In today’s era of economic development, copper and aluminum have become indispensable materials, and in cnc machining technology, copper and aluminum are often used in industrial manufacturing and construction. However, the two metals have different physical and chemical properties, so they are processed differently.

This article will delve into the differences between copper and aluminum, covering their properties, uses, and machining techniques.

Introduction: Characteristics of copper and aluminum

Copper and aluminum have good renewable properties, can be recycled and reused, and are environmentally friendly. They have a wide range of applications in various fields, and the choice of copper or aluminum depends on specific application requirements and performance requirements.

Copper

Copper is a metal material with high strength, low hardness, good toughness, easy machining and forming, good plasticity and conductivity. It is not easily corroded and is a high-quality material for welding and inlaying.

Physical properties of copper

| Physical Property | Value |

|---|---|

| Density | 8.96 grams per cubic centimeter |

| Melting Point | 1,083 degrees Celsius (1,982 degrees Fahrenheit) |

| Boiling Point | 2,567 degrees Celsius (4,653 degrees Fahrenheit) |

| Hardness | 2.5 – 3 (Vickers hardness) |

| Electrical Conductivity | Very high |

| Thermal Conductivity | 385 watts per meter-kelvin |

| Linear Expansion Coefficient | 16.5 x 10^-6 per degree Celsius |

| Color | Reddish-brown |

Chemical properties of copper

| Chemical Property | Description |

|---|---|

| Chemical Symbol | Cu |

| Atomic Number | 29 |

| Atomic Mass | 63.55 atomic mass units (g/mol) |

| Electron Configuration | [Ar] 3d^10 4s^1 |

| Oxidation States | +1, +2 (most common) |

| Reactivity | Relatively stable at room temperature, but gradually oxidizes in the presence of moisture and oxygen |

| Solubility | Soluble in acids, bases, and some organic solvents |

| Alloying Properties | Forms alloys with various metals (such as zinc, tin, aluminum) to enhance hardness and corrosion resistance |

| Chemical Stability | Relatively stable under normal conditions but can be corroded by strong oxidizing agents (such as concentrated nitric acid) and certain acidic solutions |

| Reactivity | Can react with non-metal elements such as sulfur, chlorine, bromine, etc. |

| Common Compounds | Copper oxide (CuO), copper sulfate (CuSO4), copper chloride (CuCl2), etc. |

See this article 【Differences In Different Types Of Copper】 for copper material information

Aluminum

Aluminum is a metal material with low density, high strength, good plasticity, conductivity, and thermal conductivity. It is not easily corroded and is a high-quality material that is easy to process.

Physical properties of aluminum

| Physical Property | Value |

|---|---|

| Density | 2.7 grams per cubic centimeter |

| Melting Point | 660.32 degrees Celsius (1,220.58 degrees Fahrenheit) |

| Boiling Point | 2,470 degrees Celsius (4,478 degrees Fahrenheit) |

| Hardness | 2.0 – 2.9 (Vickers hardness) |

| Electrical Conductivity | High |

| Thermal Conductivity | 237 watts per meter-kelvin |

| Linear Expansion Coefficient | 23.1 x 10^-6 per degree Celsius |

| Melting Heat | 397.5 joules per gram |

| Specific Heat Capacity | 0.897 joules per gram-degree Celsius |

| Tensile Strength | 70 – 700 megapascals |

Chemical properties of Aluminum

| Chemical Property | Description |

|---|---|

| Chemical Symbol | Al |

| Atomic Number | 13 |

| Atomic Mass | 26.98 atomic mass units (g/mol) |

| Electron Configuration | [Ne] 3s^2 3p^1 |

| Oxidation States | +3 (most common) |

| Reactivity | Reacts with strong acids and bases, but forms a protective oxide layer that prevents further reaction with air and water |

| Solubility | Insoluble in water |

| Alloying Properties | Forms alloys with various metals, resulting in improved strength, hardness, and other properties |

| Combustibility | Non-combustible |

| Corrosion Resistance | Exhibits good corrosion resistance due to the formation of a thin, protective oxide layer on the surface |

| Reactivity with Halogens | Reacts with halogens (such as chlorine and fluorine) to form aluminum halides |

| Common Compounds | Aluminum oxide (Al2O3), aluminum chloride (AlCl3), aluminum sulfate (Al2(SO4)3), etc. |

