In the manufacturing industry, CNC (computer numerical control) machining is widely used due to its high degree of accuracy, efficiency and adaptability. When a company or individual needs to customize parts or components, obtaining a CNC machining quote becomes a key part of the decision-making process. Interpretation of CNC machining quotations is not only related to cost control issues, but also directly related to final product quality and delivery issues. This article will guide you in effectively interpreting CNC machining quotes to ensure you make an informed decision.

What is CNC Machining Quote?

CNC (computer numerical control) processing quotation means that in the process of providing CNC processing services to customers, the processing service provider or manufacturer will make a quotation, processing complexity, quantity, required processes, etc. and give a specific cost estimate based on the specific needs of the part design and the type of materials used. This quotation provides an important basis for customers to determine whether to entrust processing, and to compare prices and service quality of different service providers.

What Information is Included in CNC Machining Quotes?

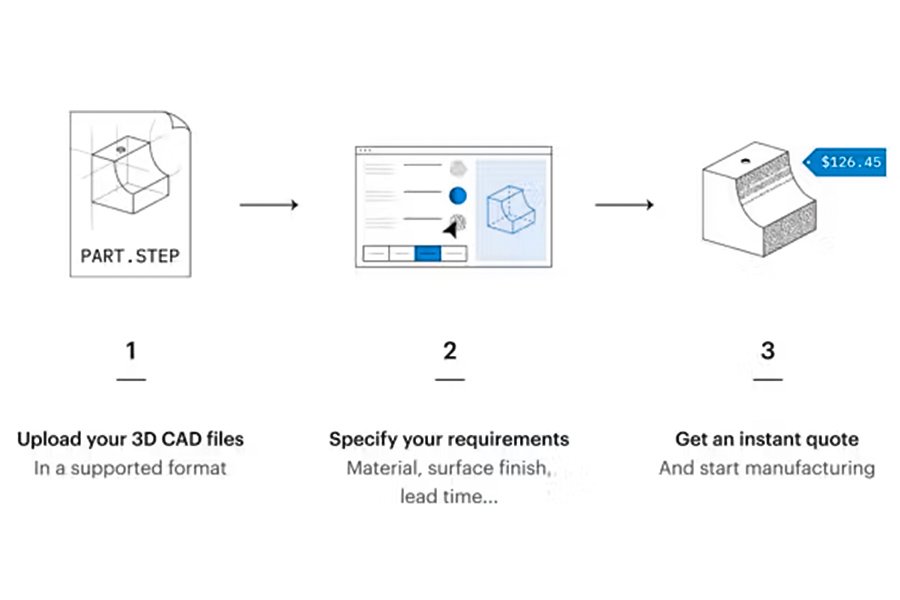

To receive an accurate CNC machining quote, it’s important to provide the following information:

- Part Design Files:Submit CAD files (such as STEP, IGES, or STL) to ensure the part can be accurately machined. The files should clearly indicate dimensions, tolerances, and any special features.

- Material Requirements:Clearly specify the type of material (e.g., aluminum, stainless steel, plastic) and any grade or specifications (e.g., 6061 aluminum, 316 stainless steel) that the part should be made from.

- Quantity:Provide the number of parts you need. Bulk orders can often reduce the price per unit, while one-off parts may have a higher cost.

- Surface Finishes:If your part requires any surface finishing such as anodizing, painting, or coating, make sure to include that information in your request.

- Tolerance and Specifications:Define any critical tolerances your part must meet. Tight tolerances usually require more precise machining and can increase the cost.

- Lead Time:Let the supplier know your desired lead time or delivery deadline. Shorter lead times might result in additional charges.

How to Interpret CNC Machining Quotes?

A CNC machining quote is a detailed estimate of the cost of CNC (computer numerical control) machining services. This quote is usually based on several factors, including but not limited to the size of the part, material type, processing complexity, quantity, delivery time, and some additional services. The following is a detailed explanation of CNC machining quotations:

| Interpretation | Description |

| Breakdown of Costs | Review each component of the quote for transparency. Look for costs associated with material, machine time, setup, tooling, finishing, and shipping. |

| Understanding Units | CNC machining quotes typically include pricing per part, per unit of time (such as hours of machine time), and per material used. |

| Consider Tolerances | If your part requires tight tolerances, this can increase the cost. Ensure that the quote accounts for the level of precision needed. |

| Evaluate Material Specifications | Double-check that the quoted material matches your required specifications (e.g., grade of aluminum, stainless steel, or plastic). |

| Additional Services | Be sure to understand if additional services (such as assembly, quality control, or coating) are included in the quote or if they will incur additional charges. |

How to compare quotes for CNC machining?

When we compare CNC machining quotations, we must consider from multiple angles, and the following are a few specific comparison techniques:

- Total cost: When comparing the overall price, you also need to carefully consider the aspects covered by the price, such as tool selection, configuration settings, and post-processing. This is because cost is a very important factor when choosing a service. Although a lower offer may be more economical in the early stages, this can lead to missing out on critical services.

- Quality of materials and equipment: Verify that the materials provided meet the standards you have set, and confirm that the machine shop uses advanced or outdated equipment.

- When and how to deliver: An increase in turnaround speed can lead to an increase in costs. In this article, we look at how to optimize lead times to reduce overall costs. Explore how delivery times have an impact on prices and delivery schedules.

- Tolerances and precision: We ensure that the required tolerances and precision have been fully taken into account. If all these requirements are not included in the quotation, they must be checked before proceeding with production. If a high tolerance rate is not included in the quotation, there may be defects or rework.

- Service Level: Evaluate the customer service provided by the company, including their clear communication, support, and ability to deliver on their commitments.

Why are CNC machining costs so high?

