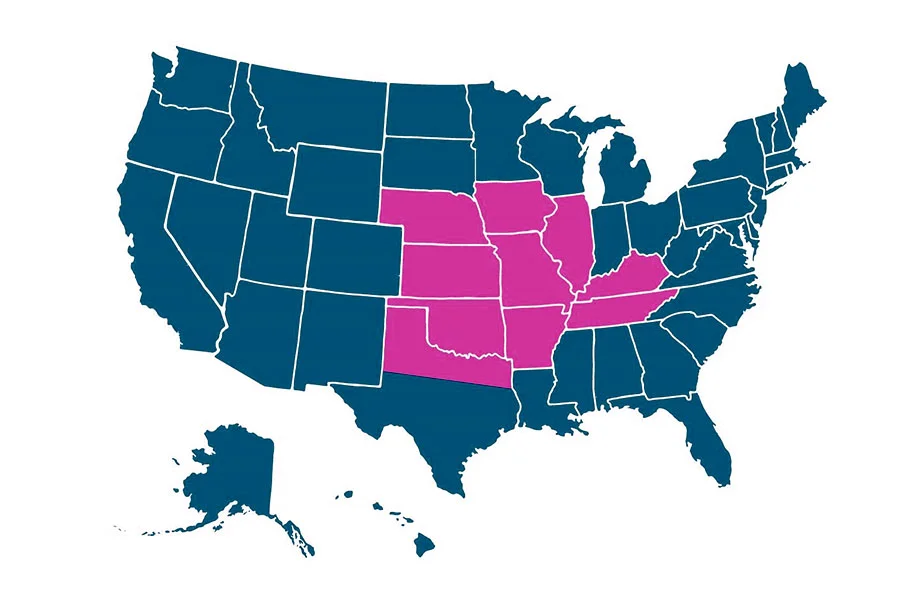

When we explore Nebraska, an important state in the Midwest, we often think of its vast farmland and abundant agricultural resources. However, besides agriculture, Nebraska also has a place in the manufacturing sector. Especially in the casting industry, although no specific company lists or detailed data are directly mentioned in the article, it is reasonable to infer that foundry companies exist in Nebraska.

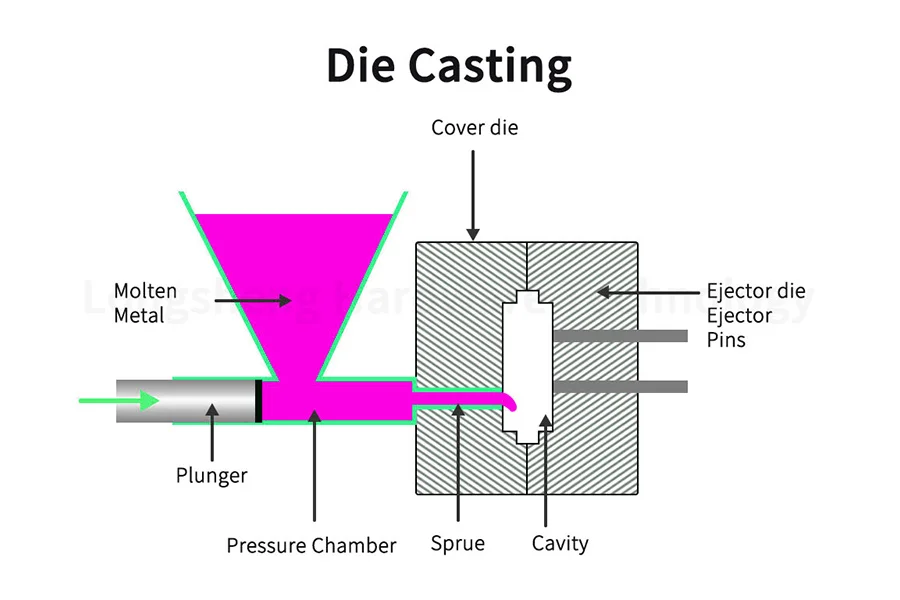

What Is Casting?

Casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. Once solidified, the mold is broken or ejected to retrieve the casting. This method enables the production of intricate and complex components with specific properties.

What Is The Imortance Of Casting In Manufacturing?

Casting is an ancient and important metal forming process, which is widely used in automotive, machinery, aerospace and other fields. Through casting, a variety of metal parts of complex shapes and specifications can be produced to meet the diverse needs of industrial production. Therefore, the casting industry occupies a pivotal position in the manufacturing industry.

What are the advantages and disadvantages of casting?

| Advantages | Disadvantages |

| Ability to produce complex shapes easily | The surface finish may require additional finishing operations |

| Versatility—a wide variety of metals and other materials can be cast | Limited mechanical properties compared to wrought materials |

| Cost-effectiveness, especially for small quantities | The possible presence of casting defects like porosity |

| Capability to produce large-sized castings up to 200 tons | The dimensional accuracy of castings can be compromised due to shrinkage during the solidification process |

| Cost and time savings compared to other manufacturing methods | High initial tooling and equipment costs for certain casting methods |

| Suitable for materials that cannot be mechanically worked | The casting process is typically restricted to metals with lower melting points |

| Simplifies the production of large and heavy components |

Factors affecting the casting cost

Material cost

The material cost of casting is one of the important factors that determine the cost of casting. The cost of different materials varies greatly, such as copper, iron, aluminum, and other materials are very different

Production process

The production process of castings also has an impact on the cost. Different processes require different equipment, processes, consumables and other supplies, resulting in different costs.

Dimensions and weight of castings

The ensions and weight of castings usually affect production costs. Larger size and weight casting require more materials and more complex processes, resulting in a cost increase.4. Design complexity of the castings: The design complexity of the castings will also affect the cost. Designing complex castings often requires more processes and higher technical requirements, thereby increasing the cost

Mass production quantity

The amount of mass production quantity will also affect the cost. Generally speaking, mass production can achieve economies of scale and reduce the cost per unit of a product.

Quality requirements of castings

Quality requirements of castings can also affect the cost. High-quality castings require more stringent production process and inspection requirements, thus increasing the cost.

Market demand and competition

Market demand and competition will also have an impact on the casting cost.market houseWith high demand and fierce competition, casting manufacturers may need to cut prices to keep competition Fight for force.

What are the costs of foundry machining services in Nebraska?

labour cost

- Workers’ wages: the labor costs of smelting, pouring, cleaning and other links are included in the casting process.

- Employee insurance and labor protection costs: These costs also need to be taken into account in labor costs.

cost of material

- Metal materials: the cost of the major metal materials used during the casting process.

- Sand type materials, coatings, etc.: other auxiliary materials required in the casting process.

Equipment cost

- Depreciation expense: the depreciation cost of the casting equipment.

- Maintenance cost: the daily maintenance, maintenance and repair cost of the equipment.

Other Costs

Operational Costs: Facility rents, especially in industrial hubs, can be high. Utility costs, maintenance, and regulatory compliance further add to the operational expenses.

What are the costs of casting processing services in China?

cost of material

- Cost of metal materials: the main metal materials required for casting, such as iron, aluminum, copper, etc., the cost is determined according to the market price and dosage.

- Cost of auxiliary materials: such as sand, clay, paint, etc., these costs should also be included in the material cost consideration.

labour cost

- Workers’ wages: labor costs involving smelting, pouring, cleaning and other links in the casting process, including basic wages, welfare, insurance, etc.

- Overtime pay: The foundry industry often requires overtime and night work, so the extra overtime pay is also a part of the labor costs.

Equipment cost

- Depreciation cost: the depreciation cost of casting equipment is calculated according to the value and service life of the equipment.

- Maintenance cost: the daily maintenance, maintenance and repair cost of the equipment.

cost of mould

Mold making cost: according to the shape and size of the cost of mold making, is an important part of casting processing.

