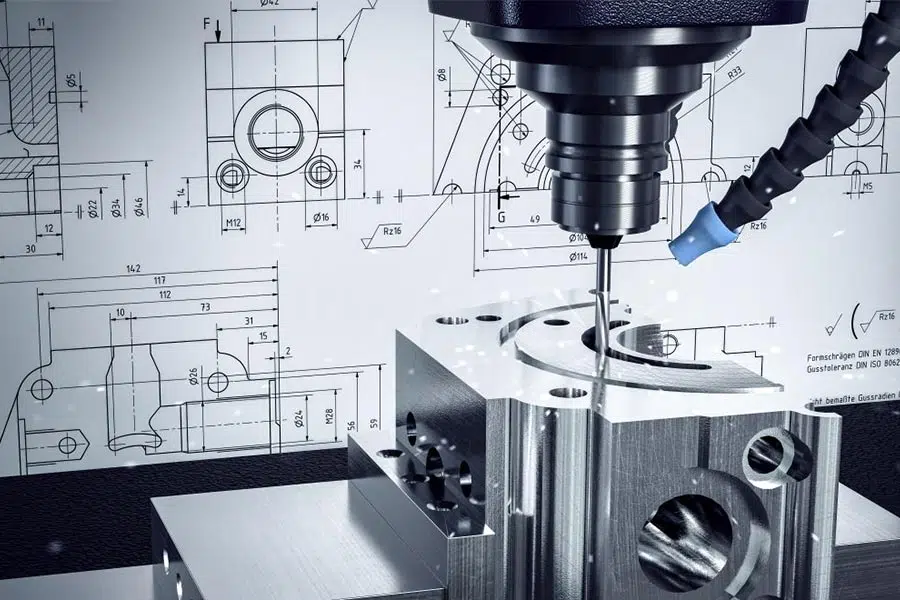

In the field of high-precision manufacturing, CNC (computer numerical control) machining methods have penetrated into key links in many industries due to their excellent accuracy and efficiency. In these fields, customers have high requirements for machine tool performance, ease of operation and after-sales service. However, for those companies or individuals seeking CNC machining services, how to obtain an accurate and transparent quotation has become a core factor in determining the success of the project. How to determine a good quote quickly and effectively? Today, we plan to conduct in-depth research on this topic and present you with practical trading advice.

What does online CNC machining quotation mean?

Clear definition and characteristic

definition:

Online CNC machining quotation is a CNC machining service quotation method based on Internet technology. Customers can quickly obtain CNC machining prices by uploading drawings, selecting materials, specifying processing requirements, etc.

characteristic

- Real-time: With the help of online tools or systems, quotes can be generated in real time or quickly, thereby shortening the waiting time.

- Convenience: Customers do not need to go to the processing factory in person, nor do they need to inquire by phone or email, they can complete the quotation application only through the Internet.

- Accuracy: The online quotation system usually automatically calculates the processing cost based on the drawings and processing requirements provided by the customer in order to give a more accurate quotation.

How It Works:

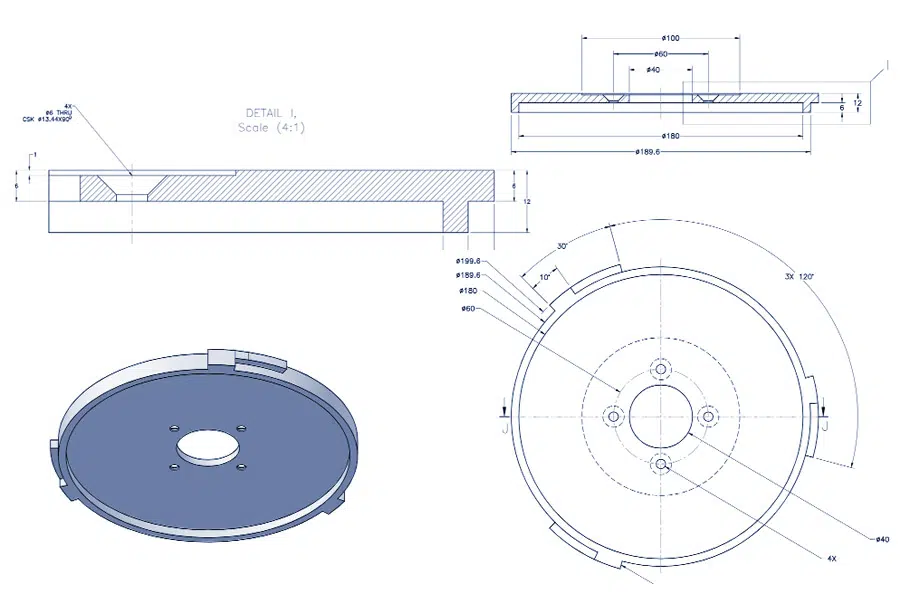

- File Upload: Customers upload design files in formats like STEP, IGES, or STL.

- Parameter Selection: Users specify material type, surface finish, quantity, and required tolerances.

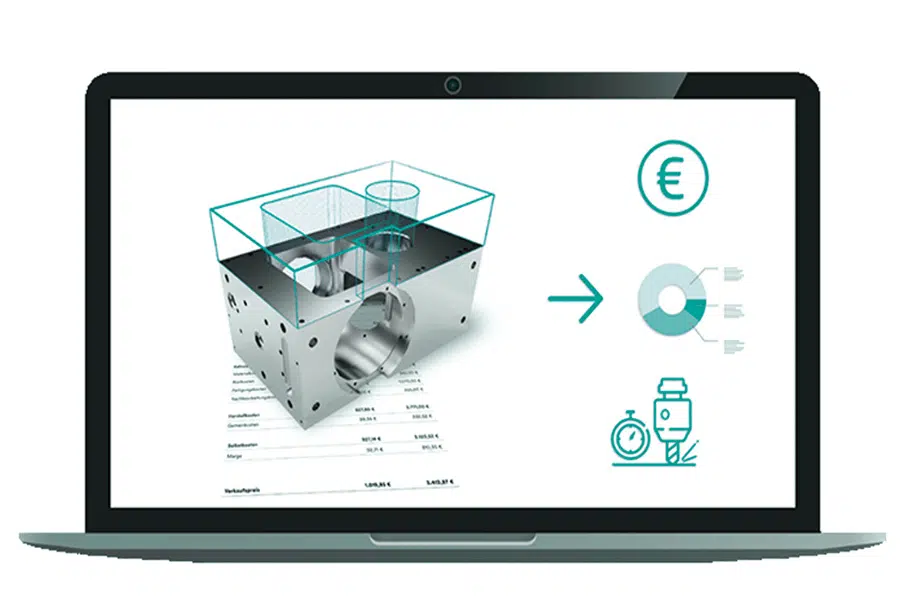

- Real-Time Pricing: The platform analyzes the input and generates an instant quote.

- Order Placement: After approval, the project moves to production.

How to Request an Accurate CNC Machining Quote?

In the high-precision manufacturing industry, getting an accurate CNC machining quote is one of the key factors in ensuring your project goes smoothly. To ensure that the quote you provide is accurate, here are a few key steps and suggestions:

- We provide detailed part drawings to ensure the clarity and accuracy of the drawings, which include all key information of the parts, such as dimensions, tolerances, material specifications and surface finish, etc. The accuracy of the quote is directly affected by the level of detail in the drawings.

- Regarding the specified materials and surface treatments, it is necessary to clarify the various materials required for parts manufacturing, such as aluminum alloys, stainless steel, and plastics. Please describe in detail all necessary surface treatment steps such as anodizing, coating, polishing, etc. Choosing the right materials and surface treatments can have a significant impact on the cost of the mold and the final quote.

- Be clear about quantities and delivery dates,Set the quantity for the order, as larger batches have the potential to reduce production costs per part, and provide any final delivery dates or delivery times required, as there may be additional value in speeding up production.

- When evaluating the machining complexity and precision requirements of a part, we need to consider the impact that these factors may have on the time and cost of machining. For complex parts, more sophisticated tooling and longer manufacturing cycles may be required, which may result in higher costs.

