As a key component of the drill fixture, the design of the drill bushing is directly related to processing accuracy, efficiency and safety. This blog will detail how to design a custom drill bushing for specific needs, including explaining the importance of custom drill bushings and their impact on drilling efficiency, discussing the materials commonly used for custom drill bushings (e.g., high-speed steel, carbide) and the manufacturing involved Process, discusses factors to consider when designing custom drill bushings, including dimensions, tolerances and compatibility, and highlights the advantages of using custom drill bushings, such as improved performance, reduced wear and cost savings, etc., to help everyone in the process of designing custom drill bushings Don’t feel confused, let’s start learning today!

What is Drill Bushings?

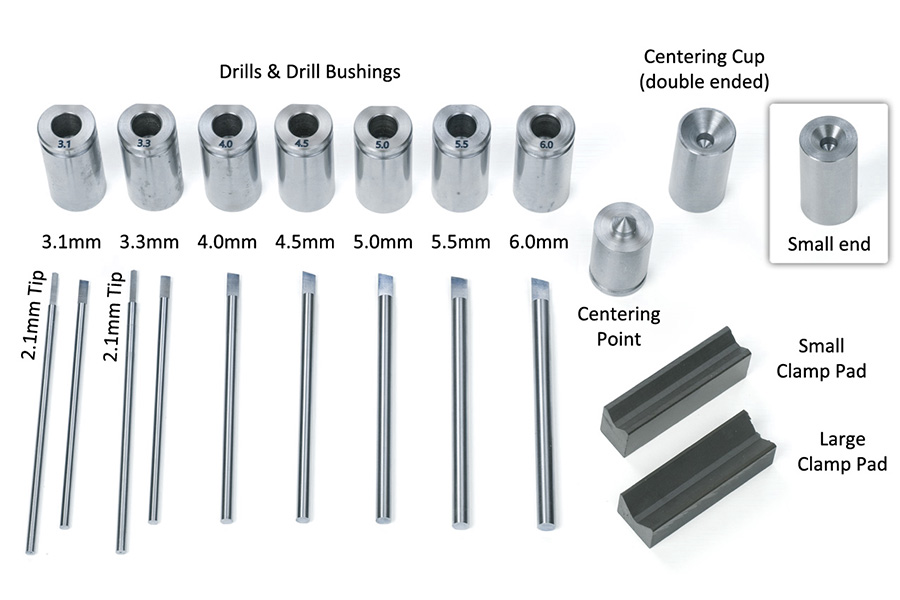

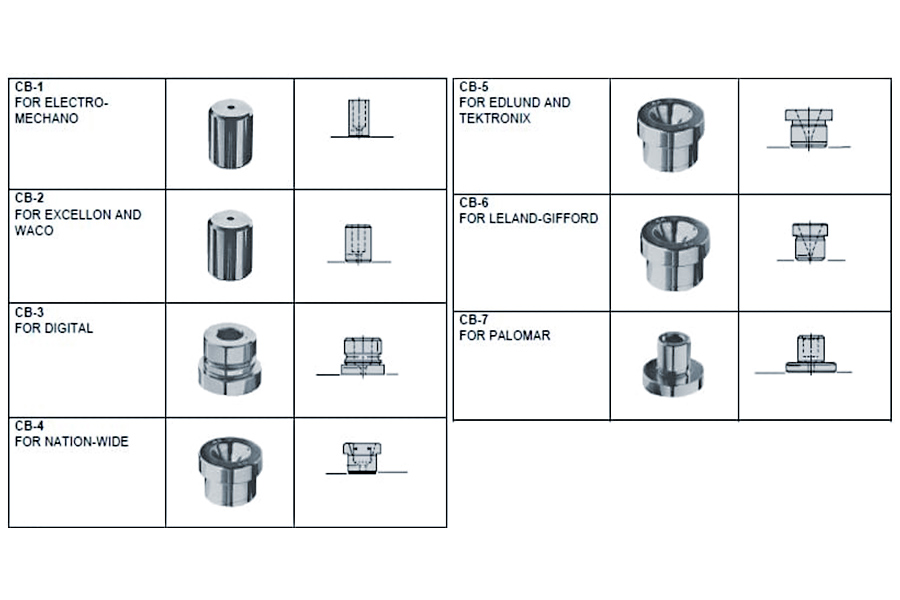

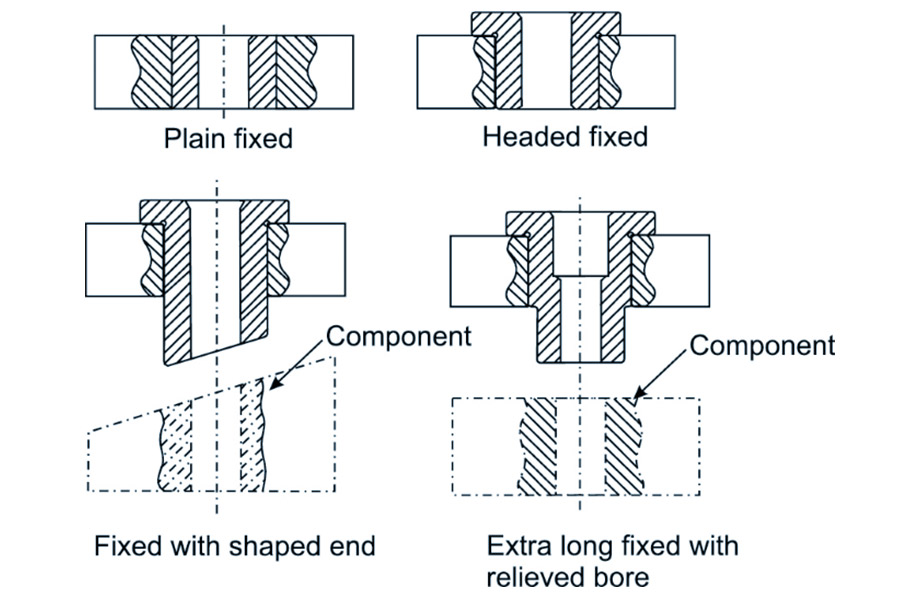

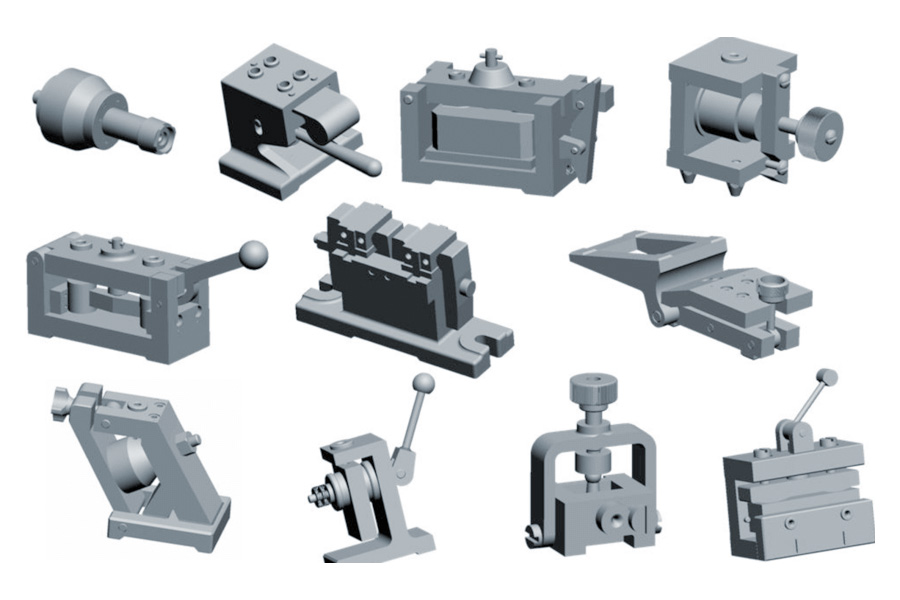

Drill bushings (also known as jig bushings) are installed in drill fixtures and are used to guide, position and support drill bits, reamers, countersinks and counterbores to ensure accurate and repeatable hole placement during metalworking tasks. Drill bushings