See this article 【6061 Best Practices For CNC Machining Of Aluminum】for aluminum material information

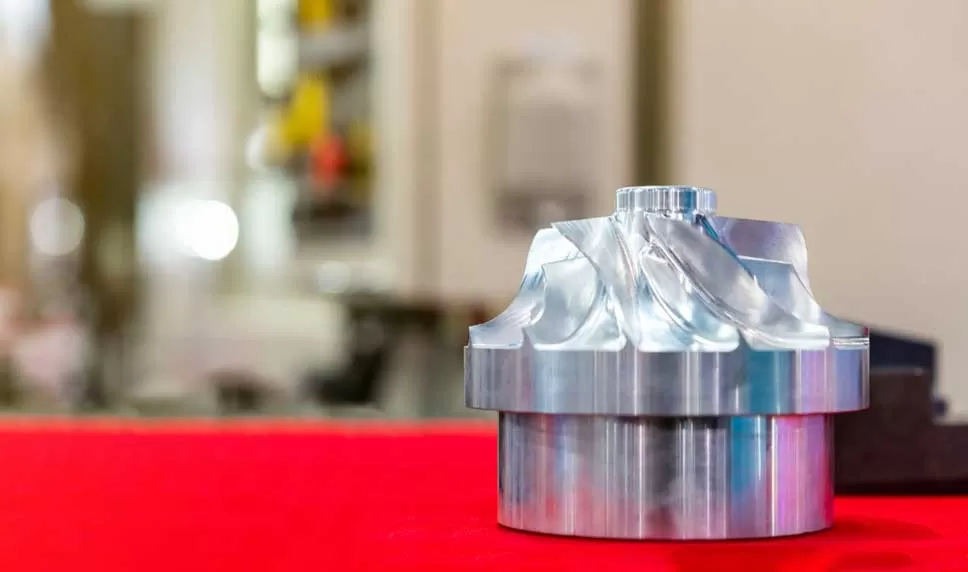

machining methods for copper and aluminum

machining copper and aluminum have various material properties and applications, and multiple machining methods can be used to produce products of different shapes and sizes. The following are common methods for machining copper and aluminum

Method of machining copper

Copper is a metal material with elasticity and good conductivity, which has good cutting performance and is easy to machine. Here are several methods for machining copper:

