In today’s increasingly competitive manufacturing environment, choosing the best CNC machining supplier is crucial to the production efficiency and product quality of enterprises. CNC machining technology occupies a pivotal position in the field of mechanical processing with its high precision and high efficiency. However, there are so many CNC machining suppliers on the market, and how to choose the best supplier has become a problem faced by many companies. This blog will provide a detailed analysis from the following aspects to help you make a wise choice.

What Are CNC Machining Services?

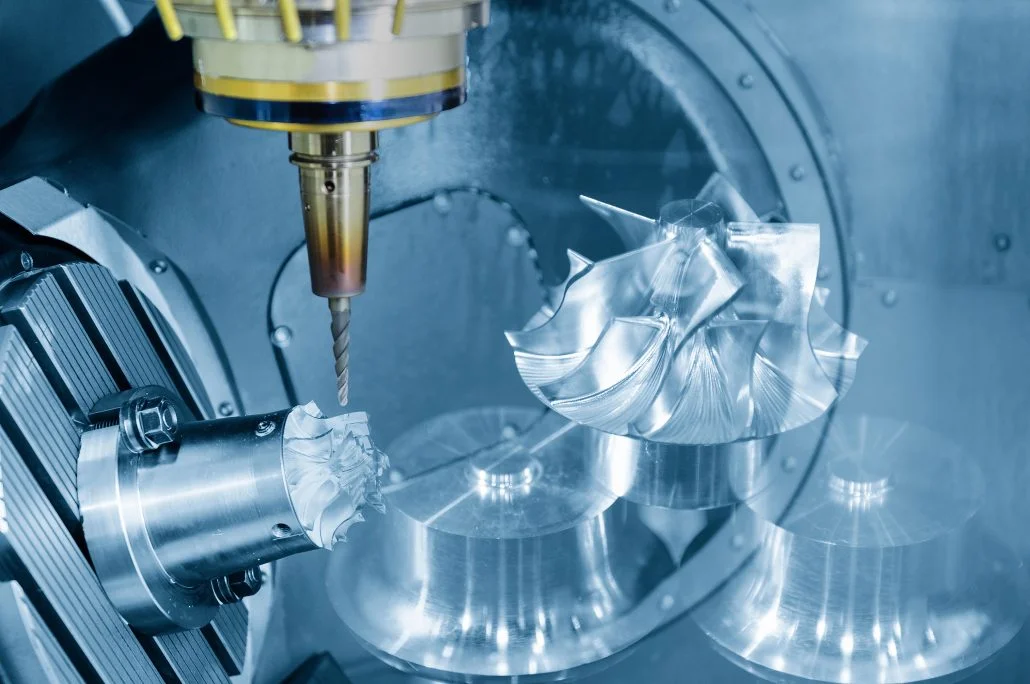

CNC machining services use fast, repeatable and programmable machines to precisely manufacture components. CNC machining is able to perform complex tasks such as cutting, drilling, milling and shaping materials such as metal, wood or plastic, making it a popular choice for a wide range of industry applications including aerospace, automotive, medical devices and consumer products.

How Do CNC Machining Companies Operate?

The way a CNC machining company works usually includes the following key steps:

Receiving customer orders and demand analysis

After receiving the customer’s processing order, the CNC machining company will first have an in-depth understanding of their specific needs, including the required processing materials, product dimensions, accuracy standards, and surface treatment technology.

Programming and design

Technicians will use CAD (computer-aided design) software to design machining drawings according to the specific processing needs of customers. The programmer then uses CAM (Computer Aided Manufacturing) software to translate these designs into G-code or M-code programs that the CNC machine can understand.

Preparation and clamping

Selecting the right material for processing, such as metals, plastics or composites, and then cutting and pre-processing according to the processing needs. Preparation includes the tool and cutting data, the machine structure and the installation tool. The material is fixed on the fixture of the CNC machine to ensure that the material can remain stable during machining.

CNC machining

Input the pre-written program into the control system of the CNC machine tool, and the machine tool will automatically perform cutting, drilling, milling and other processing operations according to the program instructions. During the machining process, the machine tool will monitor the machining status in real time to ensure the accuracy and efficiency of the machining.