prevent cutting tools from deflecting or bending as they enter the workpiece, maximizing chip clearance and minimizing the risk of damaging the workpiece or fixture. Press-fit bushings are permanently pressed into the clamp. Slip-on replaceable bushings can be replaced between jobs, making them ideal for applications where the bushings are expected to wear out before the job is completed. Headless bushings can be fitted tightly together. Headed bushings have an overhang or head that prevents them from being pushed through the clamp, making them ideal for applications where load or vibration may cause the bushing to move. Bushing bushings are installed in a clamp to hold replaceable bushings in place and facilitate replacement of worn or damaged bushings.

Common drill bushings types and their characteristics

Drill bushings can be divided into the following types according to their types:

1.Fixed drill bushing

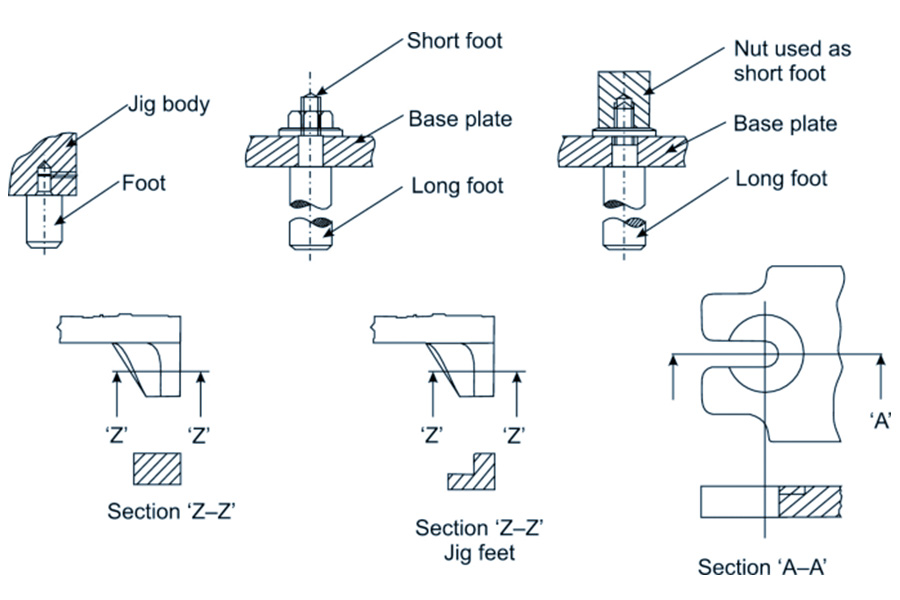

The fixed drill bushing is directly pressed into the hole of the drill template or fixture, and an interference fit is used between its outer circle and the hole of the drill template or fixture to ensure that the drill sleeve will not loosen or move during use. It is suitable for a single drilling process in small and medium-sized batch production, especially when the drilling accuracy is required and the production batch is not large.

Features

- The structure is simple and easy to install.

- The drilling accuracy is high because the position of the drill bushing is fixed and deviation is not easy to occur.

- However, it is not easy to replace after wear and tear, and the drill template or fixture needs to be replaced as a whole, which is costly.

2.Replaceable drill bushing

The replaceable drill bushing is installed in the bushing, and the bushing is press-fitted on the drill template. The drill bushing and the bushing and the bushing and the drill template are fixed with appropriate matching methods. At the same time, the drill bushing is further compressed by screws and other fasteners to prevent the drill bushing from rotating or withdrawing during the processing.

Features

- Easy to replace after wear, simply loosen the fasteners to remove and replace with new drill bushings.

- It is suitable for a single drilling process in mass production, which can improve production efficiency and reduce costs.

- However, compared with fixed drill bushings, its structure is more complex and requires more operating steps during installation and replacement.