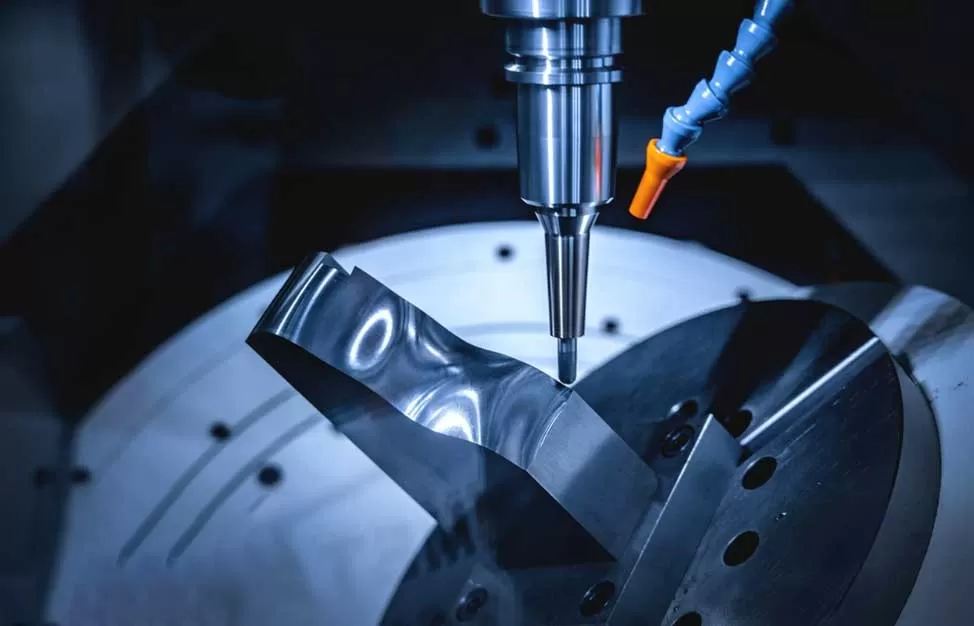

1.milling machining

The copper material is cut to the desired shape and size using milling machines and tools. Milling is suitable for the machining of flat, curved and complex shapes of copper.

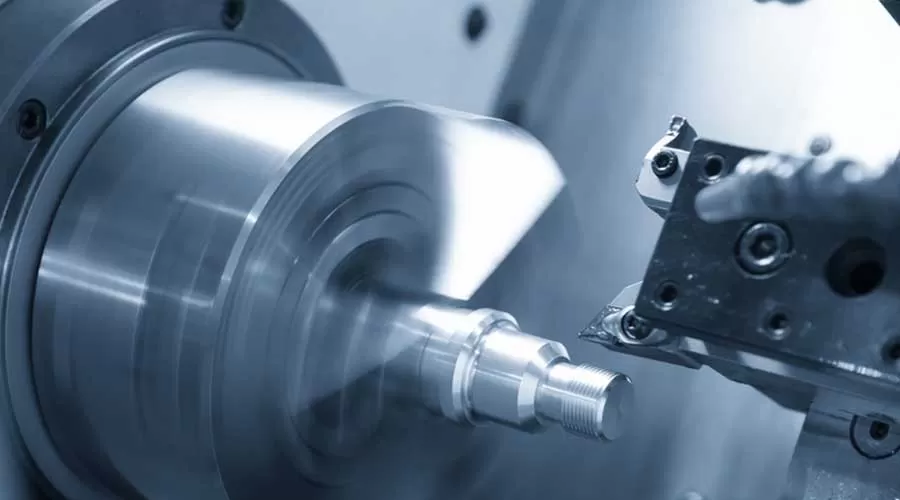

2.turning machining

The rotating copper material is cut using lathes and tools to obtain the desired diameter, length and surface quality. Turning is suitable for the manufacture of shaft parts and cylindrical parts.

3.stamping machining

The copper sheet is stamped into parts of the desired shape using punches and molds. Stamping is suitable for mass production and machining of copper parts with simple shapes.

4.Sheet Metal Fabrication

Cutting, bending, punching and other processes are used to process copper sheets into parts of the desired shape. Sheet metal fabrication is suitable for the manufacture of thin sheets or copper parts with complex shapes.

These methods can be selected according to the specific copper part requirements and the feasibility of the machining process. When choosing the right machining method, we need to consider the complexity of parts, size requirements, production batch and cost effectiveness, and other factors, in Longsheng technology, we have a professional technical team, if you need copper machining and manufacturing services and a full range of design and rapid prototype production services, please contact us

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com

Method of machining aluminum

Aluminum is a kind of metal material with good thermal conductivity, good durability, corrosion resistance and portability. machinng aluminum is relatively easy, the following are several commonly used machinng aluminum methods:

1.milling machinng

Milling is the most common method used in aluminum machinng . The milling cutter is usually fixed by several gears and can be drilled, chamfered, and face-milled. It is characterized by the machinng of aluminum parts that can be created in various shapes

2.stamping machinng

Stamping is to press aluminum plate, aluminum film and other materials into the desired shape and size in the mold by punching machine and other equipment. This method is mainly suitable for the production of small and medium sized aluminum parts

3.Turning machinng

The rotating aluminum material is cut using lathes and tools to obtain the desired diameter, length and surface quality. Turning is suitable for the manufacture of shaft parts and cylindrical parts.

