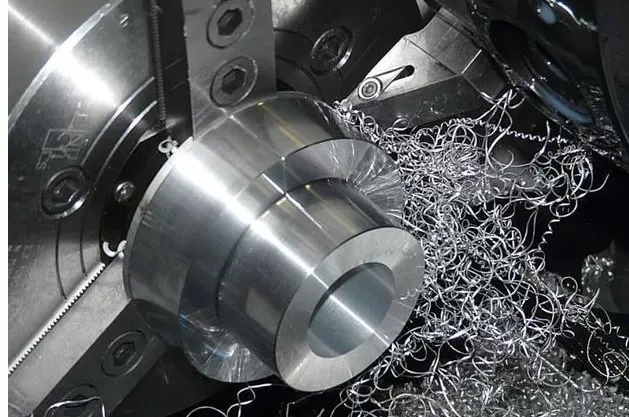

CNC machining is a process that uses computer-controlled machines to create precise and complex parts. It’s a critical process in many industries, including aerospace, defense, and automotive, where precision and quality are paramount. Quality control is an essential aspect of CNC machining, as it ensures that the parts meet the required specifications and standards. In this article, we will discuss the importance of quality control in CNC machining.

Ensures Consistency and Precision

Quality control is essential in CNC machining to ensure consistency and precision. The machines are programmed to create parts with the same specifications every time, but there is still a risk of errors. Quality control measures, such as inspections and testing, help identify and correct any errors in the manufacturing process. This ensures that the parts are of high quality and meet the required standards.

Reduces Waste and Costs

Quality control can help reduce waste and costs in CNC machining. Defective parts can result in production delays, additional costs, and loss of revenue. Quality control measures, such as inspections and testing, help identify defective parts early in the manufacturing process, reducing the need for rework and minimizing waste. This can help reduce costs and increase profitability.

Ensures Customer Satisfaction

Quality control is essential in CNC machining to ensure customer satisfaction. Customers expect high-quality parts that meet their specifications and standards. Quality control measures, such as inspections and testing, help ensure that the parts meet these requirements. This can help build customer trust and loyalty, which is essential for the long-term success of any business.

Ensures Compliance with Industry Standards

Quality control is essential in CNC machining parts services to ensure compliance with industry standards. Many industries, such as aerospace and defense, have strict quality standards that must be met. Quality control measures, such as inspections and testing, help ensure that the parts meet these standards. This can help avoid costly fines and legal issues that could result from non-compliance.

Improves Safety

Quality control is essential in CNC machining to improve safety. Defective parts can result in accidents and injuries, which can be costly and damaging to the reputation of the business. Quality control measures, such as inspections and testing, help identify and correct any safety issues early in the manufacturing process. This can help ensure a safe working environment for employees and customers.

In conclusion, quality control is an essential aspect of CNC machining. It ensures consistency and precision, reduces waste and costs, ensures customer satisfaction, ensures compliance with industry standards, and improves safety. By investing in quality control measures, businesses can improve the quality of their products, increase customer satisfaction, and ensure the long-term success of their business.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items