3.Quick change drill bushing

The quick-change drill bushing is designed to meet the needs of drilling, expanding, reaming and other processing methods in sequence in the same process. It can quickly replace drill bushings of different hole diameters without changing the drill template or fixture.

Features

- Replacement is quick and easy, just turn the chamfered edge of the drill bushing to the screw and you can easily take it out and replace it with a new one.

- It is suitable for occasions that require multiple processing methods in the same process, and can significantly improve production efficiency and flexibility.

- The structure is relatively complex, but rapid replacement and efficient processing can be achieved through reasonable design and optimization.

4.Special drill bushing

When the workpiece shape or processing conditions limit the use of standard drill bushings, special drill bushings need to be designed. The design of special drill bushings needs to fully consider the convenience of loading and unloading workpieces, the convenience of chip removal and cooling tools, as well as the error prevention device to prevent the workpieces from being installed in the wrong position.

Material Selection for Custom Drill Bushings

- High Speed Steel (HSS): This is a common drill bushing material widely used in various drilling operations due to its high hardness and good cutting ability. It is suitable for hand drilling and some equipment with low automation.

- Carbide (also called tungsten steel): Compared with high-speed steel, carbide has higher hardness and wear resistance, and is more suitable for equipment with high automation and high precision requirements. Its stability and precision are higher, and it is the first choice material for customized high-precision drill bushings.

- Ceramics: Ceramic materials have extremely high hardness and wear resistance, even exceeding that of carbide. Its hardness can be as high as 1600HRC, which is the first choice for processing super-hard materials and customized drill bushings.

- Alloy steel: Alloy steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloying elements to ordinary carbon steel. The properties of alloy steel vary depending on the added elements. Alloy steel has high strength and toughness. High-quality materials for custom-made high-strength drill bushings.

What are the key points in drill bushings structural design?

The structural design of the drill bushing needs to be based on the processing requirements and workpiece characteristics. Here are some key design points:

Guide length

The guide length of the drill sleeve has a great influence on the guide function of the tool. The ratio of guide length H to its hole diameter (H/d) should be reasonably selected based on the processing accuracy and hole size. Generally speaking, when the processing accuracy requirements are high or the hole diameter is small, the H/d value should be larger; when the processing hole diameter is larger or the distance tolerance between the two holes is small, the H/d value can be appropriately reduced.

Chip clearance

The chip clearance h refers to the space between the bottom of the drill bushing and the surface of the workpiece. Properly setting the chip removal clearance can ensure smooth discharge of chips and avoid damage to the processing surface and breakage of the drill bit. Generally, when processing cast iron parts, h=(0.3-0.7)d; when processing steel parts, h=(0.7-1.5)d, d is the diameter of the drill bit.

