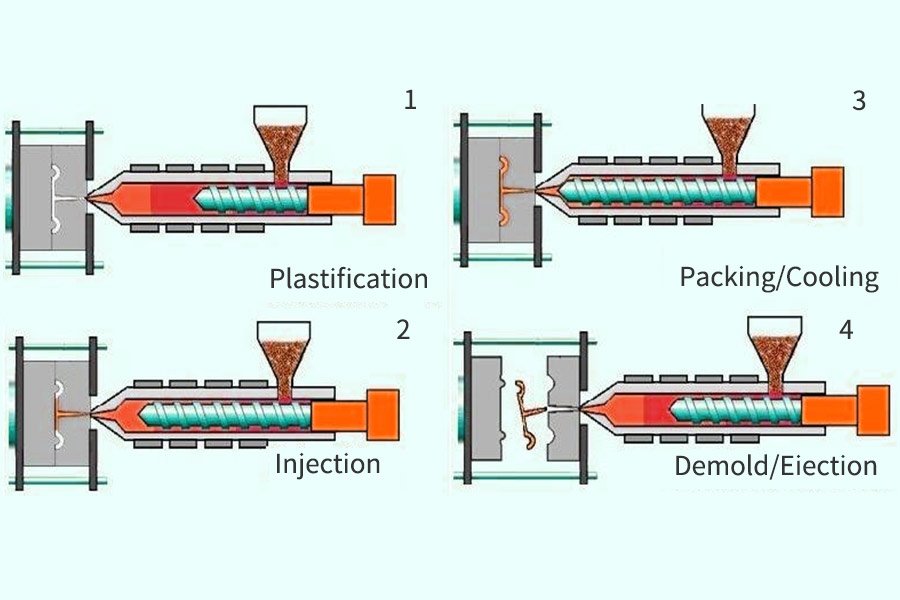

Step 2: Feed and Melt Thermoplastic

Injection molding machines can be driven by hydraulics or electricity, and electric injection molding machines can replace traditional hydraulic machines, which reduces production costs and energy consumption to a great extent. This method is to extrude the molten plastic from the mold and turn it into pellets with a certain shape during its cooling stage. To start the process, initial plastic pellets of thermoplastic material are introduced into the top hopper of the machine. Due to the formation of a spiral flow in the screw, the polymer sent from the hopper is continuously extruded into the die.

When the screw starts to rotate, the batch of plastic particles is gradually transported into the barrel of the machine. There is a heat exchange device composed of a heater between the barrel and the hopper to maintain the thermal state inside the barrel. The rotation of the screw and the heat generated by the barrel gradually heat the thermoplastic to its melting point until it transforms into a molten mass. Subsequently, when the extrudate is cooled, the product in the desired shape is obtained. In this process, maintaining the right temperature is a core element to ensure that the plastic can be injected efficiently and that the plastic parts can be accurately formed during the injection molding process.

Step 3: Inject plastic into the mold

Once the molten plastic reaches the end of the barrel, the gate closes and the screw moves backwards. This draws in a certain amount of plastic and builds pressure in the reciprocating screw, ready for injection. At the same time, the mold halves are closed together and held under high pressure, called clamping pressure.

Injection pressure and clamping pressure must be balanced to ensure the part forms correctly and no plastic escapes from the tool during the injection process. Once the tool and screw reach the correct pressure, the gate opens, the screw moves forward, and molten plastic is injected into the mold.

Step 4: Hold and Cooldown Time

When most plastics are injected into a mold, they maintain a steady pressure for a specific period of time. It varies depending on the type of thermoplastic and the complexity of the part, with times ranging from milliseconds to minutes. Make sure the plastic fills the mold and shapes out the core accurately and that it holds it for a long time. After reaching hold, the screw shrinks again, releasing pressure and allowing the component to cool within the mold, allowing the plastic to solidify. Known as the “cooldown time,” this time span can last from a few seconds to a few minutes, while ensuring that the ejection and complete completion of each part on the production line are properly set.

How Precision Mold Manufacturing Enhances Plastic Injection Molding?

1.Optimize mold design

Through accurate three-dimensional modeling and simulation analysis, the rationality and accuracy of mold design are ensured, thereby reducing time and costs in manufacturing and debugging. Optimize the design of the main channel, runner and gate to ensure that the molten plastic can enter the mold cavity evenly and quickly, reducing injection pressure and filling time. By adding reinforcement ribs, optimizing wall thickness distribution and other measures, the strength and stiffness of the mold can be improved and deformation and wear can be reduced.

