CNC machining is a versatile manufacturing process that has revolutionized the manufacturing industry in recent years. CNC (Computer Numerical Control) machines are capable of producing complex, high-quality parts with precision and accuracy. Here are some of the industries that heavily rely on CNC machining:

Aerospace Industry

Aerospace precision parts machining,The aerospace industry requires high-quality, precision parts that can withstand extreme conditions. The parts used in aircraft engines, landing gears, and other critical parts need to be durable, lightweight, and capable of withstanding high temperatures and pressures. CNC machining provides the necessary precision and accuracy to produce parts that meet these requirements.

Additionally, CNC machining enables the aerospace industry to produce parts with complex geometries that would be difficult to achieve with traditional manufacturing methods. The aerospace industry also benefits from CNC machining’s ability to produce parts with high accuracy, consistency, and repeatability.

Automotive Industry

Automotive precision parts machining,The automotive industry uses CNC machining to produce high-quality parts with tight tolerances and complex shapes. CNC machines are used to create engine components, transmissions, and other critical parts that require precision and durability. CNC machining provides the necessary precision and accuracy to produce parts that meet these requirements. Additionally, CNC machining enables the automotive industry to produce parts with complex geometries that would be difficult to achieve with traditional manufacturing methods.

Medical Industry

Medical parts machining,The medical industry relies on CNC machining to produce orthopedic implants, surgical instruments, and other medical devices. CNC machines can create parts with high accuracy, consistency, and repeatability. These parts need to meet strict quality standards and be biocompatible to ensure patient safety. CNC machining provides the necessary precision and accuracy to produce parts that meet these requirements. Additionally, CNC machining enables the medical industry to produce customized parts that are tailored to individual patient needs.

Electronics Industry

Electronics precision parts machining,CNC machining is used to produce complex parts for electronic devices, such as computer components, smartphone parts, and circuit boards. CNC machines are capable of producing high-quality parts with tight tolerances and complex shapes. These parts need to be precise and durable to ensure optimal performance and reliability of electronic devices. CNC machining provides the necessary precision and accuracy to produce parts that meet these requirements. Additionally, CNC machining enables the electronics industry to produce parts with complex geometries that would be difficult to achieve with traditional manufacturing methods.

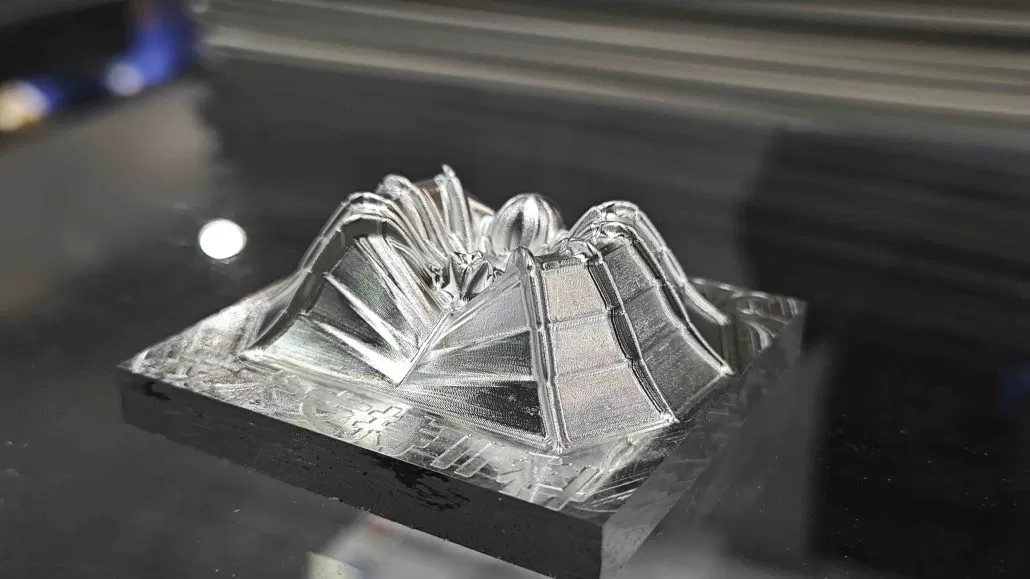

Manufacturing Industry

The manufacturing industry uses CNC machining to produce a wide range of parts and components, including molds, jigs, fixtures, and tooling. CNC machines can create parts with high precision, accuracy, and consistency. These parts need to be precise and durable to ensure optimal performance and efficiency in manufacturing processes. CNC machining provides the necessary precision and accuracy to produce parts that meet these requirements. Additionally, CNC machining enables the manufacturing industry to produce parts with complex geometries that would be difficult to achieve with traditional manufacturing methods.

In conclusion, CNC machining has become an essential tool for creating high-quality, precision parts in diverse industries. From aerospace and automotive to medical and electronics, CNC machining is revolutionizing the manufacturing industry. Its ability to produce parts with complex geometries and tight tolerances makes it a versatile and efficient manufacturing process that can meet the needs of diverse industries. With advancements in technology, CNC machining is expected to continue to play a significant role in the manufacturing industry, providing precision, accuracy, and consistency in producing high-quality parts.