In today’s increasingly competitive environment in the manufacturing industry, choosing the right CNC machining supplier is crucial to an enterprise’s production efficiency and product quality. CNC machining technology occupies a pivotal position in the field of mechanical processing due to its high precision and high efficiency. However, there are so many CNC machining suppliers on the market, how to choose a suitable supplier has become a problem faced by many companies. This blog will provide a detailed analysis of the following aspects to help you make a wise choice.

What Are the Key Factors to Consider When Choosing a CNC Machining Supplier?

In the manufacturing industry, choosing the right CNC machining supplier is a key step to ensure product quality, improve production efficiency, and control costs. Understanding and properly evaluating factors such as a potential supplier’s capabilities, pricing, quality, experience, customer service, and turnaround time are critical to building long-term relationships and driving business success.

1.Ability

Check whether the supplier has advanced CNC machine tools, testing equipment and professional technical personnel. These directly determine whether the supplier can process parts that meet the design requirements and whether it can complete production tasks efficiently and accurately. Assess the supplier’s production scale, optimization of production processes, and ability to handle peak production. Ensure that suppliers can complete orders within the agreed time to avoid delays in delivery.

2.Pricing

Compare quotes from different suppliers and consider cost-effectiveness. Not only should we focus on price, but we should also conduct a comprehensive evaluation based on the supplier’s capabilities, quality, and service levels. Make sure your supplier’s quote is clear and has no hidden fees. This helps companies better control costs during cooperation and avoid budget overruns.

3.Quality

Find out whether the supplier has passed ISO 9001 or other relevant quality management system certification. This helps ensure that suppliers adhere to strict quality standards during production. Examine the quality testing methods and methods of suppliers to ensure that products meet design requirements and industry standards. Understand the supplier’s handling procedures and preventive measures for defective products to ensure that problems are solved in a timely manner to avoid affecting subsequent production.

4.Experience

Evaluate supplier communication effectiveness and responsiveness. Efficient communication helps to solve problems that arise during the cooperation process in a timely manner and ensure the smooth progress of the project. Check whether the supplier provides professional technical support and training services. This helps enterprises obtain better experience and results during cooperation.

5.Customer Service

Understand the supplier’s after-sales service policy, including warranty period, maintenance services and technical support, etc. Ensure that you can receive timely and effective support when you encounter problems during use. Consult feedback and reviews from other customers to understand the supplier’s service level and customer satisfaction. This helps companies gain a more comprehensive understanding of a supplier’s strength and reputation.

6.Turnaround time

Evaluate the supplier’s lead time to ensure that the supplier can complete the order and deliver the product within the agreed time. This helps companies rationally arrange production plans and avoid losses caused by delayed delivery. Examine the supplier’s ability to respond to order changes or emergency orders. Flexible production capabilities help companies better respond to market changes and changes in customer demand.

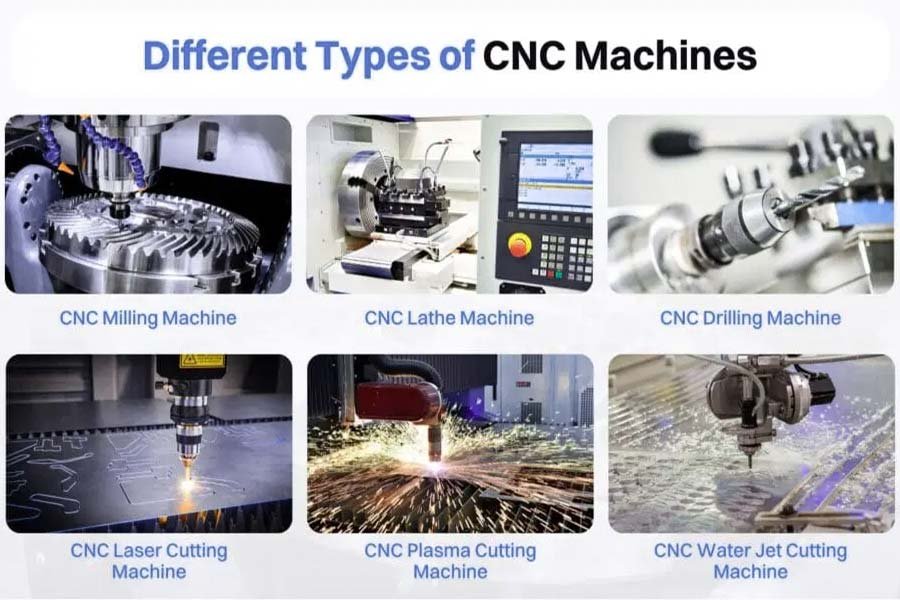

What Are the Types of CNC Services You Need?