2.Choose high-quality materials

Use wear-resistant, corrosion-resistant, high-strength mold steel, such as P20, 718H, etc., to improve the durability and accuracy of the mold. Select plastic raw materials with high mechanical properties, dimensional stability, and good creep resistance to ensure the quality of injection molded products.

3.Fine manufacturing process

High-precision processing equipment such as CNC machining centers and EDM machines are used to ensure dimensional accuracy and surface quality during the mold manufacturing process. Through precise assembly processes, the matching accuracy between the various parts of the mold is ensured and the impact of assembly errors on injection molding is reduced.

4.Optimize injection molding process

According to the characteristics of plastic raw materials, mold structure and product requirements, parameters such as injection molding temperature, pressure, speed and so on are reasonably set to ensure the stability of the injection molding process and the quality of the product.

5.Strengthen production control

Implement strict quality control processes to monitor and test all aspects of mold manufacturing and injection molding to ensure product quality meets standards. Use data analysis tools to monitor production data, promptly discover and solve production problems, and continuously optimize production processes and process parameters.

6.Regular maintenance and upkeep

Clean and lubricate the mold regularly to reduce wear and clogging and keep the mold in good working condition. Regularly check the wear and damage of the mold, repair and replace it in time, and extend the service life of the mold.

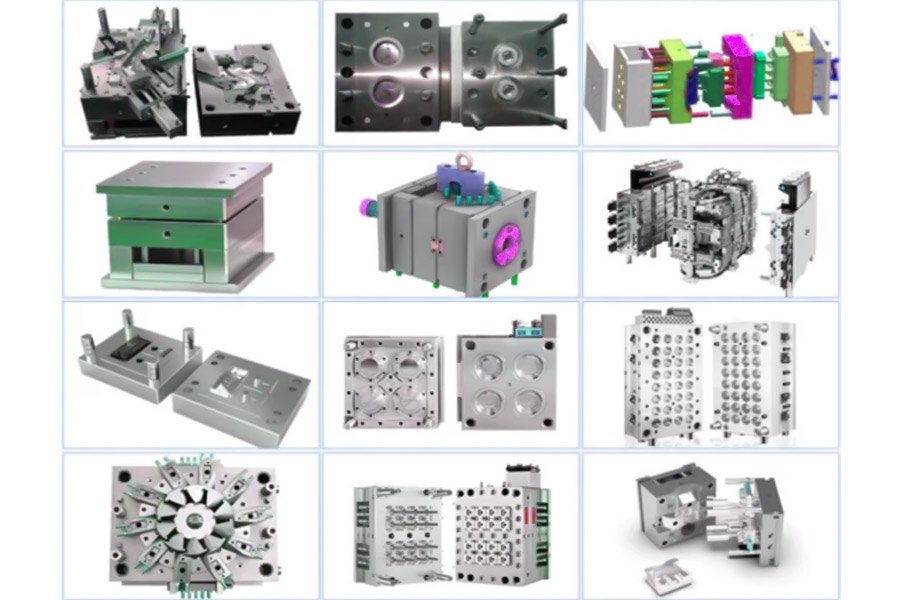

What are the types of precision molds?

