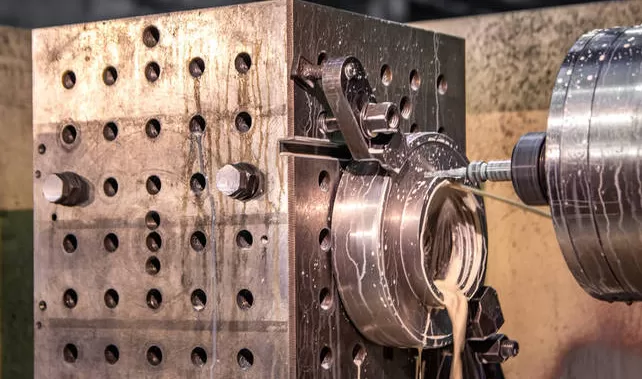

CNC milling machining is a powerful manufacturing process that offers many advantages over traditional manual machining methods. By using computer-controlled machines to shape and cut materials, CNC milling machines are able to produce high-quality and precise parts at a faster rate than ever before. However, to get the most out of your CNC milling machine, you need to optimize your machining process. Here are some tips to help you do just that.

1. Use the Right Cutting Tools

One of the most important factors in optimizing your CNC milling machining process is using the right cutting tools. The cutting tool you use will depend on the material you are machining, the shape of the part, and other factors. Using the wrong cutting tool can result in poor-quality parts, increased wear on the tool, and other issues. Make sure to choose the right cutting tool for the job and keep it sharp to ensure the best results.

2. Optimize Your Tool Path

The tool path is the path that the cutting tool follows as it moves across the workpiece. Optimizing your tool path can help you reduce machining time, improve accuracy, and reduce wear on the tool. Consider using CAM software to generate a tool path that minimizes the number of tool changes and the distance the tool needs to travel.

3. Minimize Material Waste

Minimizing material waste is another important factor in optimizing your CNC milling machining process. CNC milling machines are capable of producing parts with minimal waste, but you can further reduce waste by using the right cutting parameters, such as feed rates and spindle speeds. Make sure to also use the right clamping and fixturing techniques to ensure that the workpiece is held securely and does not move during the machining process.

4. Monitor Your Machine

Monitoring your CNC milling machine is essential to optimizing your machining process. By monitoring the machine, you can identify potential issues before they become major problems. Consider using IoT technology to monitor machine performance and identify areas for improvement. Regular maintenance and cleaning will also help ensure that your machine is performing at its best.

5. Invest in Training

Investing in training is another key factor in optimizing your CNC milling machining process. Make sure that your operators are properly trained in the use of the machine, including programming, tool selection, and maintenance. Consider providing ongoing training to keep your operators up-to-date on the latest techniques and technologies.

By following these tips, you can optimize your CNC milling machining process and get the most out of your machine. Whether you are a manufacturer looking to increase production efficiency or a hobbyist looking to create custom parts, CNC milling machining is a versatile and valuable tool to have in your arsenal.

6. Consider Automation

Automation is becoming increasingly common in CNC milling machining, and for good reason. By automating certain tasks, such as loading and unloading workpieces, manufacturers can increase efficiency and reduce labor costs. Robotics can also improve safety by reducing the need for human operators to be in close proximity to the cutting tool. Consider automating certain tasks to improve the efficiency of your machining process.

7. Keep Up with Technology

The field of CNC milling machining is rapidly evolving, with new technologies and trends emerging all the time. To stay ahead of the competition and optimize your machining process, it’s important to keep up with the latest developments in the field. Consider attending industry conferences and trade shows, reading industry publications, and networking with other professionals in the field.

8. Continuously Improve

Continuous improvement is key to optimizing your CNC milling machining process. By constantly seeking out ways to improve your process, you can reduce waste, improve efficiency, and produce higher-quality parts. Consider implementing a continuous improvement program that involves regular monitoring, analysis, and improvement of your machining process.

Conclusion

Optimizing your CNC milling machining process is essential to getting the most out of your machine. By using the right cutting tools, optimizing your tool path, minimizing material waste, monitoring your machine, investing in training, considering automation, keeping up with technology, and continuously improving your process, you can produce high-quality and precise parts at a faster rate than ever before. Whether you are a manufacturer looking to increase production efficiency or a hobbyist looking to create custom parts, optimizing your CNC milling machining process is a valuable investment that will pay off in the long run.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items