When choosing CNC services, it is important to be clear about your specific needs. CNC (Computer Numerical Control) machining services cover a variety of types, each type has its unique application scenarios and advantages. Here’s a detailed breakdown of the types of CNC services you might need:

1.CNC milling

CNC milling is a machining method that uses rotating tools to remove material from a workpiece. It is suitable for creating complex shapes and features such as grooves, pockets, threads and contours. CNC milling is widely used to manufacture parts, molds, prototypes, and custom components.

- Applicable scenarios: Components that require high precision and complex shape processing.

- Advantages: High flexibility and ability to process a variety of materials, including metals, plastics and composites.

2.CNC turning

CNC turning is the process of removing material by rotating a workpiece and using a tool. It is mainly used to produce cylindrical components such as shafts, rods and sleeves. CNC turning is suitable for parts that require high precision and surface finish.

- Applicable scenarios: Manufacturing of cylindrical or rotationally symmetric parts.

- Advantages: efficient, fast, suitable for mass production.

3.CNC grinding

CNC grinding is the process of removing material from the surface of a workpiece through the use of grinding wheels or other abrasive tools. It is often used for precision machining to achieve very high dimensional accuracy and surface finish. CNC grinding is suitable for machining hard materials such as ceramics, glass and certain metal alloys.

- Applicable scenarios: parts processing that require high precision and high surface quality.

- Advantages: Able to achieve micron-level precision control.

4.Customized solutions

In addition to the standard CNC machining services listed above, you may need custom solutions to meet your specific machining needs. This includes designing unique fixtures, tooling and processes to suit the requirements of a specific part or project.

- Applicable scenarios: components with unique or complex processing requirements.

- Advantages: High flexibility, able to meet non-standard processing requirements.

Evaluate whether suppliers offer specialized services such as multi-axis machining or prototyping

When selecting a supplier, in addition to considering the type of CNC machining services they provide, you should also evaluate whether they have the following expertise:

- Multi-axis machining: Multi-axis machining allows multiple machining steps to be completed in a single setup, increasing efficiency and accuracy. Choosing a supplier that can provide multi-axis machining services can simplify the production process and shorten the lead time.

- Prototyping: Prototyping is a critical step in the product development process. Choosing a supplier that can provide high-quality prototyping services can speed up the product verification and testing process and reduce development costs.

Are the materials you need readily available?

CNC machining suppliers are typically capable of processing many types of materials, including but not limited to metals, plastics, and composites.

- Metal: Common metal materials include stainless steel, steel, aluminum, brass, titanium, and copper. These materials are widely used in CNC machining due to their high strength, corrosion resistance, and good mechanical properties.

- Plastic: Plastic materials such as polyoxymethylene (POM), nylon, polyethylene, and acrylic are also commonly used in CNC machining. These materials are lightweight, easy to process, low cost and, in some applications, have excellent resistance to wear and corrosion.

- Composite material: Composite material is a new material composed of two or more materials with different properties through physical or chemical methods. These materials combine the advantages of each component and feature high strength, high stiffness and good corrosion resistance, making them suitable for components with higher performance requirements.

Therefore, it is crucial to ask them if they can readily source materials. Delays in material procurement lead to longer lead times and increased production costs.

What is the lead time for evaluating suppliers?

Time is money, especially in CNC machining. Extended lead times can delay your project, causing delays or even financial losses.Therefore, it is crucial to understand the typical lead times for CNC machining services. It’s also wise to ask about their expedited order policy if you need a faster lead time.

Longsheng is an ISO 9001, ISO14001, IATF 16949 and AS9100D certified company, demonstrating our commitment to quality. These international standards ensure that our quality management system is effective and continuously improved to provide our customers with consistently high quality products. , our typical lead time for CNC machining projects is 1-3 weeks, depending on part complexity and production volume. If there is an urgent need, expedited service can be arranged.