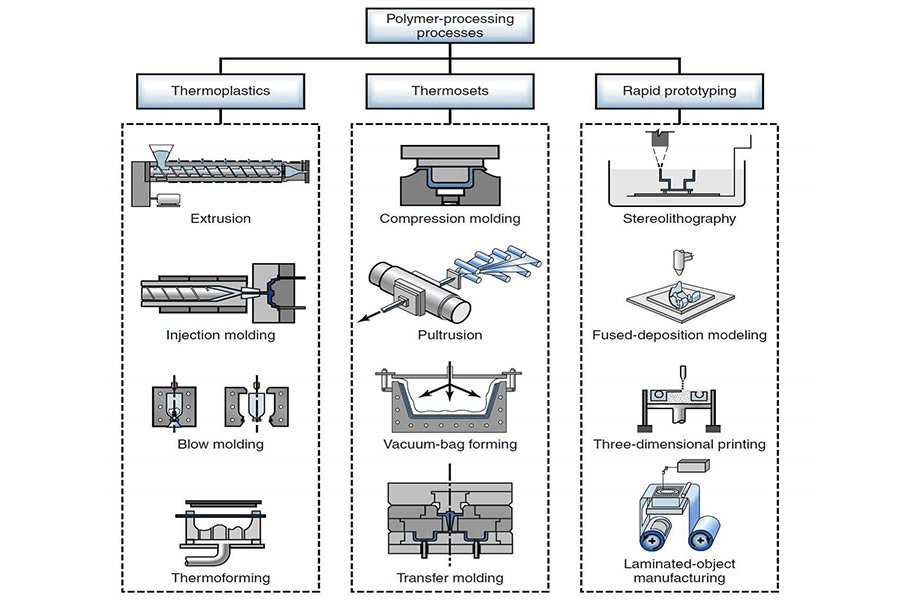

In the plastic injection molding process, mold selection and design are crucial, and they directly affect product quality and production efficiency. Commonly used mold types in plastic injection include injection molds, compression molds and transfer molds.

√Injection mold

Injection molds are the most commonly used mold type in plastic injection molding. Its working principle is that molten plastic is injected into the cavity of the mold under high pressure, and is cooled and solidified to form the desired product shape. Injection molds usually consist of two parts: a movable mold and a fixed mold. The movable mold is installed on the moving template of the injection machine, and the fixed mold is installed on the fixed template.

√Compression mold

Compression molds differ from injection molds in their molding principles. In compression molding, plastic raw materials are placed in an open mold cavity, and then the mold is closed and pressure is applied, so that the plastic fills the cavity and solidifies under the action of heat and pressure. Compression molds are usually used to manufacture plastic products with complex shapes, uneven wall thickness, or deep cavities, such as car dashboards, electrical casings, etc. The advantage of the compression mold is that it can accurately control the size and shape of the product and has strong adaptability to raw materials.

√transfer mold

Transfer molds, also known as transfer molds or injection molds, are another plastic molding method. In the transfer molding process, the plastic raw material is first heated and melted, and then injected into the cavity of the mold through one or more gates. Unlike injection molding, the transfer mold does not apply pressure immediately after the plastic is injected into the cavity, but allows the plastic to flow naturally within the cavity and fill it. The mold is then closed and pressure is applied, further compacting and solidifying the plastic. Transfer molds are suitable for producing high-precision, high-surface-quality plastic products, such as compact discs, precision mechanical parts, etc.

What are the considerations in precision mold design?

Material selection

Material selection is the first step in precision mold design. It is directly related to key properties such as wear resistance, corrosion resistance, heat treatability and thermal conductivity of the mold.

| Propertie | Describe |

| Wear resistance | Mold materials must have high wear resistance to withstand long production cycles. Common choices include high-speed tool steels and carbide, materials that maintain shape and size under conditions of high pressure and friction. |

| Corrosion resistance | Corrosion resistance is an important consideration for molds that process corrosive plastics or are used in humid environments. Stainless steel and nickel-based alloys perform well in this regard. |

| Heat treatability | The selected material should be easily heat treatable to improve its hardness and wear resistance. For example, pre-hardened steel can be quenched and tempered to obtain excellent mechanical properties. |

| Thermal conductivity | Good thermal conductivity helps plastics cool quickly, reducing cycle times. Copper alloys perform particularly well in this regard. |

Cooling channel

The design of cooling channels is another key link in precision mold design, which directly affects the cooling efficiency of the mold and the molding quality of the product.

- Increased productivity: Effective cooling circuit design reduces cooling time, thereby increasing overall throughput.

- Ensure product quality: Uniform cooling can reduce residual stress caused by uneven heat transfer, control warpage of finished products, and maintain the accuracy and stability of the dimensions of molded products.

- Design Points:①Cooling channel size: Commonly used cooling channel diameters include Ø6mm, Ø8mm, Ø10mm, Ø12mm, etc.②The position of the cooling channel: should be adapted to the thickness of the plastic product, focusing on cooling the thicker parts; at the same time, the distance between the cooling channel and the mold wall, ejector pin, sleeve, inlet, oblique pin and other components also needs to be reasonably designed.③Types and configurations of cooling channels: including partition design, jet cooling, heat pipe (pin) and other methods, which can be selected according to specific needs.

Parts ejection mechanism

The design of the parts ejection mechanism is the key to ensuring smooth demoulding of the product.

- Ejection method: Common ejection structures include dome pin, flat top, cylinder, straight top, inclined top, push plate, push block, secondary ejection, etc. The specific choice depends on the shape of the product, its structure and the properties of the plastic used.

