CNC (computer numerical control) machining plays a vital role in modern manufacturing and is popular for its high precision and flexibility. However, CNC machining prices offered by different manufacturers often vary significantly, making choosing the right machining service challenging. This article will explore how to compare CNC machining prices to help you make an informed decision.

How to Estimate CNC Machining Costs?

The following key factors need to be considered when estimating CNC machining costs:

- Material cost: first determine the type and quantity of the required machining materials, and then query the current market price, so as to calculate the material cost.

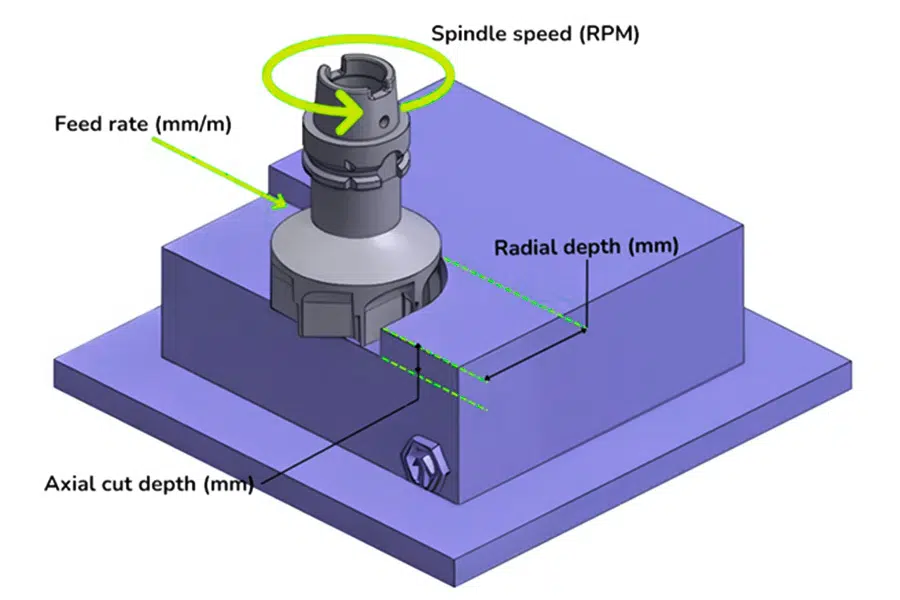

- Processing time and rate: to evaluate the machining complexity of the parts and to estimate the required processing time. At the same time, according to the performance of the machining equipment, depreciation rate and labor cost and other factors, set a reasonable machining rate (machining cost per unit of time). The machining time cost is obtained by multiplying the processing time by the processing rate.

- Depreciation and maintenance of equipment: considering the purchase cost and service life of CNC machine tools, calculate the depreciation cost of equipment. At the same time, estimate the daily maintenance costs of the equipment, such as the cost of tool replacement, lubricant and other consumables.

- Labor cost: based on the number of operators, programmers and technical support personnel required, working hours and local labor rates.

- Other additional costs: it may include packaging design, transportation costs, taxes, management fees, etc. These costs are specific and need to be considered in actual estimates.

What are the steps of comparing numerical control machining price?

- Clear requirements: First of all, you need to identify your machining requirements, including the materials, size, complexity, accuracy requirements, and quantity of the parts. This will help you get your quotes more accurately.

- Collect quotation: provide your drawings or machining requirements to multiple CNC machining plants, and request quotations. Ensure that all manufacturers quote based on the same requirements for a fair comparison.

- Analysis of the composition of the quotation: after receiving the quotation, carefully analyze the composition of the quotation. Understand the details of the cost, such as material, machining , surface treatment, etc. This helps you identify potential additional costs or hidden costs.

- Consider quality and service: Don’t ignore the importance of quality and service when comparing prices. A manufacturer with strong technical strength, advanced equipment and good service, although it may offer slightly higher prices, but usually can provide more reliable products and better after-sales support.

- Reference to the market conditions: to understand the local CNC machining market conditions, including the average hourly rate, common material prices, etc. This helps you to justify the offer.

Longsheng: Parts being processed

CNC machining cylinder block

The CNC-machined cylinder block by Ls exemplifies precision manufacturing tailored to meet the needs of industries such as aerospace, automotiveindustrial equipment, renewable energy, and robotics, Designed with advanced 5-axis CNc machining, this component ofers exceptional durablilityaccuracy,and reliability for complex high-performance systems.

Key Features of the CNC-Machined Cylinder Block

- Exceptional Dimensional Precision:Produced with 5-axis CNC machining, the cylinder block delivers tioht tolerances, ensuring precise integration into high-performance systems.

- High-Strength Materials:Constructed using aerospace-grade aluminum, stainless steel, or titanium, this block offers superior strength and corrosion resistance.

- Lightweight and Durable Design:This cylinder block combines lightweight properties with exceptional durability, ensuring performance in demanding environments.

