When it comes to manufacturing and prototyping, CNC machining and 3D printing are two popular processes that come to mind. While they share some similarities, they are quite different. In this article, we will explore the differences between CNC machining and 3D printing to help you understand which one might be the best fit for your project.

What is CNC Machining

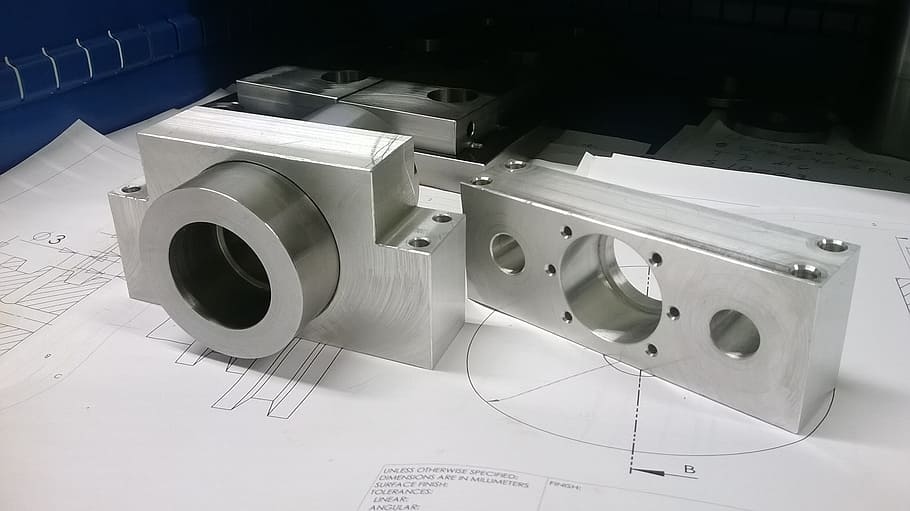

What is CNC machining?CNC machining is a manufacturing process that uses computer-controlled machines to cut and shape materials into precise shapes and sizes. This technology is commonly used for producing metal and plastic parts for a wide range of industries, including aerospace, automotive, and medical. Unlike 3D printing, which builds objects layer by layer, CNC machining removes material from a solid block to create the desired shape. CNC machining is known for its accuracy, speed, and ability to work with a wide range of materials.What is 3D printing

What is 3D printing

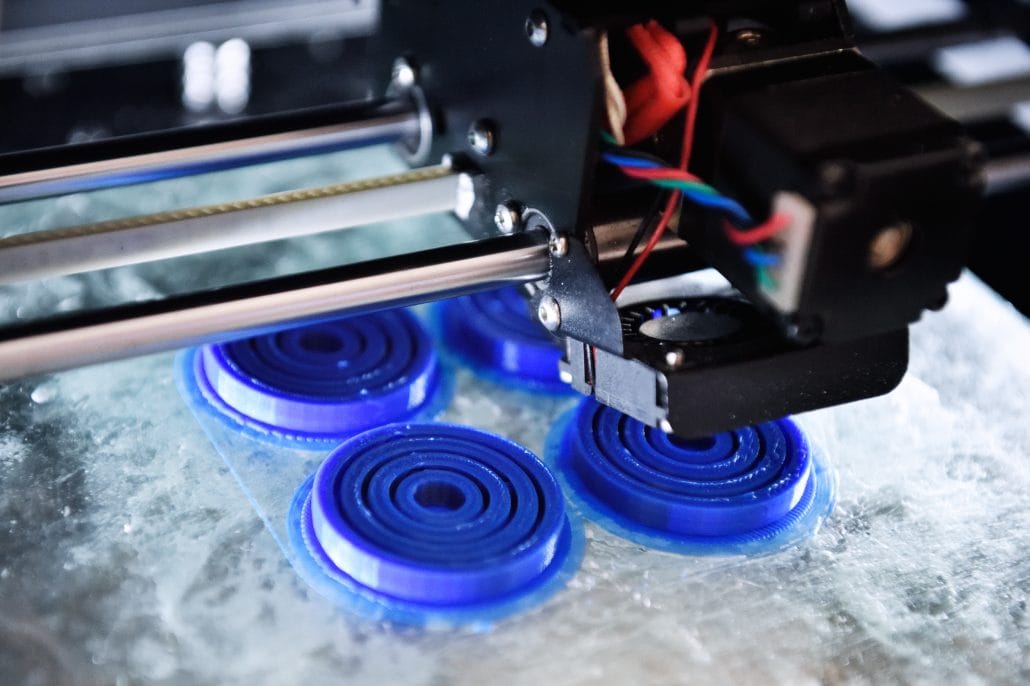

3D printing is a manufacturing process that creates three-dimensional objects from a digital file. The printer builds the object layer by layer until it is complete. This technology, also known as additive manufacturing, has revolutionized the way products are designed and produced. It has a wide range of applications, from prototyping and product development to medical and aerospace industries. 3D printing can use a variety of materials, including plastics, metals, and even living cells. Overall, 3D printing is a versatile and innovative technology that has the potential to transform various industries.

Is CNC Machining the Same Thing as 3D Printing

When it comes to manufacturing and prototyping, two popular processes that come to mind are CNC machining and 3D printing. While both of them share some similarities, they are quite different from each other. In this article, we will explore the differences between CNC machining and 3D printing to help you understand which one might be the best fit for your project.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a block of material. The process starts with a 3D model of the part that needs to be produced. The computer program then sends instructions to the machine, which uses various cutting tools to remove material based on the design.

CNC machining is ideal for producing parts with tight tolerances, high accuracy, and excellent surface finishes. The process can work with a wide variety of materials, including metals, plastics, and composites. However, the setup time for CNC machining can be longer, and it is less suitable for producing complex geometries.