- Design Points:

★Ejector pin specifications and position: Ejector pins should be as large as possible and have uniform specifications, and avoid placing them on the top or on an inclined surface; at the same time, pay attention to the ejection stroke and virtual position setting.

★Reset form: Ejection mechanisms such as push blocks should be designed with a reasonable reset form, such as relying on plastic pressure or using a reset rod, etc.

★Special mechanism: For products with inner and outer holes or undercuts that are different from the mold opening direction, which hinder the direct demoulding of plastic parts, special mechanisms such as inclined slider demoulding mechanisms are needed.

What are the common manufacturing methods of precision molds?

※CNC machining

CNC (computer numerical control) machining is a method of high-speed, high-precision cutting using CNC machine tools. This method controls the machine tool through pre-programmed programs to realize automatic processing of molds. CNC machining can produce molds with complex shapes and high precision, and is suitable for various metal and non-metal materials. Its main advantages include high machining accuracy, high production efficiency, high degree of automation and the ability to handle complex-shaped workpieces.

※EDM (electrical discharge machining)

EDM, or electric discharge machining, is a processing method that uses continuously moving thin metal wires (called electrode wires) to perform pulse spark discharge on the workpiece to erode the metal and cut and shape it. EDM is particularly suitable for processing various complex-shaped and precise workpieces, such as punches, concave dies, convex and concave dies of punching dies, etc. Its working principle is to use the high temperature generated by the spark discharge between the electrode and the workpiece to etch away the surface material of the workpiece layer by layer. EDM processing has outstanding advantages such as small machining allowance, high machining precision, short production cycle, and low manufacturing cost. It is an indispensable technology in precision mold manufacturing.

※3D printing

3D printing, also known as additive manufacturing, is a technology that builds three-dimensional objects by stacking materials layer by layer. In precision mold manufacturing, 3D printing technology can achieve rapid prototyping and small batch production. Compared with traditional machining, 3D printing requires fewer steps and can significantly shorten the mold manufacturing cycle. Plastic 3D printing molds are particularly suitable for prototyping and low-volume production. Their costs are much lower than metal molds, and they can respond quickly to customer needs for new products. In addition, metal 3D printing technology is also constantly developing, able to achieve fine details and complex structures, providing more possibilities for mold manufacturing.

What is the role of tight tolerances and quality control?

- Ensure product consistency: By setting and enforcing strict tolerance standards, manufacturers can ensure that each batch of plastic parts produced meets predetermined standards in terms of size, shape, surface finish, etc., thereby achieving a high degree of consistency between products.

- Improve accuracy: Precise tolerance control requires manufacturers to adopt sophisticated equipment and processes during the manufacturing process to reduce production errors. Through sophisticated mold design, high-precision processing equipment and strict production process control, precise plastic parts can be produced that meet or even exceed design requirements.

- Improve customer satisfaction: Customer expectations for products often include high quality, high reliability and good performance. Tight tolerances and quality controls ensure products meet or exceed these expectations, thereby increasing customer satisfaction.

- Reduced production costs: While additional resources may need to be invested initially to establish and implement strict tolerance and quality control systems, this investment will pay significant dividends in the long run. By reducing scrap rates, improving production efficiency and reducing rework costs due to quality issues, companies can reduce overall production costs and improve profitability.

- Enhance market competitiveness: In a highly competitive market environment, companies that can provide high-quality, consistent and precise plastic parts tend to be more competitive. This competitive advantage helps companies win more market share and orders, thereby standing out in the industry.

What are the benefits of precision molds?

1.High precision manufacturing

Precision molds enable highly precise manufacturing and can produce parts or products with high dimensional accuracy and complex shapes. This is very important for some industries that require extremely high precision, such as aerospace, optical instruments, etc. This high precision ensures stable product quality and performance and meets the needs of high-precision applications.

2.Complex shape processing

Precision molds can produce parts or products with various complex shapes, including curves, holes, concave and convex, etc. This enables designers to achieve more innovative and functional designs that meet the needs of different industries.

3.Increase productivity

Precision molds can achieve mass production, greatly improving production efficiency and product quality stability. Through processes such as mold injection molding or die casting, large quantities of the same or similar parts or products can be quickly manufactured. Multiple molds can be used for production at the same time, which greatly reduces the production cycle and improves production efficiency.

4.Save material costs

Precision molds can maximize the use of raw materials and reduce waste and loss. Since the mold can be reused, only one cost is invested in the initial stage, which can save a lot of material costs in the subsequent production process.