Quality inspection

After the machining is completed, we will carry out a series of quality inspections on the workpiece, including but not limited to dimensional determination, surface roughness and shape inspection. If any quality issues are detected, we should immediately rework them or scrap them.

Post-processing and packaging

Necessary post-processing of processed parts, such as deburring, cleaning, surface treatment, etc. The processed parts are packed and ready to be shipped to the customer.

Delivery and customer service

Deliver the processed parts to the customer according to the delivery time required by the customer. To provide customer service, including answering customer queries, handling customer complaints, etc.

What Criteria Define the ‘Best’ CNC Machining Provider?

The criteria for determining the “best” CNC machining supplier can be considered from the following aspects:

1.Ability

Check whether the supplier has advanced CNC machine tools, testing equipment and professional technical personnel. These directly determine whether the supplier can process parts that meet the design requirements and whether it can complete production tasks efficiently and accurately. Assess the supplier’s production scale, optimization of production processes, and ability to handle peak production. Ensure that suppliers can complete orders within the agreed time to avoid delays in delivery.

2.Pricing

Compare quotes from different suppliers and consider cost-effectiveness. Not only should we focus on price, but we should also conduct a comprehensive evaluation based on the supplier’s capabilities, quality, and service levels. Make sure your supplier’s quote is clear and has no hidden fees. This helps companies better control costs during cooperation and avoid budget overruns.

3.Quality

Find out whether the supplier has passed ISO 9001 or other relevant quality management system certification. This helps ensure that suppliers adhere to strict quality standards during production. Examine the quality testing methods and methods of suppliers to ensure that products meet design requirements and industry standards. Understand the supplier’s handling procedures and preventive measures for defective products to ensure that problems are solved in a timely manner to avoid affecting subsequent production.

4.Experience

Evaluate supplier communication effectiveness and responsiveness. Efficient communication helps to solve problems that arise during the cooperation process in a timely manner and ensure the smooth progress of the project. Check whether the supplier provides professional technical support and training services. This helps enterprises obtain better experience and results during cooperation.

5. Services provided to customers

In-depth understanding of the after-sales service policy provided by the supplier, including but not limited to warranty period, repair service and technical support, to ensure timely and effective help when problems are encountered during product use. Collect customer opinions and suggestions on suppliers through questionnaires and establish a database for analysis and improvement. By reviewing other customers’ feedback and comments, you can better understand the supplier’s service level and customer satisfaction, thereby helping companies to have a more comprehensive understanding of the supplier’s strength and reputation.

6. About the turnaround time

Evaluate the supplier’s delivery time to ensure that they can complete the order and successfully deliver the product within the scheduled period. This paper establishes an order response model based on the relationship network between suppliers and customers, analyzes the factors affecting order delays and related countermeasures, and proposes a method to reduce order delays by increasing the number of suppliers. This approach helps companies plan production processes more reasonably, thereby reducing economic losses caused by delivery delays. This paper starts from the relationship between the supplier’s delivery cycle and product quality, production capacity and cost. Evaluate the supplier’s ability to handle order changes or emergencies. Having flexible production capabilities can help companies more effectively adapt to market fluctuations and customers’ changing needs.

How to Avoid Common Pitfalls When Choosing a Provider?

When selecting a provider, you can adopt the following strategies to avoid low-price traps, over-promises and other traps:

| Strategies | Description |

| Market research | Before selecting, you should conduct a full market research, understand the relationship between price level and service quality, compare and analyze quotations, and beware of low-price traps. |

| Evaluation ability | Investigate the provider’s technology, equipment, process and quality control system, and focus on high-precision demand cases and feedback. |

| Contract terms | Before signing the contract, carefully review and clarify the content of the commitment and service, including quality, delivery, breach of contract and other provisions. |

| Third-party inspection | The contract stipulates that a third-party agency accepts product inspection to ensure quality standards and eliminate shoddy work. |

| On-site visits | Visit the supplier’s production site, equipment, employees and management to learn about their culture and concepts. |

| Long-term cooperation | Select suppliers with potential and honesty, build long-term cooperative relationships, strengthen understanding and trust, and promote mutual growth |

Which Companies Lead the CNC Machining Industry?