- Communicate with suppliers, ensure in-depth communication with CNC machining suppliers, so that they have a full understanding of the needs and expectations of parts, and ask suppliers about processing capabilities, equipment status and experience to ensure that they can meet the processing requirements of parts.

- Collect and compare quotations, submit part drawings and requirements to multiple CNC machining suppliers to obtain their quotations, and then compare the quotations, delivery time, quality and service levels of different suppliers in order to make the best choice.

- Verify the specific content of the quotation. Before finalizing the quotation, be sure to verify every detail in the quotation with the supplier and understand whether the quotation covers the cost of materials, processing fees, surface treatment fees and other potential additional costs.

What Information Should I Include in My CNC Machining Quote Request?

To ensure the accuracy and completeness of the CNC quotation, the following core elements should be included when submitting the quotation request:

- Part design drawings: provide the latest CAD or 3D model files with STEP, IGES or STL formats. These documents shall detail the precise dimensions, tolerances, and all geometric features.

- Material Specification: Clearly specify the type or grade of material (such as aluminum, stainless steel, plastic, etc.) you expect to use to manufacturing parts. This step is critical because the material selection will directly affect the processing process and the final pricing.

- Order quantity and frequency: specify the number of parts required and whether the order is disposable or repetitive. Batch or repetitive orders often enjoy a more cost-effective offer.

- Surface treatment and subsequent processing requirements: indicate whether the parts require additional finish, coating, or finishing (e. g., painting, polishing). Subsequent machining steps will affect the overall cost of CNC machining.

- Delivery time and urgency: Please specify the desired delivery schedule. If parts requirements are urgent, expedited services may increase costs. However, looser lead times often help to lower prices.

How to Get a Competitive CNC Machining Quote?

To obtain competitive CNC machining quotes, you may consider the following strategies:

- Request multiple quotes: Contact with multiple CNC machining service providers and get quotes from them. Pay attention to choose the right supplier when quoting. By comparing the pricing strategies of different suppliers, you can have a deeper understanding of the market and make a more fair evaluation of your project.

- For a batch discount: If you expect a large number of orders, please contact the supplier to understand the discount on batch or duplicate orders. Because suppliers often negotiate the volume size with retailers based on the price. In order to better attract large customers, many suppliers tend to offer more attractive quotes for large numbers of orders.

- Explore multiple aspects of additional services: While consulting CNC machining services, further ask if suppliers can provide additional value-added services such as assembly, packaging or design. These services include the installation, repair and replacement of products / components, and other related work. Although these services have the potential to raise overall costs, they have the potential to save you valuable time, reduce financial stress, and in some cases may help reduce overall overhead. Also, if you need to add some features to the product, then you should also consider the benefits of additional services.

Therefore, it is very important to understand the specific cost of these additional services when asking for quotes, which will enable you to make more thoughtful cost estimates.

How Do I Ensure an Accurate CNC Machining Estimate?

To ensure that the CNC machining estimation is accurate, the following key factors are crucial:

- Detailed design drawings and standards, We provide comprehensive and accurate design drawings and specifications to ensure that all tolerances, material specifications, and geometric characteristics are clear and accurate.

- In order to determine the best CNC machining methods (such as milling, turning, etc.), we need deep communication with suppliers, because different processing methods vary in cost and efficiency.

- When considering the cost of materials and tooling, we need to accurately evaluate the cost and availability of the required materials, and also consider whether it is necessary to customize a specific tooling or fixture, as this will have a direct impact on the cost of the tooling.

- Full communication needs,Keep close communication with suppliers to ensure that they fully understand your needs, including quantity, delivery time, etc., to provide accurate estimates.

- Assess potential risks,Identify and evaluate risk factors that may affect processing cost and time, such as technical difficulty, material shortage, etc., and consider corresponding countermeasures in the estimate.

What elements may affect the quotation of CNC machining?