- Advanced Surface Finishing:Finished with advanced grinding and polishing technigques, the cylinder block is burr-free and smooth, enhancing its functionality and visual appeal.

- Fully customizable Specifications:The cylinder block can be customized to meet project:specific needs, including design modifications,additional dried holes, and specific surfacetreatments.

Longsheng’s Advanced Manufacturing Process

- Material Selection:We use high-auality materials such as aerospace aluminum, stainless steel, and titanium, ensuring strenath and long-term performance.

- CNC Machining Precision:Our CNC miling and CNC turning capabilities deliver exceptional precision for intricate designs and tight tolerances.

- Surface Treatments:Optional treatments,including anodizing, powder coating, and electropolishing, enhance the cylinder block’s resistance to wear and environmental factors.

- Rigorous Quality Control:Every cylinder block undergoes stringent quality inspections to meet $0-certified standards for accuracy, durability, and reliability.

How to Compare CNC Machining Quotes from Different Suppliers?

In the manufacturing industry, choosing a suitable CNC machining supplier is particularly critical. In many cases, it is difficult to choose a good supplier, because it not only considers the price of machine tools, technical performance and other factors, but also weighs its quality level and whether the after-sales service is perfect. But, in the face of numerous suppliers and complex offers, how to compare and make smart choices has become a challenge for many buyers. Here we will introduce some commonly used methods to improve the procurement efficiency and reduce unnecessary expenses. Longsheng will assist you to easily compare the CNC machining quotation provided by different suppliers.

- To ensure transparency in the nature of the quotation, when the CNC machining quotation is required, the supplier must provide details including materials, machine running time, post-processing, and additional service costs.

- When evaluating the total cost, we will take into account the overall cost of producing the same parts in the process of comparing the quotation, which includes the potential cost, delivery time and quality control, in order to view the problem from a more comprehensive perspective.

- When choosing suppliers, in addition to the price factor, we also need to pay great attention to the quality and reputation of suppliers, in order to avoid the inferior materials and rough machining process caused by the low price. Before selecting selection, study historical background, customer evaluation and reputation to ensure competitive quality and price.

Case analysis:

Suppose you need to machine 50 aluminum alloy parts, the material is 6061, the size is 100mm x 50mm x 25mm, and the surface treatment is anodized.

- Supplier A’s quotation: Material cost: 2,000 yuan, machining time: 10 hours, surface treatment: 1,000 yuan, total price: 4,000 yuan.

- Supplier B’s quotation: Material cost: 2,500 yuan, machining time: 8 hours, surface treatment: 1,200 yuan, total price: 4,700 yuan.

- Quotation from Supplier C: Material cost: 1,800 yuan, machining time: 12 hours, surface treatment: 800 yuan, total price: 3,600 yuan.

Data analysis:

- Total price: Supplier C has the lowest price, which is 3,600 yuan.

- Material cost: Supplier C has the lowest material cost, which is 1,800 yuan.

- machining time: Supplier B has the shortest machining time, which is 8 hours.

- Surface treatment: Supplier C has the lowest surface treatment cost, which is 800 yuan.

Conclusion:

Although Supplier C has the lowest total price, its machining time is longer. If you do not have high requirements on delivery time, you can choose supplier C. If you have higher requirements on delivery time, you can choose supplier B, but its total price is higher. Supplier A’s quotation is between the two, you can choose according to your needs.

How Do CNC Machining Materials Influence the Price?

The factors that affect the price of CNC machining materials mainly include the cost of the material itself, the ease of processing, the tool loss rate, and the required surface treatment. Different materials can have significant differences in machining costs due to their unique physical and chemical properties.

Case:

As a lightweight and relatively cheap material, aluminum alloy has a relatively simple machining process and is very suitable for mass production. For example, the raw material cost of an aluminum alloy part may be only 50 yuan, and because of its easy machining characteristics, the processing cost is relatively low.

In comparison, the price of stainless steel is much higher, and its machining difficulty is also increased accordingly, which results in faster tool wear during the machining process. If stainless steel is used to process the same parts, the material cost may rise to 100 yuan, and due to the extension of machining time, the overall cost may be twice that of aluminum alloy parts.

Titanium alloy is a completely different material that is expensive and extremely difficult to process. In order to machine titanium alloy parts, special tools are usually required and the machining time will increase significantly. Therefore, the processing cost of titanium alloy parts may be 3 to 5 times that of aluminum alloy parts.