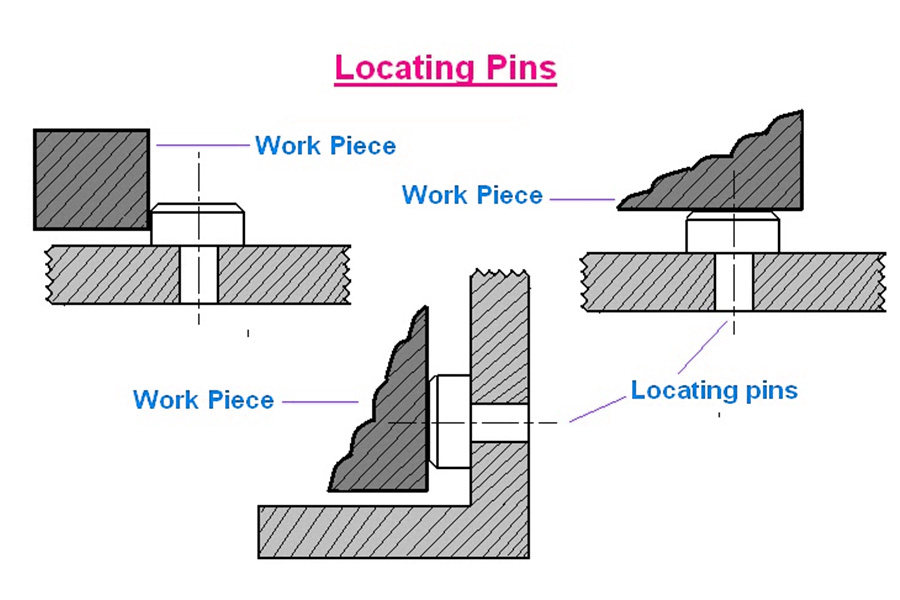

Anti-accidental device

In order to prevent the workpiece from being installed in the wrong position, anti-error devices should be installed on the drilling tool, such as obstacle pins or other limiting mechanisms. These devices should be reasonably designed and easy to operate to ensure that the workpiece can be accurately installed in the designated position.

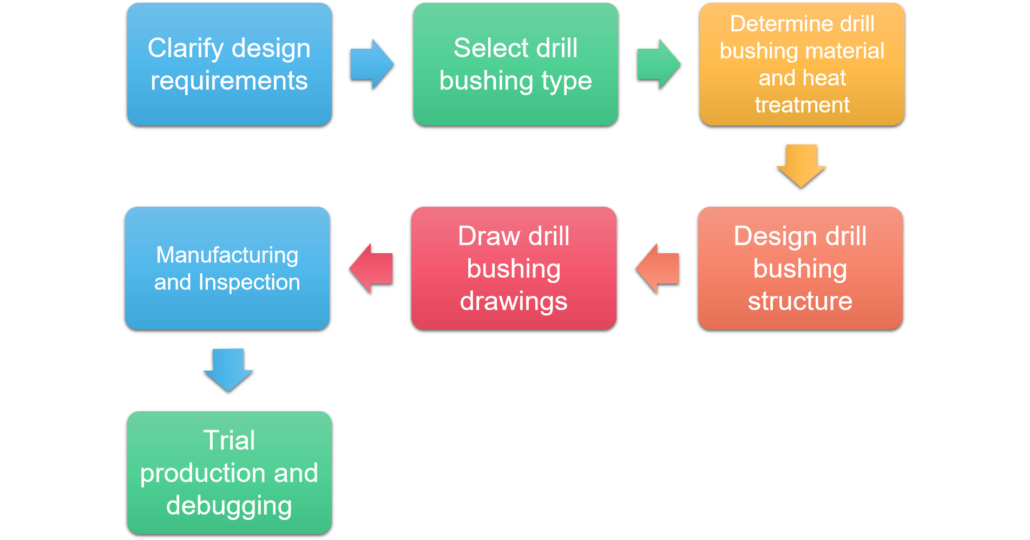

What are the steps in the processing process of custom drill bushings?

Material selection

Choose appropriate materials based on the use environment and functional requirements of the drill bushing. Commonly used materials include metals (such as copper, aluminum, 45# steel, stainless steel, etc.) and non-metals (such as PE, PP, PVC, ABS, PMMA, POM, PA, etc.). The specific choice of material needs to be determined based on customer requirements and product performance.

Blank preparation

Select the appropriate blank according to the structure and size requirements of the drill bushing. For bushings with smaller bore diameters, hot-rolled or cold-drawn bars are generally selected; for drill bushings with complex structures or larger sizes, castings or forgings may be required. According to the design drawing of the drill bushing, determine the outer diameter, length and other dimensions of the blank, and reserve sufficient processing allowance.

Processing process

①Choose an appropriate positioning reference to ensure processing accuracy. For drill bushings, the inner hole or outer circle is usually used as the positioning reference.

② Develop a detailed process route in accordance with the principle of roughing first and then fineness, surface first and then drilling. It generally includes steps such as blanking, rough machining, semi-finishing, finishing, and inspection.③Choose appropriate processing equipment and process equipment, such as lathes, milling machines, drilling machines, grinders, etc., as well as corresponding fixtures, cutting tools, etc.