CNC machining is essential in the field of manufacturing engineering, changing the way parts are manufactured and assembled. Here’s an overview of the top 5 CNC machining parts suppliers:

- Company A: Leader in precision machining, more than 20 years of experience, high-precision parts, in line with industry standards, serving aerospace, automotive, medical industries, ISO 9001:2015 certification.

- Company B: Innovative manufacturing technology, integration of 3D printing, robotics, handling complex projects, rapid prototyping, low-volume production, AS9100 certification, advanced materials expert.

- Company C: One-stop service for all machining needs, including CNC milling, turning, laser cutting, sheet metal fabrication, competitive price, fast turnaround, ISO 13485 certification.

- Company D: Custom CNC Machining Specialist, Years of Experience, Know-how Equipment, Collaborative Design Process, High Quality Materials & Finishes, ITAR Registered.

- Company E: A global giant with operations in 15 countries, extensive facility network, competitive prices, fast delivery, full service, ISO 14001 certification.

When choosing a partner, consider factors such as experience, capabilities, certifications, and price to ensure a successful partnership that will help your business grow.

Why choose LS’s CNC machining services?

LS ensures the quality of your CNC machined parts with ISO 9001:2015, ISO 9001:14001 and IATF16949 certified quality management systems.With advanced 4 and 5-axis CNC machining centers. Our precision CNC machining provide rapid prototyping, small batch machining and high volume production. Unparalleled capacity ensures your CNC parts are shipped on time every time, request an online quote now to have your CNC parts machining in as little as 3 days!

Multi-material processing:We have the ability to process multiple materials. No matter what material CNC parts you need to process, we can provide professional solutions.

Competitive prices:We offer competitive prices and cost-effective solutions to ensure that customers get the greatest advantage in cost control.

Customized services:Provide customized solutions according to customer design requirements and specifications to ensure that CNC parts meet their unique needs.

Fast delivery:We have an efficient production process and flexible production plan, which enables us to deliver customer orders in time and meet urgent project needs.

Conclusion

Choosing the best CNC machining supplier requires comprehensive consideration of multiple factors, including machining capabilities and equipment, quality control system, technical capabilities and experience, delivery capabilities and services, as well as price and cost. By combining actual cases and data analysis, the comprehensive strength of each supplier can be more objectively evaluated, so as to make a wise choice.

In today’s increasingly competitive manufacturing industry, choosing an excellent CNC machining supplier is of great significance to improving the company’s production efficiency, product quality and market competitiveness.

Contact us now to get exclusive CNC machining solutions!

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1.What types of parts can be created using CNC machining?

CNC machining can be used to create a wide variety of cnc parts, from simple components to complex assemblies. cnc parts can be made in a range of sizes, shapes, and configurations, and can be customized to meet specific requirements.

2.Do you accept small batch orders?

Yes,we accept smal batch orders.We have fiexible producion capabiitiesthat can meet the personalized needs of customers,whether it is for smal or large orders.Lear

more about our small batch production capabilities here.

3.Do you have design support capabilities?

Yes, we have a professional design team and CAD/CAM software that can provide design support and advice, including manufacturability evaluation, process recommendations, and optimization of cnc parts. We work closely with customers to ensure that the design of the cnc parts meets the machining requirements.

4.What is your delivery time?

The delivery time varies depending on the complexity, quantity, and machining technology of the cnc parts. We will provide accurate delivery times based on customer order requirements and strive to deliver on time.

5.What is your precision CNC machining ability?

We have advanced CNC machine tools and a technical team that can achieve high-precision, complex shapes and fine details machining, meeting customer precision requirements.

6.Can you provide samples or prototype production?

Yes, we can provide samples or prototype production services according to customer requirements. We can process according to design drawings or samples to verify and confirm the quality and applicability of the cnc parts.Learn more about our rapid prototyping capabilities here

7.Do you have experience in handling complex part machining?

Yes, we have rich experience in machining complex parts, including Multiaxis machining, micro machining and surface machining.

Pingback: CNC Machining in China, USA, or Europe: How to Choose the Optimal Region for Your Project