CNC (Computer Numerical Control) machines are widely used in manufacturing industries to produce high-quality products with precision and accuracy. G-code is a programming language used to control CNC machines. It allows you to control the movement of the machine and the tools used to cut, shape, or drill materials. In this article, we will discuss how to use G-code in CNC machines.

Understanding G-code

G-code is a programming language that contains a set of instructions for CNC machines. These instructions are used to control the movement of the machine’s cutting tools. Each G-code command has a specific function and is used to perform a particular task. Some of the common G-code commands used in CNC machines include G00, G01, G02, G03, G04, G17, G18, G19, G20, G21, G28, G40, G41, G42, G43, G49, G54, G55, G56, G57, G58, G59, G61, G64, G90, G91, and G94.

G-code is a language that is understood by CNC machines. It is used to make the machine perform different types of tasks such as cutting, drilling, and shaping materials. The language is made up of a series of instructions that the machine follows to carry out the task at hand. These instructions can be created using a computer-aided design (CAD) software and then converted into G-code by a computer-aided manufacturing (CAM) software.

Creating G-code programs

To create a G-code program, you need to use a computer-aided design (CAD) software to design your part or product. Once you have designed your product, you can use a computer-aided manufacturing (CAM) software to convert the design into G-code instructions that the CNC machine parts can understand.

The CAM software will generate a G-code program that contains all the necessary instructions to produce your product. You can save the G-code program to a USB drive or transfer it directly to the CNC machine using a computer.

It is important to note that the G-code program must be created with precision and accuracy to ensure that the CNC machine performs the task correctly. Any errors or mistakes in the program can result in the machine producing incorrect or imperfect parts.

Setting up the CNC machine

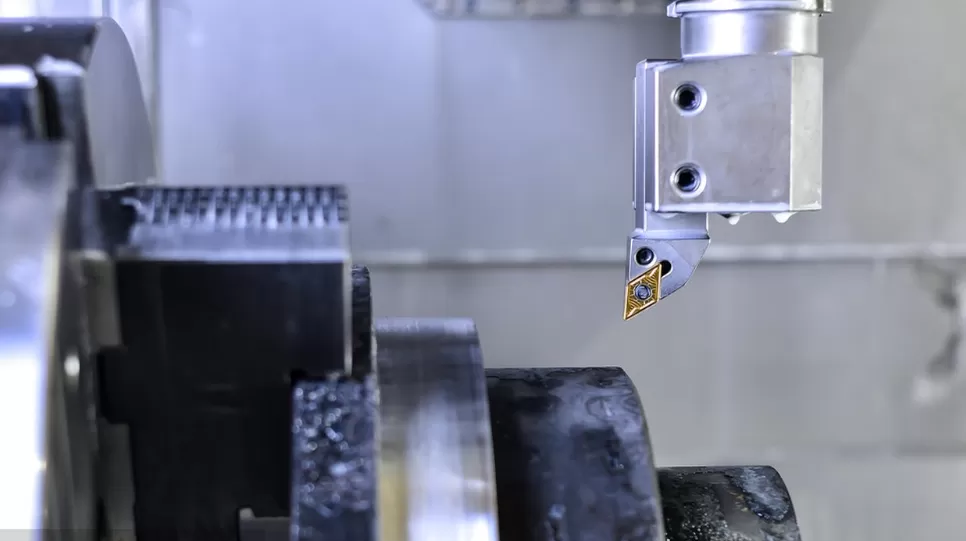

Before you can use the G-code program, you need to set up the CNC machine. This involves attaching the cutting tools to the machine and securing the material to be cut to the machine’s worktable. You also need to set the zero or reference point for the machine. This is the point where the machine will start cutting the material.

Setting up the CNC machine is a crucial step in the process. A poorly set-up machine can result in inaccurate cuts, wasted materials, and even damage to the machine itself. It is important to follow the manufacturer’s instructions carefully when setting up the machine to ensure that it is configured correctly.

Once you have set up the machine, you can load the G-code program into the CNC machine’s control unit. The control unit will interpret the G-code instructions and direct the machine to cut, shape, or drill the material.

Testing the G-code program

Before you start cutting the material, it is important to test the G-code program. This will help you to identify any errors or issues in the program before you start cutting the material.

To test the G-code program, you can use a simulator or a CNC machine with a test material. The simulator will allow you to run the G-code program without cutting any material. This will help you to see how the machine will move and ensure that the program is correct.

If you are using a CNC machine with a test material, you can run the G-code program on the test material to ensure that the machine is set up correctly and that the program is working properly.

Conclusion

G-code is an essential programming language used to control CNC machines. By understanding how to use G-code, you can create accurate and precise parts and products. To use G-code, you need to create a G-code program using a CAD and CAM software, set up the CNC machine, and test the G-code program before cutting the material. With these steps, you can use G-code to produce high-quality products with ease.

When working with G-code, it is important to remember that precision and accuracy are key. Any errors or mistakes in the program can result in the machine producing incorrect or imperfect parts. It is also important to follow the manufacturer’s instructions when setting up the CNC machine to ensure that it is configured correctly. Testing the G-code program before cutting the material is also crucial to identify any issues or errors in the program. With these tips in mind, you can use G-code to create high-quality products with ease.