When it comes to CNC machining, choosing the right parts supplier can make all the difference. Here are some key factors to consider when selecting a supplier for your CNC machining needs:

1. Experience and Expertise

Look for a supplier with a proven track record of providing high-quality CNC machining parts. Check their website and customer reviews to see what other clients have to say about their work. Make sure they have experience in your industry and can provide the expertise you need.

2. Quality Control

Choose a supplier that has a strong commitment to quality control. Look for certifications such as ISO 9001, which demonstrate that the supplier has established and maintains a quality management system. Ask about their inspection processes, and make sure they have a system in place to ensure that every part meets your specifications.

3. Capacity and Capability

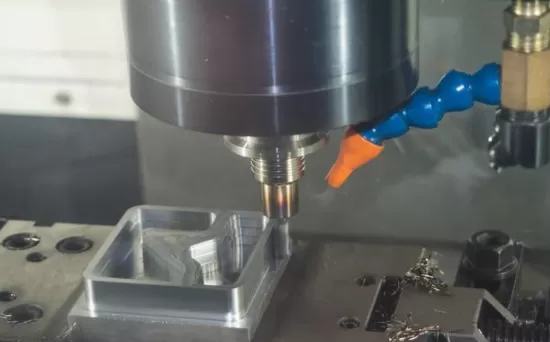

Make sure the supplier has the capacity and capability to handle your order. Ask about their production capabilities, and find out if they have the equipment and personnel to handle your project. Look for a supplier that can handle both small and large production runs, and has experience working with a range of materials.

4. Communication and Collaboration

Choose a supplier that values communication and collaboration. Look for a supplier that is responsive and easy to work with. Make sure they understand your project requirements, and that you are able to communicate your needs clearly. Look for a supplier that is willing to work with you to find the best solution for your project.

5. Price and Value

Finally, consider price and value when selecting a CNC machining parts supplier. Look for a supplier that offers competitive pricing, but don’t sacrifice quality for a lower price. Make sure you are getting the best value for your money, and that the supplier is transparent about their pricing and any additional fees.

By considering these factors, you can choose the right CNC machining parts supplier for your project. Remember to do your research, ask questions, and choose a supplier that is committed to delivering high-quality parts on time and on budget.

6. Location and Shipping

Consider the supplier’s location and shipping options. Choosing a supplier closer to your location can help reduce shipping costs and lead time. Additionally, find out if the supplier offers expedited shipping options in case you need parts quickly.

7. Customization

If you have specific requirements for your parts, it’s important to choose a supplier that can provide customization options. Look for a supplier that can work with you to develop custom parts and has experience in creating unique solutions.

8. Environmental Responsibility

In today’s world, environmental responsibility is becoming increasingly important. Choose a supplier that is committed to reducing their environmental impact. Look for a supplier that uses sustainable materials and recycling programs, and has implemented environmentally friendly practices in their operations.

9. Customer Service

Customer service is an important factor to consider when choosing a CNC machining parts supplier. Look for a supplier that has a dedicated customer service team that can answer your questions and provide assistance when needed. A supplier that values customer satisfaction will be committed to providing excellent service throughout the entire process.

10. Long-Term Relationship

When selecting a CNC machining parts supplier, think about the long-term relationship. Look for a supplier that is willing to work with you to develop a long-term partnership. This can help ensure that you receive high-quality parts consistently and that the supplier is invested in your success.

Choosing the right CNC machining parts supplier is critical to the success of your project. By considering these factors, you can select a supplier that meets your needs and provides high-quality parts on time and on budget. Remember to do your research, ask questions, and choose a supplier that is committed to delivering the best possible service.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,CNC Machining Parts Services,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding, 3D metal and plastic printing and complete traffic key items.

Pingback: Custom CNC Parts Manufacturing | Precision CNC Machining Services Near You

Thank you for your support and attention, we provide you with valuable content every day.

Pingback: Small-Batch CNC Parts Manufacturing | Rapid CNC Machining for Startups

Pingback: How to Choose the Right CNC Machining Supplier? - LONGSHENG

Pingback: How to Choose the Best CNC Machining Provider: A Guide to Evaluating Top Companies