CNC milling machining is a technology that offers many benefits over traditional milling methods, including precision, efficiency, versatility, and reduced costs and waste. However, like any other technology, CNC milling machines require regular maintenance and occasional repairs to ensure their optimal performance. we will explore how to maintain and repair CNC milling machine parts.

Importance of Regular Maintenance

Regular maintenance is essential to ensure the optimal performance of CNC milling machines. Maintenance helps prevent breakdowns, reduces downtime, and extends the machine’s lifespan. Regular maintenance includes cleaning, lubrication, and inspection of the machine’s components.

Cleaning and Lubrication

Cleaning and lubrication are essential steps in maintaining CNC milling machines. Dirt, debris, and other contaminants can accumulate on the machine’s components, causing damage or affecting its performance. Regular cleaning and lubrication can help prevent this.

Inspection

Inspection is another critical aspect of maintaining CNC milling machines. Regular inspections can help identify potential issues before they become serious problems. Inspections should include checking the machine’s components for wear and tear, misalignment, and other issues.

Repairs

Despite regular maintenance, CNC milling machines may require repairs from time to time. Repairs can range from minor adjustments to major component replacements. It is essential to address any issues promptly to prevent further damage to the machine.

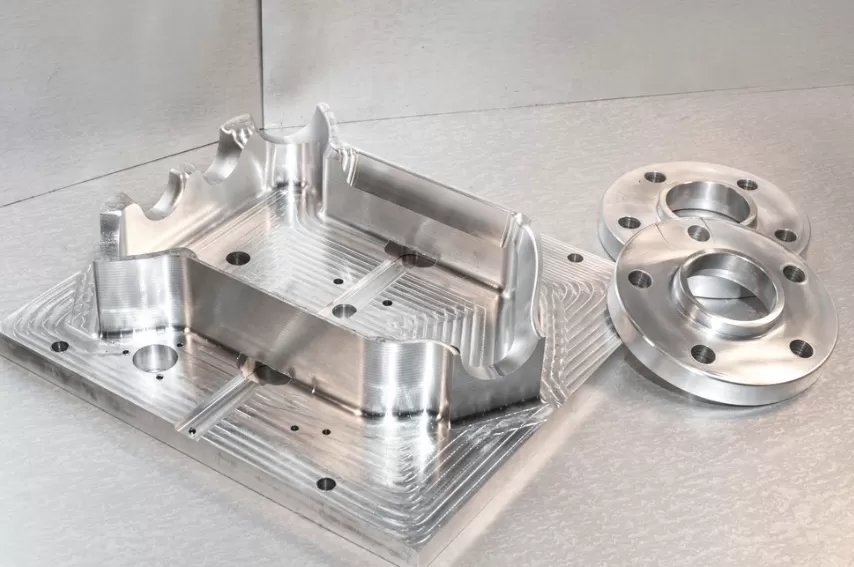

Common CNC Milling Machine Parts to Maintain and Repair

Several components of a CNC milling machine require regular maintenance and occasional repairs. These include the spindle, cutting tool, workholding system, control system, and coolant system.

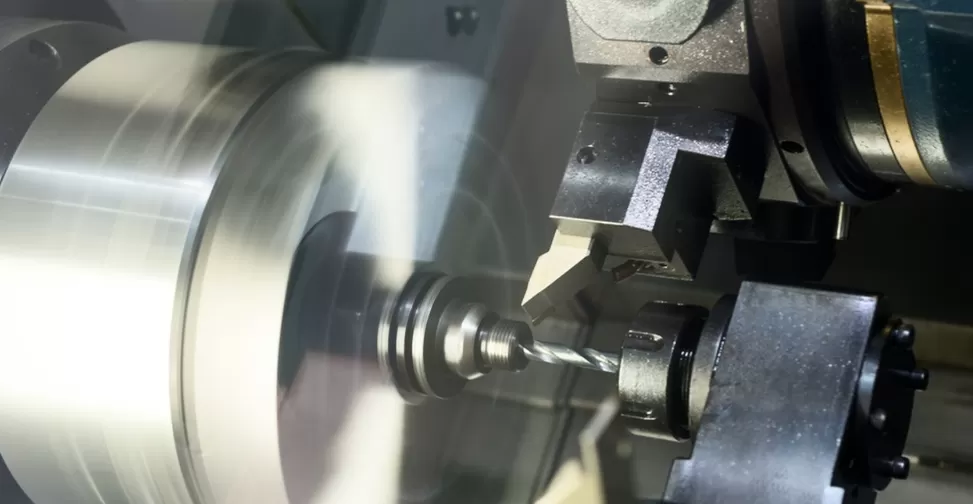

Spindle

The spindle is responsible for rotating the cutting tool and removing material from the workpiece. Regular maintenance of the spindle includes cleaning, lubrication, and inspection of its components. Repairs may include replacing bearings, belts, or other components.

Cutting Tool

The cutting tool is responsible for removing material from the workpiece. Regular maintenance of the cutting tool includes sharpening or replacing the tool and inspecting it for wear and damage.

Workholding System

The workholding system is responsible for holding the workpiece in place during the milling process. Regular maintenance of the workholding system includes cleaning, lubrication, and inspection of its components. Repairs may include replacing clamps, screws, or other components.

Control System

The control system is responsible for managing the movement of the cutting tool and the workpiece during the milling process. Regular maintenance of the control system includes cleaning, inspection, and software updates.

Coolant System

The coolant system is responsible for keeping the cutting tool and workpiece cool during the milling process. Regular maintenance of the coolant system includes cleaning, inspection, and refilling the coolant.

Conclusion

Maintaining and repairing CNC milling machine parts is essential to ensure their optimal performance. Regular maintenance, cleaning, lubrication, and inspection can help prevent breakdowns and extend the machine’s lifespan. Repairs should be addressed promptly to prevent further damage. By following these maintenance and repair tips, you can ensure that your CNC milling machine operates at its best.

If you’re interested in learning more about maintaining and repairing CNC milling machine parts, be sure to consult with experts in the field to determine the best solutions for your specific needs and requirements.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items