5.Improve product quality and consistency

Products made from precision molds have highly consistent sizes and shapes, ensuring stable product quality and performance. This is very important for some industries that have strict product quality requirements, such as medical devices, auto parts, etc. During the production process, the high precision of precision molds can ensure that the processed products meet high-quality requirements and meet the strict standards of customers.

How to choose a plastic mold injector manufacturer?

▲Professional Competency Assessment

Understand the professional ability and experience of service providers in the field of injection molding, including the product types, materials, processes and other they are good at.Investigate the r & d and development capabilities and technological innovation capabilities of service providers, which can be achieved by reviewing their technology patents, r & d results and cases.

▲Production Capacity Investigation

Understand the production scale, equipment configuration, and line automation to ensure they can meet your production needs. Ask the service provider about production cycles and delivery times to ensure they can deliver on time.

▲Quality Control System

Understand the quality management system and certification of service providers, such as ISO 9001, to ensure that they have perfect quality assurance capabilities. Ask the service provider about the quality testing methods and standards, as well as their defective product processing procedures, to ensure that the product quality meets your requirements.

▲Service And Support

Understand the pre-sales and after-sales service support of service providers, including technical support, training, maintenance, etc. Investigate the response speed and problem-solving ability of the service provider to ensure timely and effective support in the cooperation process.

▲Cost And Price

Ask service providers for quotes and cost structure to see if their prices are reasonable. When comparing prices, do not just pursue the lowest price, but to consider the comprehensive cost performance, including product quality, delivery time, service support, etc.

▲Sustainability

Understand the environmental policies and sustainability practices and ensure that their production process complies with environmental regulations.

Investigate the measures and results of service providers in resource conservation, energy utilization and waste treatment.

▲Word Of Mouth And Credibility

To understand the service provider’s reputation and reputation in the industry, we can obtain relevant information by consulting customer reviews, industry reports, media reports, etc. If possible, you can visit the service provider’s production site and management situation, so that you can have a more intuitive understanding of their strength and level.

Why Choose LongSheng For Custom Injection Molding Services?

- Rapid Quotation:Just upload the CAD file, you can quickly understand the manufacturing cost and keep abreast of the order status.

- Quick Molding:Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

- Customized On Demand:Our auto parts manufacturing process is fully customizable according to your specifications, sizes, materials and surface requirements to ensure meeting your unique needs.

- Express Delivery:We are committed to providing, fast manufacturing and delivery to meet your production needs while providing you with greater flexibility to quickly respond quickly to market changes. Longsheng is a partner of your auto parts needs.

conclusion

The manufacturing of precision molds plays a vital role in enhancing the injection molding process. Through various efforts such as optimizing mold design, selecting high-quality materials, fine manufacturing processes, optimizing injection molding processes, strengthening production control, and regular maintenance and upkeep, it can significantly Enhance the injection molding effect in precision mold manufacturing and improve the accuracy and quality of products.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

How does precision mold manufacturing reduce the cost of injection molding?

High-quality mold materials and advanced manufacturing processes are used to improve the wear resistance and corrosion resistance of the mold, extend the service life of the mold, and reduce the frequency and cost of mold replacement. By precisely controlling parameters such as temperature, pressure and speed during the injection molding process, the scrap rate and defective rate are reduced, and material waste and production costs are reduced. You can also improve the production efficiency and capacity of injection molding and reduce the production cost per unit product by optimizing the mold structure and using automated production equipment.

What is the importance of precision mold manufacturing to injection molding?

Precision mold manufacturing is the cornerstone of injection molding quality. The accuracy, design rationality and durability of the mold directly affect the dimensional accuracy, surface quality and production efficiency of injection molded products. Precision molds can ensure higher dimensional stability and surface finish of injection molded parts during the molding process, reduce the rate of defective products, and improve overall production efficiency.

How to improve the accuracy of injection molding through precision mold design?

Optimize the location and size of the sprue to ensure that the plastic melt fills the mold cavity evenly and quickly, reducing defects such as weld lines and shrinkage cavities.

According to the precision requirements of injection molded products, high-precision molds are designed and manufactured to ensure the matching accuracy of each component of the mold. Reasonable design of cooling water channels can also ensure uniform distribution of mold temperature and avoid product warpage and deformation.

Pingback: Precision Injection Mold Making Services - Mekalite

Pingback: Resin Vs. Plastic: Understanding The Core Differences For Better Material Selection