CNC manufacturing is expensive and here are the reasons why:

- Over-Engineered Designs: Specifying unnecessarily tight tolerances, excessive surface finishes, or complex geometries increases costs significantly.

- Low Material Utilization: Selecting materials without considering waste leads to higher raw material expenses.

- Inefficient Production Runs: Ordering too few parts or splitting orders across multiple suppliers increases setup costs.

- Custom Tooling: If your design requires non-standard cutting tools, suppliers may charge for tool development and procurement.

How to Get a Competitive CNC Machining Quote?

To obtain competitive CNC machining quotes, you may consider the following strategies:

- Request multiple quotes:Contact with multiple CNC machining service providers and get quotes from them. Pay attention to choose the right supplier when quoting. By comparing the pricing strategies of different suppliers, you can have a deeper understanding of the market and make a more fair evaluation of your project.

- For a batch discount: If you expect a large number of orders, please contact the supplier to understand the discount on batch or duplicate orders. Because suppliers often negotiate the volume size with retailers based on the price. In order to better attract large customers, many suppliers tend to offer more attractive quotes for large numbers of orders.

- Explore multiple aspects of additional services: While consulting CNC machining services, further ask if suppliers can provide additional value-added services such as assembly, packaging or design. These services include the installation, repair and replacement of products / components, and other related work. Although these services have the potential to raise overall costs, they have the potential to save you valuable time, reduce financial stress, and in some cases may help reduce overall overhead. Also, if you need to add some features to the product, then you should also consider the benefits of additional services.

Therefore, it is very important to understand the specific cost of these additional services when asking for quotes, which will enable you to make more thoughtful cost estimates.

LS: Quotation process for precision machined parts

Imagine that LS is serving a customer with clear needs. They urgently need to process a batch of stainless steel parts. The specific specifications are as follows:

- Preliminary inquiry stage: The company only provided a simplified drawing, which did not specify the tolerance range and required surface treatment process. Therefore, the quotation range given by LS Company was relatively wide, between 200 and 400 yuan per piece.

- Quote after improving the information: Subsequently, the company submitted detailed technical drawings, clarified the tolerance requirements of ±0.05mm, and specified the 2B surface treatment standard. Based on this, LS Company’s quotation range has been narrowed to 280 to 320 yuan/piece.

- Confirmation of mass production quotation: When the order quantity was confirmed to be 1,000 pieces, LS Company provided a more accurate quotation, which was 265 yuan per piece.

Conclusion: By implementing a standardized inquiry process, the dispersion of quotations was significantly reduced, from the initial difference of 200 yuan to the final 55 yuan, and the accuracy of quotations increased by 72.5%.

Why partner with LS for cost-effective CNC machining?

By choosing our precision CNC machining manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent CNC machining solutions for your project.

Multi material machining

We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of cnc parts you need to process.

Customized services

Provide customized solutions based on customer design requirements and specifications to ensure that CNC parts meet their unique needs.

Competitive pricing

We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

Rapid delivery

We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

Conclusion

CNC machining quotation is an important basis for customers to choose manufacturers and make decisions. By understanding the composition of a quotation and how to understand it, customers can better grasp their needs and find the manufacturer with the highest cost performance. At the same time, by optimizing design, comparing multiple products, and establishing long-term cooperative relationships, customers can further optimize their quotations and reduce costs. In today’s increasingly competitive manufacturing industry, understanding and optimizing CNC machining quotations is of great significance to improving product competitiveness and reducing production costs.

Contact us now to get exclusive CNC machining solutions!

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

How to explain CNC machining?

CNC machining (Numerical Control Machining) is a technology that uses pre-written programs to control machine tools for automated processing. This technology inputs instructions through the computer to accurately control the tool motion trajectory, cutting speed, feed amount and other parameters of the machine tool, thereby achieving efficient and precise processing of parts of various shapes and sizes. CNC machining is widely used in metal cutting, milling, drilling, grinding and other fields, and is an indispensable part of modern manufacturing.

How to read CNC?

CNC is the abbreviation of Computer Numerical Control, which represents a technology that uses computer programs to control machine tools for processing. When reading CNC, our main concern is the program behind it. These programs usually consist of a series of instructions to instruct the machine tool how to move the tool, when to cut, and how deep to cut. The reading and interpretation of CNC programs is usually completed by the interpreter of the CNC machine tool, which converts the program instructions into electrical signals that the machine tool can understand, thereby controlling the movement of the machine tool.

How to estimate CNC machining time?

Estimating CNC machining time usually requires considering multiple factors, including the complexity of the part, the length of the machining path, cutting speed, feed rate, and machine tool performance. A simple method is to use CAM (computer-aided manufacturing) software to simulate the machining process and estimate the machining time based on the simulation results. In addition, experienced engineers can also make a rough estimate based on part drawings and processing requirements, combined with the actual performance of the machine tool. However, it should be noted that the actual processing time may deviate due to various factors.

What is an interpreter for CNC machine tools?

The interpreter of a CNC machine tool is a software or hardware component that converts CNC programs (usually composed of G codes and M codes) into electrical signals that the machine tool can understand. The interpreter is responsible for reading each instruction in the CNC program and converting these instructions into corresponding control signals according to the characteristics and processing requirements of the machine tool, thereby controlling the machine tool’s tool movement, spindle speed, coolant switch, etc. The accuracy and efficiency of the interpreter are crucial to ensuring the accuracy and efficiency of CNC machining.

Pingback: How to Negotiate CNC Machining Quotes?

You actually make it seem really easy along with your presentation but I to find this matter to be actually one thing that I think I would never understand. It seems too complicated and very broad for me. I’m taking a look ahead on your subsequent publish, I¦ll try to get the cling of it!

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.