The quotation of CNC machining is affected by multiple factors. What are the dominant factors affecting the CNC machining quotation:

| Factors | Description |

| Requirements for the complexity and accuracy of parts | Designing more complex parts and setting more stringent tolerance standards often lead to increased complexity and time required for processing, leading to higher costs. |

| Types and costs of materials: | The type of material selected, hardness, toughness, and market supply conditions will all have an impact on the processing price, while the cost of rare or difficult-to-process materials is usually higher. |

| Production | The unit cost of mass production is usually lower compared to small batch production, because the fixed cost can be allocated to more parts. |

| Subsequent processing and additional services | Surface treatment, painting, coating and other subsequent processing steps, as well as additional services such as assembly and packaging, which will improve the overall quotation of CNC machining . |

| Geographical location and logistics costs | Labor costs, operating costs, and logistics costs in the supplier’s region will also affect the quotation. |

| Urgent orders and delivery times | If a customer needs to fulfill an order urgently or shorten delivery times, the supplier may need to adjust production plans or work overtime, which may increase cost |

Case study: LS Company’s quotation process for specific parts

A company needs to process a batch of CNC parts, and the selected material is stainless steel.

- Preliminary inquiry stage: The company only provided a simplified drawing, which did not specify the tolerance range and required surface treatment process. Therefore, the quotation range given by LS Company was relatively wide, between 200 and 400 yuan per piece.

- Quote after improving the information: Subsequently, the company submitted detailed technical drawings, clarified the tolerance requirements of ±0.05mm, and specified the 2B surface treatment standard. Based on this, LS Company’s quotation range has been narrowed to 280 to 320 yuan/piece.

- Confirmation of mass production quotation: When the order quantity was confirmed to be 1,000 pieces, LS Company provided a more accurate quotation, which was 265 yuan per piece.

Conclusion: By implementing a standardized inquiry process, the dispersion of quotations was significantly reduced, from the initial difference of 200 yuan to the final 55 yuan, and the accuracy of quotations increased by 72.5%.

Conclusion

Requesting an accurate CNC machining quote is a process that takes multiple factors into consideration. By clarifying part requirements, selecting a suitable machining plant, evaluating machining time, determining machining unit price and material cost, considering additional costs, communicating and negotiating, obtaining a written quotation, and optimizing the quotation strategy, you can ensure a reasonable and accurate quotation. This will help reduce production costs, increase profit margins, and lay a solid foundation for subsequent smooth cooperation.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

What is the accuracy of CNC machining?

The accuracy of CNC machining refers to the degree of consistency between the geometric parameters such as the size, shape, and position of the workpiece obtained when processing by CNC machine tools and the ideal design values. It reflects the accuracy and reliability of the machining process and is an important indicator for measuring the quality of CNC machining. The accuracy of CNC machining is affected by many factors such as machine tool accuracy, tool accuracy, programming accuracy, measurement accuracy, process system stiffness, and thermal deformation.

How to evaluate CNC machining complexity?

Mainly depends on the size and shape of the part, accuracy requirements, material type and surface treatment. Complex shapes and sizes require more complex programming and processing steps; high precision requires precision equipment and strict process control; materials such as carbide are difficult to process and require special tools and processes; additional surface treatments increase complexity.

What elements are usually included in a CNC machining quote?

Key elements of CNC machining quotation: material cost (depending on material, usage and market price), processing expenses (including equipment depreciation, maintenance, labor and indirect costs, calculated in working hours or processes), additional costs (such as transportation, packaging, taxes), profit point (extra cost for supplier profit).

How to ensure the quote is accurate?

The following measures can be taken to ensure accurate CNC machining quotations: Detailed communication: clarify part drawings, processing requirements and quantities with suppliers. Reference market price: Understand the material market price and industry average rates. Required details: Suppliers provide cost details for materials, processing, additional items, etc. Sample testing: Verify sample quality and accuracy before placing an order.

Pingback: What Information Is Needed for a CNC Machining Quote?

Pingback: How to Interpret CNC Machining Quotes?

Pingback: What to Expect in a CNC Machining Quote?

Utterly composed content material, Really enjoyed reading through.

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.

Pingback: CNC Precision Parts: How to Avoid Costly Errors & Source Reliable Suppliers

I’m really enjoying the design and layout of your website. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a developer to create your theme? Fantastic work!

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.