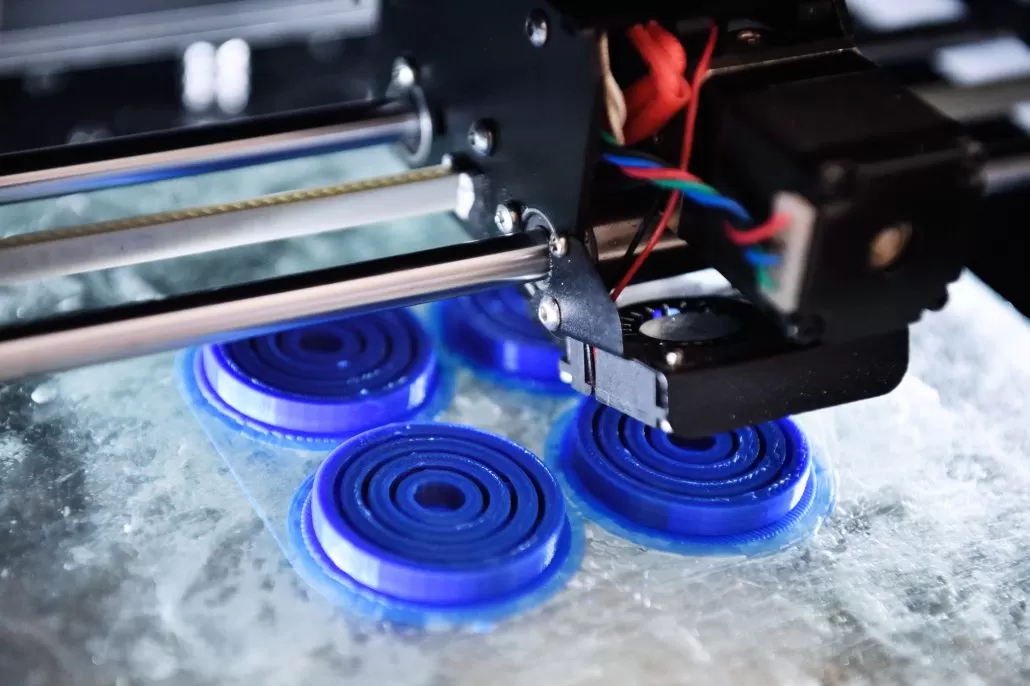

Rapid prototyping is an essential part of the product development process for many businesses. It allows companies to test their designs and ideas before investing in costly production processes. However, prototyping can be expensive, especially when using traditional manufacturing methods. Fortunately, with the advent of 3D printing, companies now have access to a cost-effective and efficient solution to reduce prototyping costs. Here are some ways 3D printing can help you reduce rapid prototyping costs:

Reduced Material Costs

One of the most significant benefits of 3D printing is that it is an additive manufacturing process. This means that you only use the exact amount of material that you need to create the prototype. Traditional manufacturing processes often require more material than is actually required, resulting in wastage and increased costs. With 3D printing, you can reduce material costs by only using the exact amount of material required, reducing waste and saving money.

Faster Turnaround Time

With 3D printing, you can quickly create a prototype in-house, without having to wait for a third-party manufacturer to produce it. This allows you to iterate and refine your design much faster, reducing the time and cost associated with multiple rounds of prototyping. Faster turnaround time means that you can get your product to market faster, giving you a competitive advantage and saving you money.

Reduced Labor Costs

3D printing also reduces labor costs, as it requires minimal human intervention. Traditional manufacturing processes often require skilled labor to operate machinery, resulting in higher labor costs. With 3D printing, you need fewer skilled workers, and the process is automated, which means that you can save money on labor costs.

Customization

With 3D printing, you can easily customize your prototypes to meet your specific needs. This is especially useful for creating complex geometries and unique shapes that would be difficult or impossible to produce using traditional manufacturing processes. Customization allows you to create a prototype that meets your exact specifications, saving you money on design changes.

Reduced Tooling Costs

Another advantage of 3D printing is that it eliminates tooling costs associated with traditional manufacturing methods. Tooling costs can be significant, especially for complex products that require multiple molds or dies. With 3D printing, you can create complex parts without the need for expensive tooling, reducing costs and increasing efficiency.

Improved Product Quality

3D printing also allows for improved product quality by providing better accuracy and precision in the manufacturing process. This means that you can create prototypes that are more similar to the final product, reducing the need for multiple iterations and further reducing costs.

Sustainability

In addition to its cost-effectiveness, 3D printing also has environmental benefits. Traditional manufacturing processes often result in wastage, which can have a significant impact on the environment. With 3D printing, you only use the exact amount of material required, which reduces waste and promotes sustainability.

Overall, 3D printing is a cost-effective and efficient solution for rapid prototyping that can help you create high-quality prototypes at a fraction of the cost of traditional methods. By reducing material and labor costs, speeding up turnaround times, allowing for customization, eliminating tooling costs, improving product quality, and promoting sustainability, 3D printing can help you save money and bring your products to market faster.