When it comes to choosing CNC machining parts, it’s essential to consider several factors that will impact the quality of the finished product. With so many options in the market, it’s understandable that you might feel overwhelmed at the prospect of making the right choice. However, working with a reputable CNC machining manufacturer can make the process much simpler and stress-free.

In this guide, we’ll explore the criteria you should consider when selecting CNC machining parts for your project. From materials to tolerances, we’ll cover everything you need to know to make an informed decision.

Material Selection

The material selection is the first crucial aspect that you need to consider when choosing CNC machining parts. The material you choose will impact the performance and lifespan of the finished product. The four most commonly used materials in the CNC machining process are aluminum, brass, steel, and plastic.

Aluminum is lightweight, corrosion resistant, and is an excellent conductor of heat and electricity. It’s ideal for products that require a high strength-to-weight ratio.

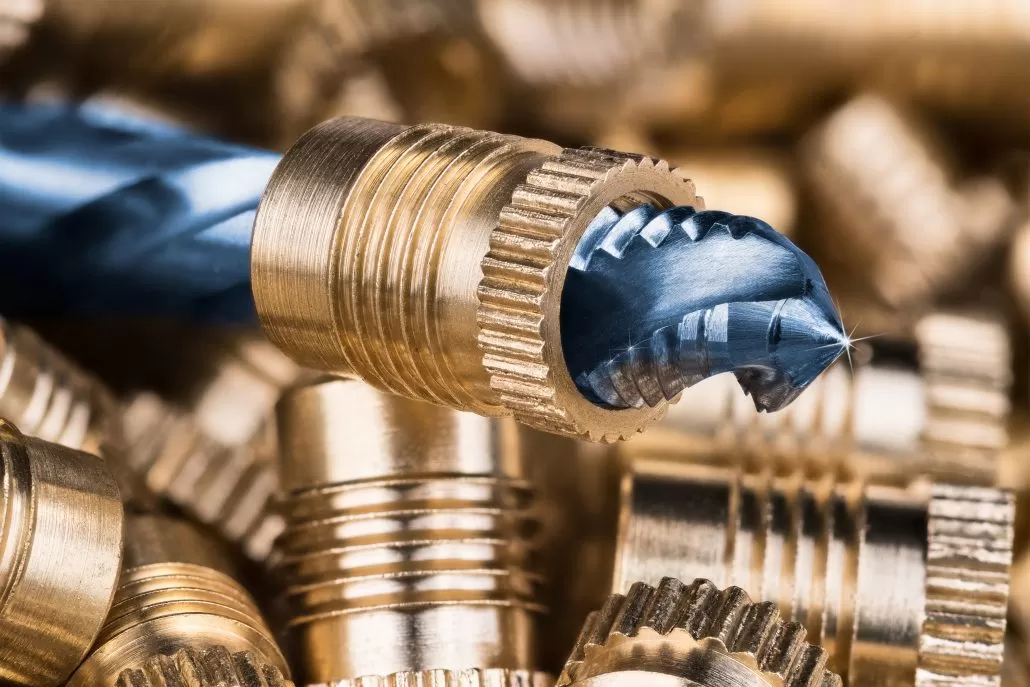

Brass is an alloy of copper and zinc and is known for its excellent machinability and aesthetic appeal. It’s widely used for intricate and detailed parts, such as gears and bearings.

Steel is a robust and durable material that can withstand high-temperature conditions. It’s the go-to material for products that require strength and reliability.

Plastic materials are available in various types, including ABS, Acetal, and Nylon. They’re lightweight, insulating, and have excellent chemical and corrosion resistance properties.

Tight Tolerances

Tolerances refer to the allowable deviation from a particular measurement in the CNC machining process. Tighter tolerances translate to a higher precision finish and are essential to the performance of many industrial and mechanical parts. Choosing a CNC machining manufacturer with a reputation for producing tight tolerance parts can make all the difference in the final product.

Surface Finish

The surface finish of CNC machining parts is another critical aspect that you must consider. The finished product’s surface finish can affect the way it looks and performs. Choosing a reputable online CNC machining manufacturer known for producing high-quality finishes will ensure that your product not only looks great but also functions optimally.

Expertise and Experience

Perhaps the most crucial factor to consider when choosing a CNC machining manufacturer is their expertise and experience in the field. A skilled and experienced team can provide valuable insights and recommendations on materials, design, and manufacturing processes, helping you to optimize your parts for improved performance and cost-efficiency.

Quality Control

Quality control is another critical factor to consider when selecting a CNC machining manufacturer. The manufacturer should have a robust quality control program in place, ensuring that each part produced meets your quality standards and specifications. This involves regular inspection and testing during the manufacturing process, as well as final inspection before delivery.

Design and Engineering

An experienced CNC machining manufacturer should have a team of skilled designers and engineers who can work with you to optimize your part design for improved performance and manufacturability. This can include value engineering to minimize material waste and reduce production costs.

Customer Support

When choosing a CNC machining manufacturer, you should prioritize customer support. A reliable manufacturer will assign you a project manager to explain the manufacturing process, answer your questions, and keep you updated on the project’s progress. They should also be available to address any concerns you may have before, during, and after the project.

Conclusion

Finally, it is essential to choose a reliable and experienced CNC machining manufacturer. A reputable manufacturer will have advanced CNC machines, quality control processes, and experienced engineers and technicians. A good manufacturer will work closely with you to understand your project needs and provide expert advice on the selection of CNC machining parts.

In conclusion, choosing the right CNC machining parts is crucial for the success of your project. By considering the material, tolerance, surface finish, and working closely with a reliable and experienced CNC machining manufacturer, you can ensure the parts meet your project’s requirements. Contact our precision CNC turning machining experts to learn more about our CNC machining services and how we can help you choose the right parts for your project.