How competitive are their pricing?

Pricing for CNC machining is a complex process that is affected by a variety of factors, including material cost, machining complexity, machine time, and finishing. Price considerations play a vital role in the decision-making process, so when choosing a CNC machining supplier, you need to do a price comparison. Choosing the lowest-cost option can sometimes result in compromises in quality, reliability, or communication. But then again, choosing high-cost options doesn’t guarantee quality and speed. While competitive pricing is crucial, be sure to evaluate the overall value provided by the vendor. To start a CNC machining project, please contact our team and provide your project details, including design files and specifications. We will provide guidance and quotation based on your needs.

What are the qualifications of the supplier and the condition of its equipment?

It is necessary to check whether the CNC processing workshop is equipped with processing equipment and advanced CNC technology that meet the project requirements. This covers key equipment such as CNC lathes, CNC mills, grinders and, in certain cases, coordinate measuring machines used to ensure product quality. The efficiency and effectiveness of CNC machining services largely depend on the tools used. Whether it is a lathe, milling machine or planer, its type and performance are key factors in determining the success of the project. Different types of CNC machines excel at different types of machining tasks.

It is worth mentioning that if a service provider has a variety of high-tech machinery and equipment, this often means that they have the ability to undertake and successfully complete a series of projects. If they can also use cutting-edge technologies such as surface grinding, it is further proof of their commitment to providing comprehensive and high-quality machining services to their customers.

What Is Their Reputation in the Industry?

Evaluating the reputation of a CNC machining supplier requires comprehensive consideration of multiple aspects, including online reviews, industry status, on-site visits, sample evaluations, recommended cases, financial stability, and after-sales service. Through these steps, you can gain a comprehensive understanding of a supplier’s strength and reputation, allowing you to make an informed choice.

A good reputation and positive reviews demonstrate a supplier’s commitment to quality and customer satisfaction. Longsheng has built a loyal customer base by providing exceptional CNC machining services and ensuring every project meets strict standards. Our customers span industries from machine manufacturing to automation, and they consistently praise our precision, reliability and dedication. A reputation for excellence is a reliable indicator of the value of a CNC machining supplier, making Longsheng the first choice for those looking for reliable results.

What are the supplier’s quality assurance procedures?

Reliable CNC machine shops follow strict quality control procedures to ensure high-quality parts are produced. They use equipment such as pin gauges, coordinate measuring machines and modern software to ensure accuracy and adhere to original dimensional requirements. In addition to performance details, you must also be provided with quality control documentation available so that you can truly understand the company you are considering for custom CNC machining or precision CNC machining.

Why Choose Longsheng Customized CNC Machining Services?

By choosing our precision CNC machining manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent CNC machining solutions for your project.

- Quick quote:Simply upload CAD files to quickly understand manufacturing costs and keep track of order status.

- Rapid prototyping:Longsheng has extensive experience in prototyping, ensuring your components are completed with high quality in the later stages of the design and manufacturing process.

- ISO certification:Longsheng is an ISO 9001 certified manufacturing company, which means we use internationally recognized best practices to develop your products and ensure they meet standards, regardless of the complexity of the design.

- Customized on demand:Our CNC machining manufacturing process is fully customizable to your specifications, dimensions, materials and surface requirements to ensure your unique needs are met.

- Express delivery:We are committed to supplying, manufacturing and delivering quickly to meet your production needs while giving you greater flexibility to respond quickly to market changes. Longsheng is your partner for your CNC machining parts needs.

Conclusion

When companies select CNC machining suppliers, they should comprehensively consider key factors such as capabilities, pricing, quality, experience, customer service and turnaround time. By comprehensively assessing the strength and reputation of potential suppliers, companies can establish long-term and stable cooperative relationships, ensure the selection of high-quality suppliers that meet the requirements, and provide strong support for the company’s production and development.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Pingback: What Factors Affect CNC Machining Prices?

Pingback: How to Compare CNC Machining Prices?

Pingback: How to Choose the Best CNC Machining Provider: A Guide to Evaluating Top Companies