4.drawing

Stretching is the process by which aluminum is stretched to change its shape and size. The aluminum is stretched at a controlled temperature to achieve the desired shape and strength. Reverse stretching can obtain its reverse shape.

We provide aluminum parts machining services, whether you want to develop new products, improve old products, or customize the desired products, we can provide you with comprehensive services. Please feel free to contact us and we will be happy to serve you.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com

difference between copper and aluminum

Although both copper and aluminum are important metals, there are many differences between them, and understanding these differences can better understand their properties and application areas, which helps us to better use them

Comparison of physical properties of copper and aluminum

Copper and aluminum are both very common metals, and their physical and chemical properties are very similar. First, let’s look at their physical properties:

| Physical Property | Copper | Aluminum |

|---|---|---|

| Density | 8.96 g/cm³ | 2.70 g/cm³ |

| Melting Point | 1,083°C | 660°C |

| Thermal Conductivity | 401 W/(m·K) | 237 W/(m·K) |

| Electrical Conductivity | 59.6 × 10^6 S/m | 37.7 × 10^6 S/m |

| Young’s Modulus | 110-128 GPa | 70-79 GPa |

| Hardness | 3 Mohs | 2.75 Mohs |

| Coefficient of Thermal Expansion | 16.5 × 10^(-6) /K | 23.1 × 10^(-6) /K |

| Application | Electrical, plumbing, construction, art | Aerospace, automotive, construction, packaging |

These values are estimates based on general properties, and actual values may vary depending on the sample, purity, and manufacturing process.

Comparison of chemical properties of copper and aluminum

Copper and aluminum are also very different in their chemical properties. The following is a comparison of the differences between the two materials:

| Chemical Properties | Copper | Aluminum |

|---|---|---|

| Reactivity | Moderate | Moderate |

| Oxidation | Not easily oxidized | Not easily oxidized |

| Acidic Reaction | Affected by dilute sulfuric and nitric acid | Affected by concentrated alkaline solutions and hot concentrated sulfuric acid |

| Alkaline Reaction | Does not directly react with alkalis | Can react with strong alkalies |

| Oxidation States | +1, +2 | +3 |

| Oxides | Copper oxide (Cu2O, CuO) | Aluminum oxide (Al2O3) |

| Solubility | Copper ions soluble in water | Aluminum ions insoluble in water |

| Corrosiveness | Relatively low corrosion,resistant to most non-oxidizing acids | Relatively high corrosion resistance,but susceptible to hot concentrated alkaline solutions |

| Corrosion Products | Verdigris (basic copper carbonate) | Aluminum oxide film (Al2O3) |

| with Air | Gradual oxidation when exposed to air | Formation of oxide film when exposed to air |

Comparison of Application Fields of Copper and Aluminum

Copper and aluminum are two widely used metal materials that have their own applications in different fields. The following is a comparison between copper and aluminum in the application field:

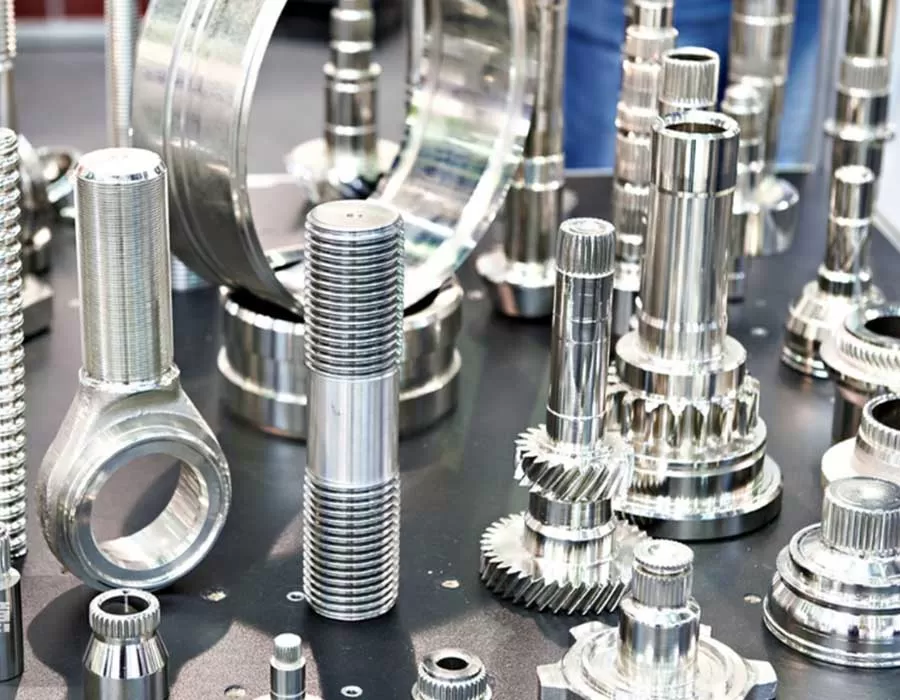

Application areas of copper

1.Electronic and electrical industry: copper wires, cables, motor coils, electronic components, etc.

2.Manufacturing and Mechanical engineering: copper pipes, copper alloy parts, bearings, gears, etc.

3.Metallurgy and chemical industry: copper reactors, heat exchangers, catalysts, etc.

4.Architecture and architectural decoration: copper roofs, doors and Windows, sculptures, etc.

5.Musical equipment: brass instruments such as horns, brass instruments, etc.

6.Food machining and catering: copper POTS, copper cookware, tableware, etc.

7.Jewelry and ornaments: copper jewelry, ornaments, works of art, etc.

Applications of aluminum

1.Automotive industry: aluminum body, engine parts, wheels, radiators, etc.

2.Aerospace industry: aluminum alloy structural parts, aircraft shell, engine parts, etc.

3.Packaging industry: aluminum cans, food packaging, pharmaceutical packaging, etc.

4.Building and building decoration: aluminum doors and Windows, curtain walls, aluminum profiles, etc.

5.Electronic and electrical industry: aluminum radiators, electronic equipment enclosures, wires, etc.

6.Railway and rail transit: aluminum alloy car body, track structure, train interior, etc.

7.Home and furniture: Aluminum household items, furniture, kitchenware, etc.

Comparison of copper and aluminum prices

In terms of price, aluminum is cheaper than copper. The production cost of aluminum parts is relatively lower, and the following is the price and cost comparison table of the two materials:

| Average Price (per ton) | 2019 | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|

| Copper | $6,000 – $6,500 | $5,600 – $6,000 | $9,000 – $10,000 | $9,500 – $10,500 | $9,200 – $10,200 |

| Aluminum | $1,700 – $1,900 | $1,500 – $1,700 | $2,200 – $2,500 | $2,300 – $2,700 | $2,400 – $2,800 |

Copper price trend analysis

Copper is an important base metal, and its price fluctuates greatly. In recent years, copper prices have shown a volatile upward trend. At the beginning of 2019, the price of copper was around $6,000 per ton, and by 2021, it briefly exceeded $9,000 per ton. Among them, the impact of the epidemic on the price of copper is very obvious, and the price of copper in 2020 is very volatile. But overall, copper still has room to rise for some time to come.