China VS Nebraska Cost Comparison

| COST COMPONENT | CHINA (AVERAGE COST IN $) | Nebraska (AVERAGE COST IN $) |

| Raw Material | $ (Variable) | $ (Variable) |

| Imported Material | $ (Variable) | $ (Variable) |

| Skilled Labor | $7.14/hr | For $20- $50/hr |

| Indirect Labor | $4.31/hr | For $20- $40/hr |

| Local Equipment | $10/hr (avg.) | $85/hr (avg.) |

| Imported Equipment | $15/hr (avg.) | $110/hr (avg.) |

| Operational Costs | $ (Variable) | $ (Variable) |

The advantages of Chinese casting processing service

In recent years, casting processing services in China have become popular due to their many advantages. Next, we’ll discuss why choosing casting processing services in China is the right choice for your business. China casting processing services have the following advantages:

Cost advantage

China is known for its extremely competitive prices, and this advantage is gradually extending to manufacturing. By choosing casting processing services in China, you can significantly reduce production costs without compromising on quality. This is especially beneficial for small and medium-sized businesses with limited budgets.

Talent advantage

China has a large number of highly skilled and experienced teams who are proficient in the latest technologies and skills. These professionals are able to produce high-quality precision castings with extremely high precision and efficiency. By outsourcing your casting processing needs to China, you can tap into this vast talent pool and benefit from their expertise.

Manufacturing capability advantage

Whether you need casting or any other process, you can find the right service provider in China. This versatility allows you to source all your processing needs from one supplier, saving you the time and effort of managing multiple suppliers.

Quick turnaround time

With their advanced machinery and streamlined processes, Chinese manufacturers can deliver your orders within tight timelines. This is critical for companies operating in industries with high demand and short product life cycles.

The reason for choosing Longsheng

No matter what type of casting process service you need, we will help you. With our expertise and industry-leading technology, we can provide you with the highest quality castings.

- Multi-material processing: We have the ability to handle a variety of materials, no matter which material you need to process, we can provide professional solutions.

- Custom Services: Provide custom solutions according to customer design requirements and specifications to ensure that the castings meet their unique needs.

- Competitive price: We provide competitive price and cost-effective solutions to ensure that customers get the greatest advantage in cost control.

- Rapid delivery: We have an efficient production process and flexible production planning that enables us to timely deliver customer orders and meet urgent project needs.

Longsheng ensures the quality of your casting parts through ISO 9001:2015, ISO 9001:14001 and IATF16949.

conclusion

There are casting companies in Nebraska. These companies play an important role in the local economic and social development, and provide an important support and guarantee for the manufacturing industry. In the future, as the manufacturing industry continues to develop and upgrade, the Nebraska foundry company will continue to play an important role, injecting new impetus into the state’s economic development.

FAQs

What are the different grades of cast iron material?

The grade and classification of cast iron materials are mainly based on their chemical composition, fracture color, production methods and tissue properties. Different grades of cast iron materials have different properties and range of application, which can be selected and applied according to specific requirements.

What is the carbon content of cast iron?

The carbon content in cast iron is usually located between 2% and 4%, but the specific carbon content depends on the type and classification of cast iron. Carbon content has a significant impact on the performance of cast iron, while the furnace temperature, smelting time and graphitic agent can also affect the carbon content of cast iron.

What is white cast iron?

White cast iron, commonly known as white cast iron, is a cast iron with a high carbon content (usually between 2.0% and 2.3%). It is characterized by a bright white broken-break opening. This is because almost all of the carbon in white cast iron exists in the form of Fe ₃ C. The carbon is precipitated in the form of carburizing body (namely iron carbonization), and the fracture is bright white.White mouth cast iron is not common in industrial applications due to its hard and brittle properties.

What are the considerations for registering a foundry company in Nebraska?

① Name protection: Although company names are registered in the state, federal trademark registration is considered for nationwide protection.② Tax considerations: Different company types have different tax treatment.③ Continuous compliance: After the establishment of the company, it shall submit annual reports to the state government and pay fees to keep the company active.④ Local license and license: Depending on the nature of the business, it may be necessary to apply for a specific state or local business license, license.⑤ Insurance coverage: consider buying commercial insurance to provide protection for the company’s operation.