3D Printing

3D printing, also known as additive manufacturing, is a process that builds parts layer by layer using a 3D printer. The printer works by melting or fusing a material, such as plastic or metal, and depositing it layer by layer to create a 3D object. 3D printing is ideal for producing complex geometries and prototypes quickly and cost-effectively.

While 3D printing is not as precise or accurate as CNC machining, it is more versatile when it comes to producing complex geometries. It is also more suitable for producing small volumes of parts or prototypes.

In conclusion, CNC machining and 3D printing are two different manufacturing processes that have their advantages and disadvantages. CNC machining is ideal for producing parts with high precision, tight tolerances, and excellent surface finishes, but it is less suitable for complex geometries. 3D printing, on the other hand, is perfect for producing complex geometries quickly and cost-effectively, but it is not as precise or accurate as CNC machining.

When deciding which process to use, it is essential to consider the specific needs of your project. If you need a part with high precision and tight tolerances, CNC machining is the way to go. If you need a prototype quickly and cost-effectively or require a complex geometry, 3D printing might be the better option.

Is 3D printing harder than CNC

3D printing and CNC (Computer Numerical Control) machining are two different manufacturing processes with their own strengths and weaknesses. However, it’s difficult to say which one is harder as it depends on the specific project and the user’s experience.

3D printing is generally considered easier to learn and use compared to CNC machining. With 3D printing, users can create complex shapes and designs without having to go through a lot of setup time. It’s also easier to make changes to a design and iterate quickly with 3D printing.

CNC machining, on the other hand, requires more setup time and expertise to use effectively. Users need to be proficient in CAD (Computer-Aided Design) software and have a good understanding of machining principles. CNC machining is better suited for creating high-precision parts with tight tolerances.

In summary, both 3D printing and CNC machining have their own learning curves and require different skill sets. So, it’s hard to say which one is harder without knowing the specific project and the user’s experience.

Advantages of 3D Printing vs CNC Machining

3D printing and CNC machining are two ways of manufacturing products. While both methods have their pros and cons, there are some distinct advantages of 3D printing over CNC machining.

Here are two advantages of 3D printing over CNC machining:

- Design Flexibility: One of the main advantages of 3D printing is the design flexibility it offers. With 3D printing, it is possible to create more complex shapes and designs that are difficult or impossible to achieve with CNC machining. For example, 3D printing allows for the creation of designs with internal structures, overhangs, and complex geometries that would be difficult or impossible to machine. This design flexibility is especially useful in fields such as aerospace, automotive, and medical devices, where complex shapes and structures are often required.

- Cost-Effectiveness for Small Production Runs: Another advantage of 3D printing over CNC machining is cost-effectiveness for small production runs. CNC machining is most cost-effective for large production runs, while 3D printing is more cost-effective for small production runs. This is because 3D printing does not require the same high setup costs as CNC machining, making it a more viable option for small-scale production runs. Additionally, 3D printing allows for the creation of customized products, which can be more expensive to produce using CNC machining.

Overall, while CNC machining still has its place in manufacturing, 3D printing offers unique advantages that make it an attractive option for certain applications.

Will 3D Printing Replace CNC Machining

CNC machining has been the go-to process for manufacturing high-quality, precision parts for decades. However, with the advent of 3D printing technology, there has been a lot of discussion about whether 3D printing will eventually replace CNC machining.

While 3D printing has come a long way in recent years, it is still not quite ready to replace CNC machining entirely. CNC machining is still the preferred method for producing high-quality parts with tight tolerances, complex geometries, and a wide range of materials.

That being said, 3D printing is an excellent complementary technology to CNC machining. 3D printing can be used to produce complex, low-volume parts quickly and efficiently, which would be difficult or impossible to produce with CNC machining. Additionally, 3D printing is an excellent prototyping tool, allowing engineers to quickly iterate and test designs before committing to expensive CNC machining.

In conclusion, while 3D printing is an exciting technology that is rapidly advancing, it is not likely to replace CNC machining anytime soon. CNC machining is still the gold standard for high-quality, precision parts, but 3D printing is an excellent complementary technology that can enhance the manufacturing process in many ways.

How to Choose Between 3D Printing and CNC Machining

When it comes to manufacturing parts or prototypes, two popular options are 3D printing and CNC machining. Both have their advantages and disadvantages, and choosing between them depends on several factors.

Complexity of Design

3D printing is ideal for complex designs with intricate details. It can produce parts with overhangs, undercuts, and internal cavities that would be difficult or impossible to make with CNC machining. CNC machining, on the other hand, is better suited for simpler designs with fewer details.

Material Selection

The range of materials available for 3D printing is expanding, but it is still limited compared to the range of materials that can be machined. CNC machining can work with a wide variety of materials, including metals, plastics, and composites.

Quantity and Timeframe

3D printing is ideal for producing small quantities of parts quickly, while CNC machining is better suited for large quantities of parts. Additionally, 3D printing is generally faster than CNC machining for small quantities, but CNC machining becomes more efficient as the quantity increases.

Cost

The cost of 3D printing and CNC machining can vary depending on several factors. 3D printing is generally more cost-effective for small quantities of parts, while CNC machining becomes more cost-effective for larger quantities. Additionally, the complexity of the design can affect the cost of both methods.

Choosing between 3D printing and CNC machining requires considering several factors, including the complexity of the design, material selection, quantity and timeframe, and cost. Ultimately, the decision should be based on which method is best suited for the specific project at hand.

In conclusion, CNC machining and 3D printing are two different manufacturing processes that have their advantages and disadvantages. When deciding which process to use, it is essential to consider the specific needs of your project. If you need a part with high precision and tight tolerances, CNC machining is the way to go. If you need a prototype quickly and cost-effectively or require a complex geometry, 3D printing might be the better option.