Inspection and warehousing

Strict inspection is carried out on the processed drill bushings, including dimensional inspection, geometric tolerance inspection, surface roughness inspection, etc., to ensure that the quality of the drill bushings meets the requirements. After passing the inspection, the drill bushing will be cleaned, rust-proofed, and properly stored or stored in storage.

How to Design Custom Drill Bushings?

What factors need to be considered when designing custom drill bushings?

- Drill size and accuracy: Determine the diameter, depth, and tolerance range of the required drill hole. Drill bushings should be designed to closely match drill bit size to reduce deflection and improve drilling accuracy. Consider whether you need to adjust the drill diameter or accommodate drill bits of different sizes. It may be necessary to design an adjustable or replaceable drill bushing structure.

- Material selection: Choose appropriate materials according to the application scenario, such as carbide, high-speed steel, stainless steel or specific engineering plastics. The material needs to be hard and wear-resistant enough to withstand the friction and heat of the drilling process. Consider material cost, processability, corrosion resistance and thermal stability.

- Structural strength and stability: The design should ensure that the drill sleeve has a stable structure and can withstand the axial force and torque during drilling to prevent deformation or fracture. Consider mounting methods and securing mechanisms to ensure that the drill sleeve does not loosen or shift during operation.

- Cooling and Lubrication: Consider how to effectively cool and lubricate the drill bit when designing to reduce friction, extend tool life and improve machining efficiency. It may be necessary to design cooling channels or integrate a lubrication system.

- Processing technology: According to the selected materials and design requirements, select the appropriate processing technology, such as precision casting, machining, heat treatment, etc. Considering processing cost, cycle time and accuracy requirements, optimize the design solution to reduce costs and improve production efficiency.

- Usage environment: Analyze the usage environment of the drill bushing, including factors such as temperature, humidity, corrosive gases, etc. to ensure that the design meets environmental requirements. Consider whether special coatings or treatments are needed to improve the drill bushing’s corrosion or wear resistance.

- Maintenance and care: When designing, the ease of maintenance and upkeep of the drill sleeve should be considered, such as ease of disassembly, cleaning and replacement of worn parts. Provide necessary maintenance manuals and maintenance instructions to extend the service life of drill bushings and reduce maintenance costs.

Cost-Effectiveness Considerations When Designing Custom Drill Bushings

| Cost-Effectiveness | Describe |

| Material cost | The cost of different materials varies significantly. For example, although carbide and high-speed steel have superior performance, their costs are relatively high; stainless steel and some engineering plastics may be more economical in cost. When choosing a material, weigh its performance, durability and cost. |

| Processing cost | Different processing techniques have different impacts on costs. For example, the cost difference between precision casting and machining is large, and the appropriate process needs to be selected according to product requirements. At the same time, complex processing techniques may increase labor and equipment costs. |

| Design cost | Design complexity directly affects the manufacturing cost of the product. Overly complex designs may increase processing difficulty and cost. Therefore, the structure should be simplified as much as possible during the design process to reduce design complexity. |

| Maintenance costs | The ease of maintenance of the product should be considered when designing so that repairs and parts can be easily replaced during use. This reduces maintenance costs and increases product lifespan. |

| Long-term benefits | High-quality product performance can improve customer satisfaction and increase product sales, thereby bringing long-term economic benefits. Therefore, during the design process, attention should be paid to improving product performance and meeting customer needs. |

What are the advantages of custom drill Bushings?

★Improve processing accuracy

The main function of the drill bushing is to determine the axis position of fixed-size tools such as drill bits, reamers, reamers, etc., thereby ensuring the accuracy of machined holes. Custom drill bushings can be precisely designed based on specific machining needs to achieve higher positioning accuracy.

★Ensure processing quality

The drill bushing can prevent the drill bit from eroding the hole wall and ensure the smoothness of the drilling surface. This is particularly important for machined parts that require high-precision surface quality. Customized drill bushings can also improve the rigidity of the tool during processing and prevent vibration during processing, thereby further ensuring processing quality.