Aluminum price trend analysis

In contrast, aluminum is a relatively stable metal with relatively small price fluctuations. In 2021, aluminum prices are around $2,200 per ton. This price is relatively low, but it is also one of the most volatile in recent years. But it will reach around $1,700 per ton in 2020. Overall, the change in aluminum prices is not large, and there will be no big ups and downs in the future.

conclusion

While the price of aluminum is relatively low, the price of copper is higher. At the beginning of 2019, the price of copper was about $6,000 per ton, while the price of aluminum was about $1,700 per ton during the same period. This price varies widely, but over time, in 2021, the price of copper is more than $9,000 per ton, while the price of aluminum is around $2,200 per ton.

machining copper and aluminum finishes and post-treatment options

After machining copper and aluminum, finishing and post-treatment can be carried out to improve their appearance, protective performance, or meet specific needs. The following are some common finishing and post-treatment options for machining copper and aluminum:

Finish options in copper and aluminum materials

Copper and aluminum, whether used in processes or finished products, are a very good choice for final use with finishes. Here are a few common finish options for copper and aluminum materials:

1.Electroplating

Electroplating is a common finish option that makes the surface of copper and aluminum materials shiny and more resistant. A chrome-plated, secure metal sink is also a prudent approach. Chromic, black chrome, chromate resin and other materials are optional, depending on the color and texture you need.

2.Anodizing

In oxidation technology, voltage oxidizes aluminum or other metals such as zinc to form a polar film, forming a hard and sealed layer on the original surface, which can protect the metal well and present a beautiful appearance. In addition, anodizing is also an important method to improve the corrosion resistance and corrosion resistance of metals.

See this article 【Anodizing Finish:Applications Of CNC Machining Parts】 for anodizing information

3.Spray Painting

Spraying is a method of evenly distributing spray over the surface of an object to improve the color and appearance of a metallic material. You can choose from a variety of colors and textures to make your finished product look more professional.

Post-treatment options for copper and aluminum materials

The better the post-treatment of the material, the better the texture of the finished silk. The following are several post-treatment options available for copper and aluminum materials:

1.Polishing

Polishing is a method to remove the convex part of the surface and improve the surface quality of the material. Polishing requires the use of commercially available polishes and polishing machines. Polishing can not only make the surface of the material more smooth, but also reduce irregularities and small scratches on the surface of the material.

2.Sanding

Sanding is an important technology in the manufacturing process of copper and aluminum finished products, sanding can obtain different polishing effects, from quite beautiful to quite appearance of the particle effect, improve the finish treatment of copper and aluminum materials, improve the texture of the product.

3.Sand Blasting

Sandblasting is a manufacturing technique in which high-speed sand particles are embedded on the surface of an object. Using an adjustable nozzle, millions of high-speed sand particles are sprayed per second, adjusting the accuracy and intensity of the sand blasting by adjusting the pressure and reaching the exact Angle.

If you are looking for high-quality machining copper and aluminum finishes and post-treatment options, please contact us! Our online machining services provide one-stop surface finishing services, making your products more beautiful and durable. We look forward to providing you with the highest quality service

Starting with machining copper and aluminum services now

Machining copper and aluminum? At Longsheng Technology, you can make your ideas become reality, whether you need to produce small batches of products or need customized mass production, we can provide you with fast, efficient and high-quality machining services.

Our machining copper and aluminum services not only meet your production needs, but also enhance the quality and added value of your products. Please contact us and we will provide you with the best service and solutions.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com

FAQ

Generally speaking, cutting aluminum is easier than cutting copper. This is because aluminum is softer and easier to work with, especially under high heat conditions.

Scrap copper and aluminum can usually be reused through recycling. In the process of handling waste, attention needs to be paid to procedures such as sorting, removing foreign objects, removing pollution, smelting, and recycling.

We offer many types of copper and aluminum machining . These include milling, stamping, turning, extrusion and drawing. Each machining method has different advantages and applications, and we can help you choose the best machining method for you according to your specific needs.

The copper and aluminum machining we offer can manufacture many different types of products, such as electrical parts, machinery parts, aircraft and automotive parts, coolers and other industrial and household items. As a complete machining service provider, we can manufacture custom products to your specific needs and specifications.