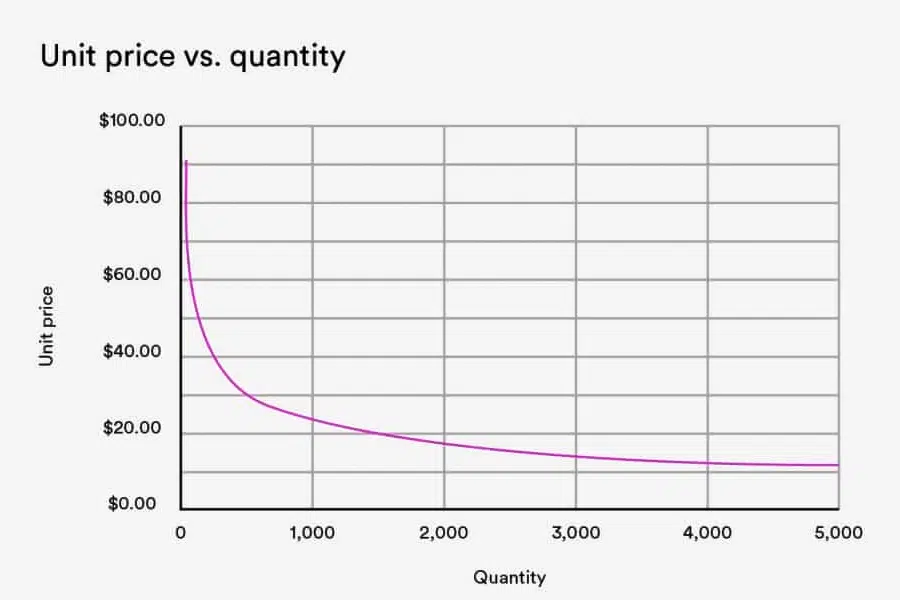

How Does Quantity Impact CNC Machining Pricing?

The impact of quantity on CNC machining pricing is mainly reflected in the apportionment of unit costs, improvements in production efficiency and possible batch discounts. High-volume production can significantly reduce unit costs.

Case:

Small batch production (10 pieces): Assume that the programming and equipment setup cost is 500 yuan, the single-piece machining time is 1 hour, and the hourly machine cost is 100 yuan. The cost of a single piece is: (500 + 10×100) / 10 = 150 yuan.

Mass production (100 pieces): The same programming and setup cost is 500 yuan, and the single-piece processing time is optimized to 0.8 hours. The cost of a single piece is: (500 + 100×80) / 100 = 85 yuan.

Volume discounts: Suppliers may offer a 5% discount on orders of 100 or more, further reducing unit costs.

Data Comparison: Longsheng vs. Competitors

In this section, we will analyze in detail the comparison of CNC machining prices between Longsheng and three competitors (Suppliers A, B and C). By looking at this data, we can see that Longsheng outperforms its competitors in cost control, delivery time, and customer service.

Price is one of the most critical factors for customers when machining parts. Below is a comparison of Longsheng online quote and the competitors’ prices:

| Supplier | Unit Price (USD) | Total for 20 Parts (USD) | Unit Price for 5000 Parts (USD) |

|---|---|---|---|

| LS | 100 | 2000 | 20 |

| Supplier A | 200 | 5260 | 53 |

| Supplier B | 178 | 3560 | 36 |

| Supplier C | 137 | 2740 | 27 |

- Longsheng ’s Unit Price Advantage: For 20 sample parts, Longsheng offers a unit price of100 USD, significantly lower than Supplier A’s263 USD, and even more cost-effective than Supplier B’s178 USDand Supplier C’s137 USD.

- Cost Savings for Bulk Production: When producing 5000 parts, Longsheng ‘s unit price drops to20 USD, while other suppliers range from27 USD to 53 USD, allowing customers to save a significant amount on large-scale production.

Why choose Longsheng for CNC machining manufacturer?

By choosing Longsheng,customers can enjoy core benefits:

- Lower production coststhrough competitive pricing.

- Faster market responsewith quick lead times.

- Higher product qualitywith precision machining.

- Comprehensive customer supportthroughout the project lifecycle.

Choose LS for a partner that delivers cost-effective, high-quality solutions that drive long-term success.

How to Start Working with Longsheng?

Now that you know the advantages of Longsheng, we invite you to contact us and start collaborating with us.

- Request a Quote:Get a customized online quote based on your specific needs.

- Book a Consultation: Schedule a free consultation with our engineers.

- Contact Us: Our team is ready to assist you with all your needs.

Conclusion

Comparing CNC machining prices is a comprehensive consideration process involving multiple factors. By clarifying needs, collecting quotations, analyzing quotation composition, considering quality and service, referring to market conditions, and communicating and confirming, you can more accurately evaluate quotations from different manufacturers and make informed decisions. Remember, price is not the only criterion, quality, service and technical strength are equally important.

Contact us now to get exclusive customized CNC machining solutions!

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Pingback: What Are the Hidden Costs in CNC Machining?

Pingback: How to Reduce CNC Machining Expenses?

Pingback: What Information Is Needed for a CNC Machining Quote?

Pingback: What to Expect in a CNC Machining Quote?

Pingback: Best Online CNC Quote Services Platform – On Demand Manufacturing Map

Hi, i think that i noticed you visited my weblog thus i got here to “go back the choose”.I’m attempting to in finding things to improve my site!I assume its good enough to use a few of your ideas!!

Thank you for your attention, please subscribe to us and share valuable information with your friends in need, have any needs, please send us an inquiry.