★Improve production efficiency

In some cases, customized drill bushings can be designed as quick-change types to facilitate rapid replacement of drill bushings with different hole diameters in different processes, thereby improving production efficiency. Using custom drill bushings can avoid repeated measurement and correction work caused by drill bit deflection, saving time and labor costs.

★Strong adaptability

Machined drill bushings are suitable for drilling various materials, such as steel, aluminum, copper, cast iron, etc., and have a wide range of applications. Customized drill sleeves can be personalized according to specific processing materials and process requirements to meet the needs of different processing scenarios. When the structural shape of the workpiece is not suitable for standard drill bushings, special drill bushings can be customized to suit the workpiece shape and processing requirements. .

★Economical and cost-effectiveness

Although the initial cost of custom drill bushings may be higher, due to their high precision, high quality and high efficiency, they can significantly reduce processing costs and improve product quality in the long run. Customized drill bushings ensure consistent processing accuracy and quality, thereby reducing material waste and rework costs caused by substandard processing.

Summary

Drill bushings design is a comprehensive process that requires consideration of multiple factors. Through reasonable design and manufacturing, it can be ensured that the drill sleeve meets the processing needs and improves processing accuracy and efficiency. At the same time, with the continuous development of processing technology, the design of drill bushings will continue to be innovated and improved.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

How to determine the type of drill bushings?

To determine the type of drill bushings, you must first analyze the material, shape, size and processing requirements of the workpiece. Fixed drill bushings are suitable for small batch production or simple drilling; replaceable drill bushings are suitable for occasions that require frequent tool changes; quick-change drill bushings are suitable for occasions where the processing process contains multiple steps; special drill bushings are suitable for Workpiece design for special shapes or processing conditions.

How to design the chip clearance?

The chip clearance h refers to the space between the bottom of the drill bushing and the surface of the workpiece. The smooth discharge of chips should be considered during design to avoid damaging the machined surface or breaking the drill bit. For different materials and processing requirements, the selection of h value is also different. For example, for iron castings, the h value can be (0.3-0.7)d; for steel parts, the h value can be (0.7-1.5)d.

How to choose the material of drill bushings?

The selection of drill bushings material should be determined based on the material and processing requirements of the workpiece to be processed. Generally speaking, the drill bushings material should have sufficient hardness and wear resistance. Commonly used materials include carbide, high-speed steel, carbon tool steel, etc. At the same time, heat treatment is performed as needed to improve the performance of the material.

How to consider drill bushings maintenance and replacement?

When designing drill bushings, ease of maintenance and replacement should be taken into consideration. For replaceable drill bushings and quick-change drill bushings, the structure should be designed to be easy to disassemble and install so that they can be quickly replaced when they need to be replaced. At the same time, the wear of the drill bushing should be taken into consideration, its service life should be reasonably designed, and it should be replaced in time after reaching the service life to avoid affecting the processing quality.

Pingback: Custom CNC Parts Manufacturing | Precision CNC Machining Services Near You

Thank you for your support and attention, we provide you with valuable content every day.

Thank you for your support and attention, we provide you with valuable content every day.

Thank you for your support and attention, we provide you with valuable content every day.

Some truly nice and utilitarian information on this site, as well I think the design and style contains excellent features.

Pingback: Countersink Drill Bits Demystified: 7 Critical Applications & Material-Specific Selection Guide

Yeah bookmaking this wasn’t a bad decision outstanding post! .

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.

You completed certain fine points there. I did a search on the topic and found mainly folks will have the same opinion with your blog.

Unquestionably believe that which you said. Your favorite justification appeared to be on the net the easiest thing to be aware of. I say to you, I definitely get annoyed while people think about worries that they plainly don’t know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side-effects , people can take a signal. Will likely be back to get more. Thanks

There are some fascinating points in time in this article however I don’t know if I see all of them center to heart. There is some validity however I will take hold opinion until I look into it further. Good article , thanks and we wish more! Added to FeedBurner as well

certainly like your web site but you have to test the spelling on several of your posts. A number of them are rife with spelling problems and I find it very bothersome to inform the truth on the other hand I?¦ll definitely come again again.